A laser additive manufacturing process for k465 nickel-based superalloy structural parts

A nickel-based superalloy, laser additive technology, applied in the direction of additive processing, additive manufacturing, process efficiency improvement, etc., can solve problems such as difficult to prepare, to improve the overall toughness, suppress the appearance of micro cracks, reasonable process control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0035] (1) process parameter: each embodiment process parameter is as shown in table 2:

[0036] Table 2 process parameter table

[0037] Process parameters

Example 1

Example 2

Example 3

Comparative example 1

laser power

1600W

1600W

1800W

1000W

scanning speed

6mm / s

6mm / s

6mm / s

6mm / s

Powder feeding rate

1.0g / min

1.5g / min

2g / min

1.5g / min

scanning method

interlaced scanning

Overlap rate

40%

45%

50%

45%

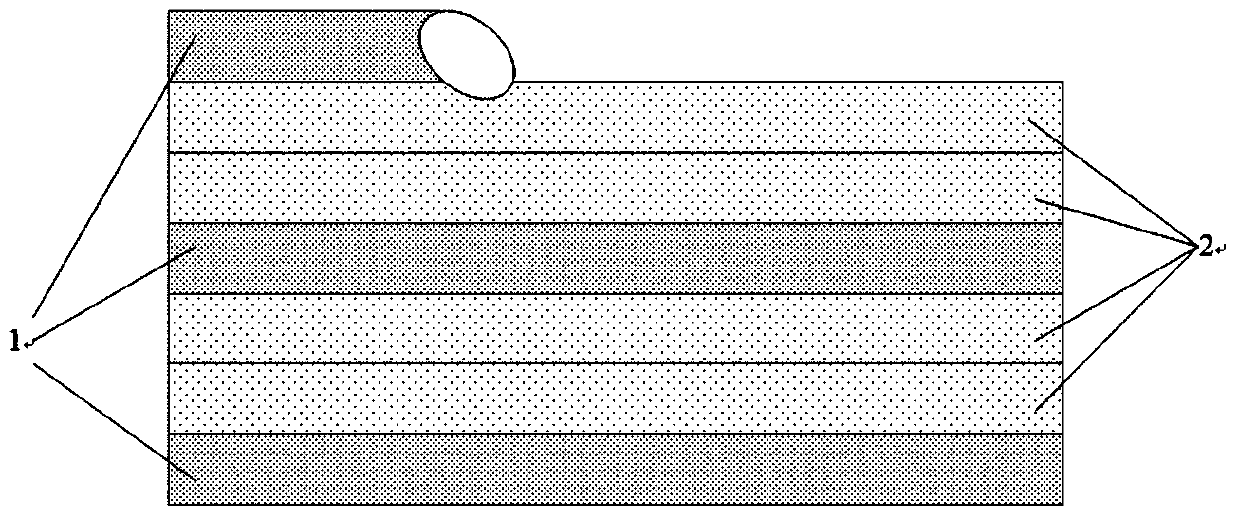

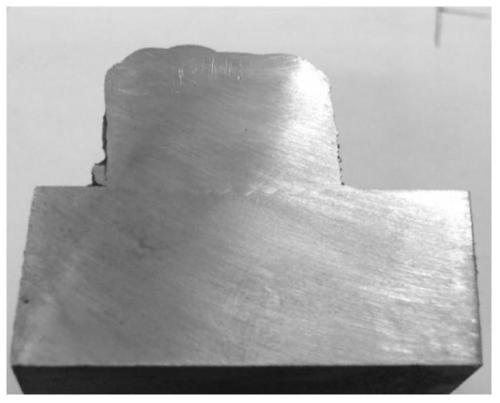

[0038] (2) Laminated structure: 1 layer of K465 alloy and 2 layers of Stellite6 alloy are alternately stacked, such as figure 2 As shown, one layer of K465 superalloy is first formed, then two layers of Stellite 6 superalloy are formed, and then one layer of K465 superalloy is formed, and so on, and the parts with composite alloy structure are finally formed at one time. Such as image 3 As shown, there is no cra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com