Non-loss inspecting device and method for precisive pipe internal-threaded core

A technology of internal thread core and non-destructive testing, which is applied in the direction of measuring devices, analyzing materials, and material analysis through optical means, and can solve the problem of non-destructive testing of precision copper tube internal thread cores, poor flexibility in use, and long process cycle and other problems, to achieve the effect of compact structure, short process cycle and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

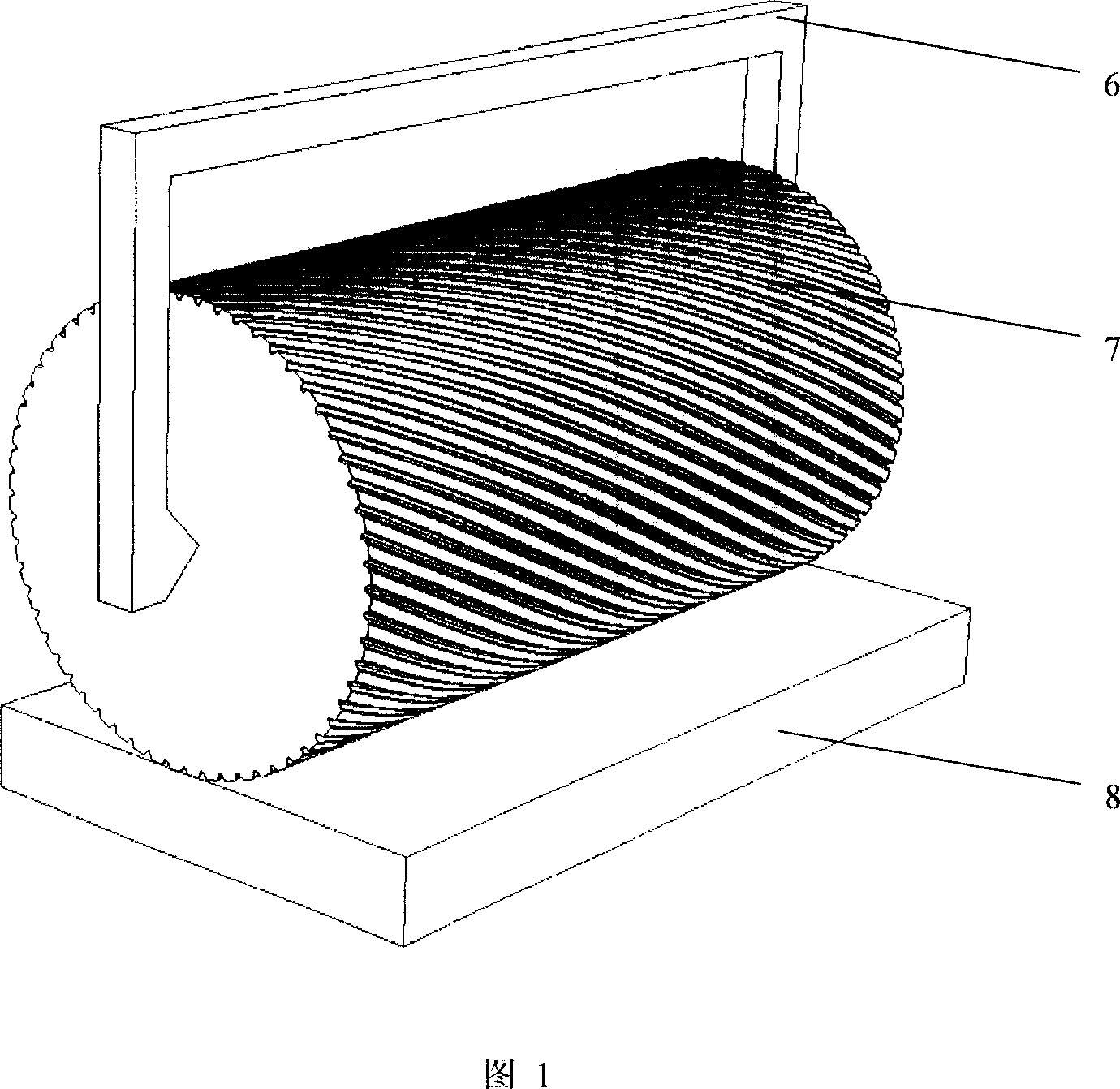

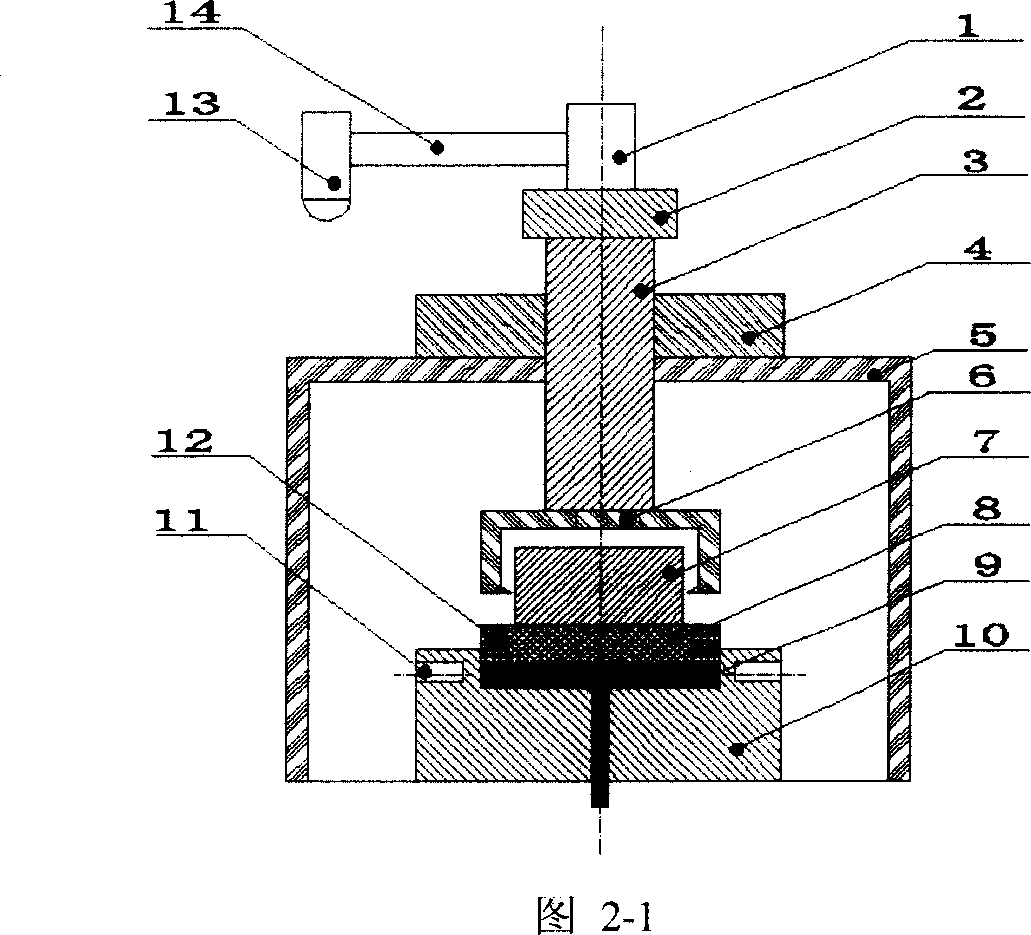

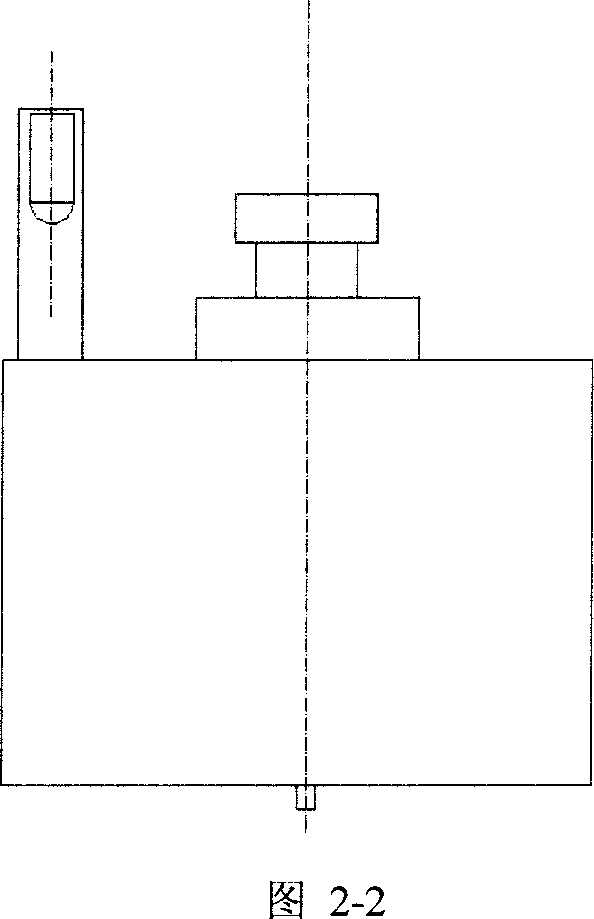

[0038] Hereinafter, this embodiment will be described in detail with reference to Figs. 1, Figs. 2-1, 2-2, and 2-3.

[0039]The detection device of the present invention consists of a supporting rod 1, a top cover 2, a screw 3, a limit sleeve 4, a PLC temperature control heating jacket 5, a clamp-shaped indenter 6, an internal thread core 7, a bulk amorphous alloy 8, a top The rod 9, the base 10, the temperature measurement blind hole 11, the limit insert 12, the detection element 13 and the connecting rod 14. The detection element 13 adopts a high-power optical microscope, and the support rod 1 is connected to the high-power optical microscope through the connecting rod 14 , Used for rotating positioning observation. The lower end of the top cover 2 is connected with the screw 3 for applying the output displacement. The neck of the screw 3 is provided with a limiting sleeve 4 to avoid damage to the clamp-shaped indenter 6 and the internal thread core 7 due to excessive stroke. Th...

Embodiment 2

[0049] Hereinafter, this embodiment will be described in detail with reference to Fig. 1 and Figs. 3-1, 3-2, and 3-3.

[0050] The detection device is different from Embodiment 1 in that: the detection element 13 is a high-resolution camera.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com