Job shop operation planning and rescheduling method for complex aeronautical equipment structures

A technology for job planning and structural parts, applied in computing, instrumentation, data processing applications, etc., can solve problems such as rapid response to sudden disturbances in discrete workshops that do not consider planning-scheduling connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

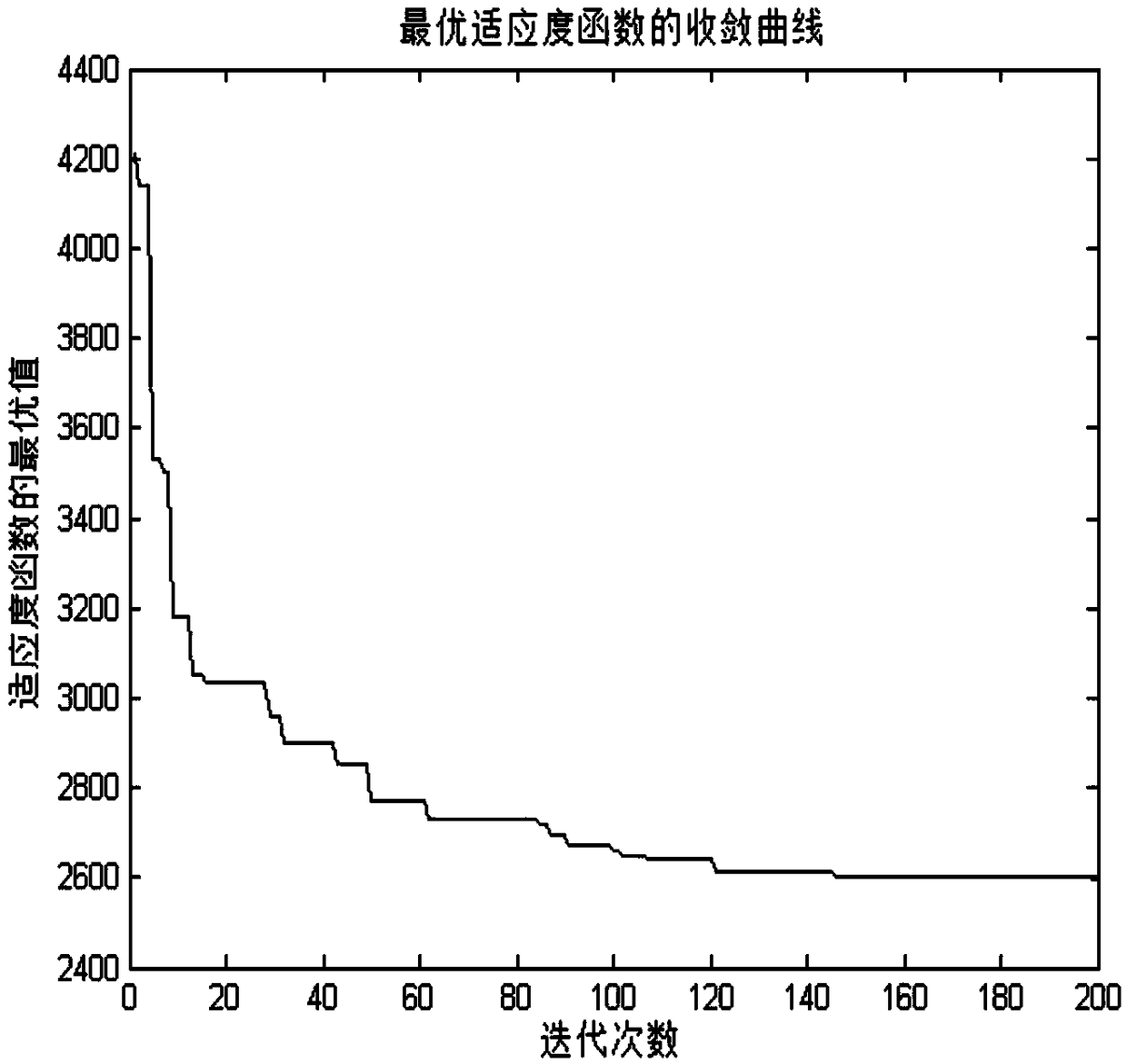

[0071] This implementation mode is to apply the above method to an example of production scheduling in a certain complex equipment structural parts workshop, and to verify the effectiveness of the model and algorithm in actual production through the simulation of production scheduling with sufficient resources and production scheduling with disturbances. Practicality in scheduling. The method of the present invention has been realized with MATLAB R2014a.

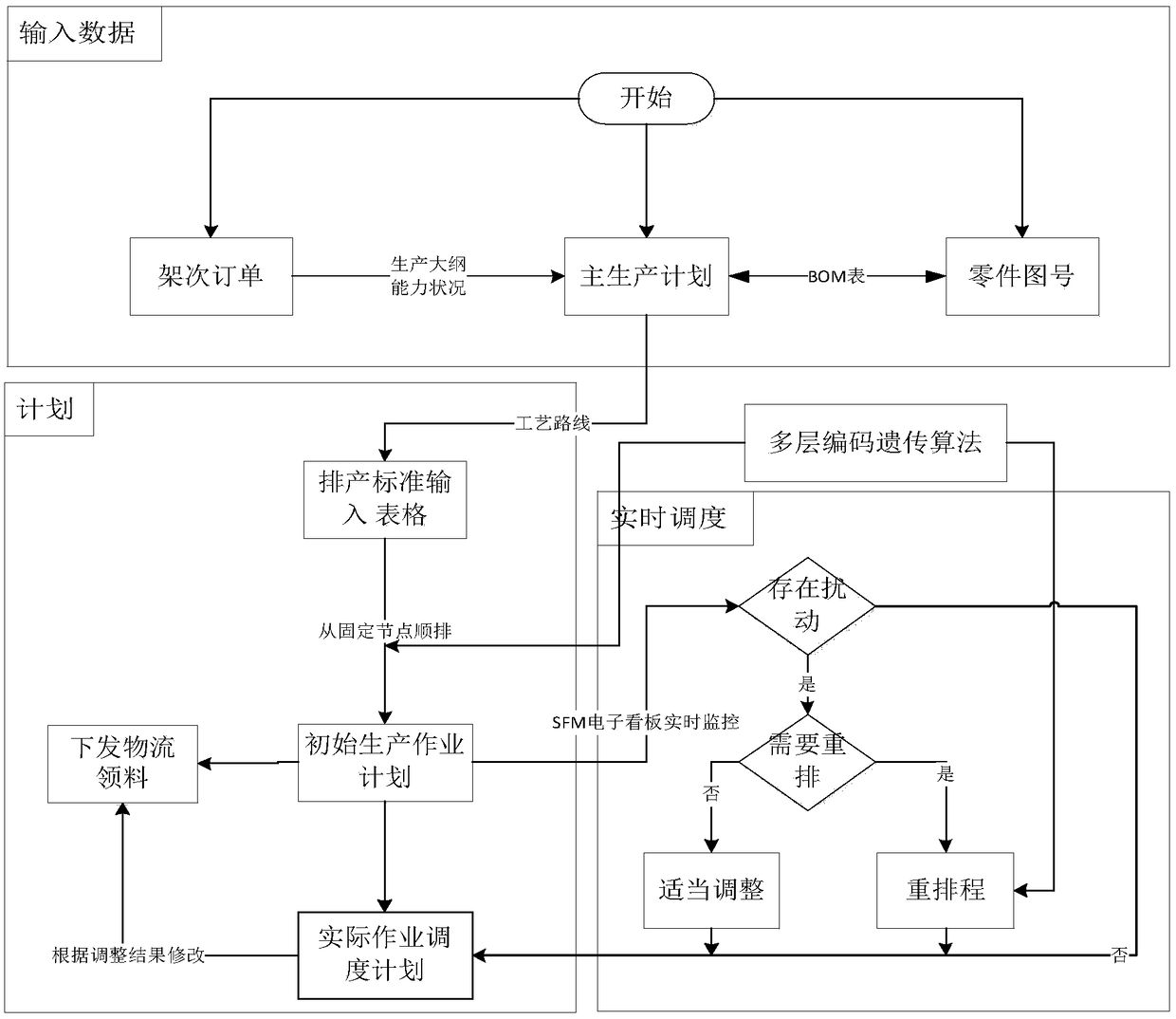

[0072] The implementation process is as follows figure 1 As mentioned above, the planning part can be mathematically described as having N tasks to be processed, and the batch size of each task is p. The jth process of each order task i m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com