Tobacco leaf intensive baking method

A technology for intensive curing and tobacco leaves, which is applied in the fields of tobacco, tobacco preparation, and application, and can solve the problems of uncoordinated temperature and humidity of tobacco leaf curing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0087] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0088] The tobacco leaf intensive baking method of the present embodiment comprises the following steps:

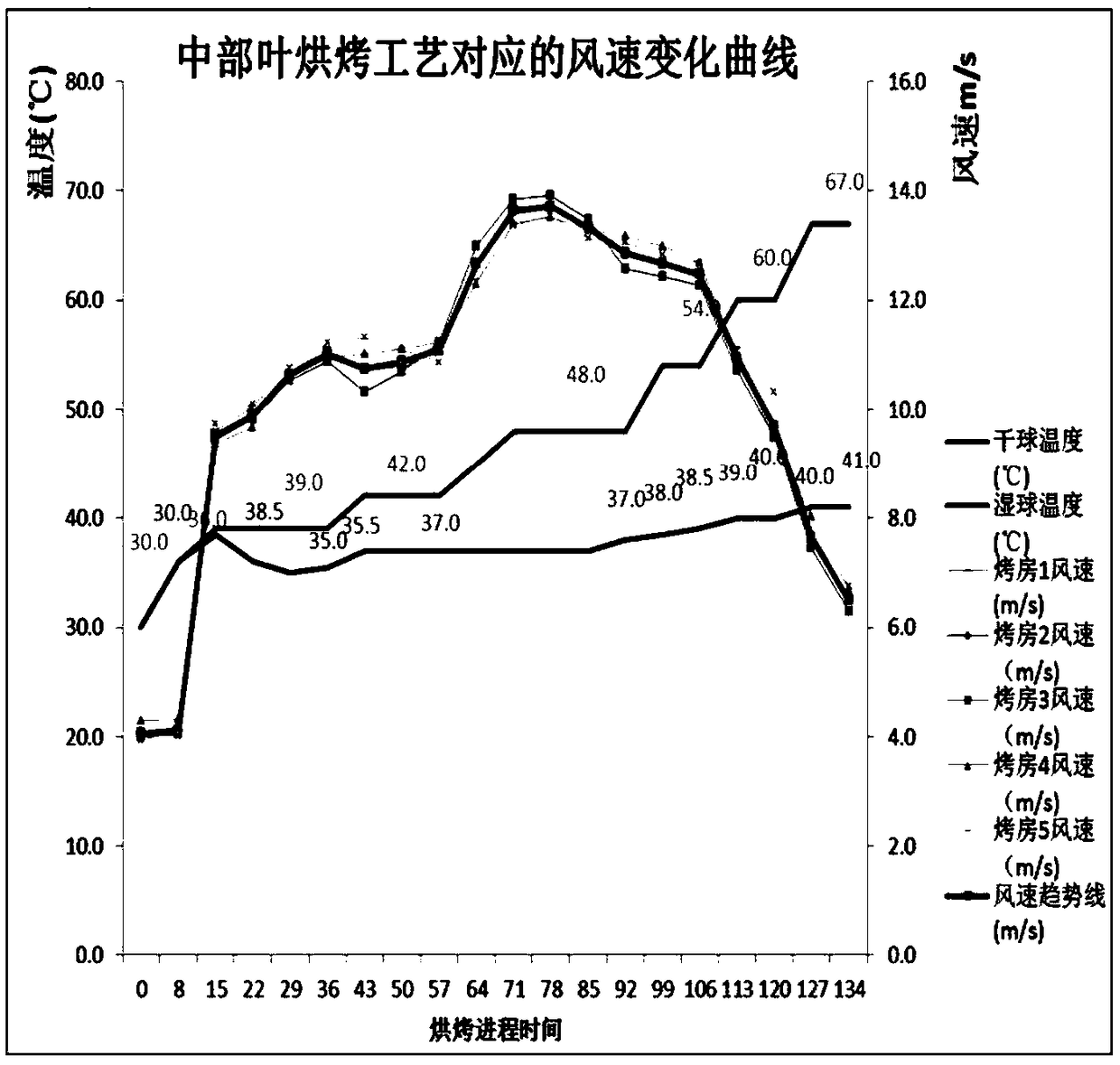

[0089] Step 1: Determine the location and maturity of the tobacco leaves, and classify the tobacco leaves into: upper normal mature tobacco leaves, middle normal mature tobacco leaves and lower normal mature tobacco leaves; Step 2: Classify the three types of tobacco leaves in different curing rooms according to their respective curing conditions Individual roasting within the roasting parameters,

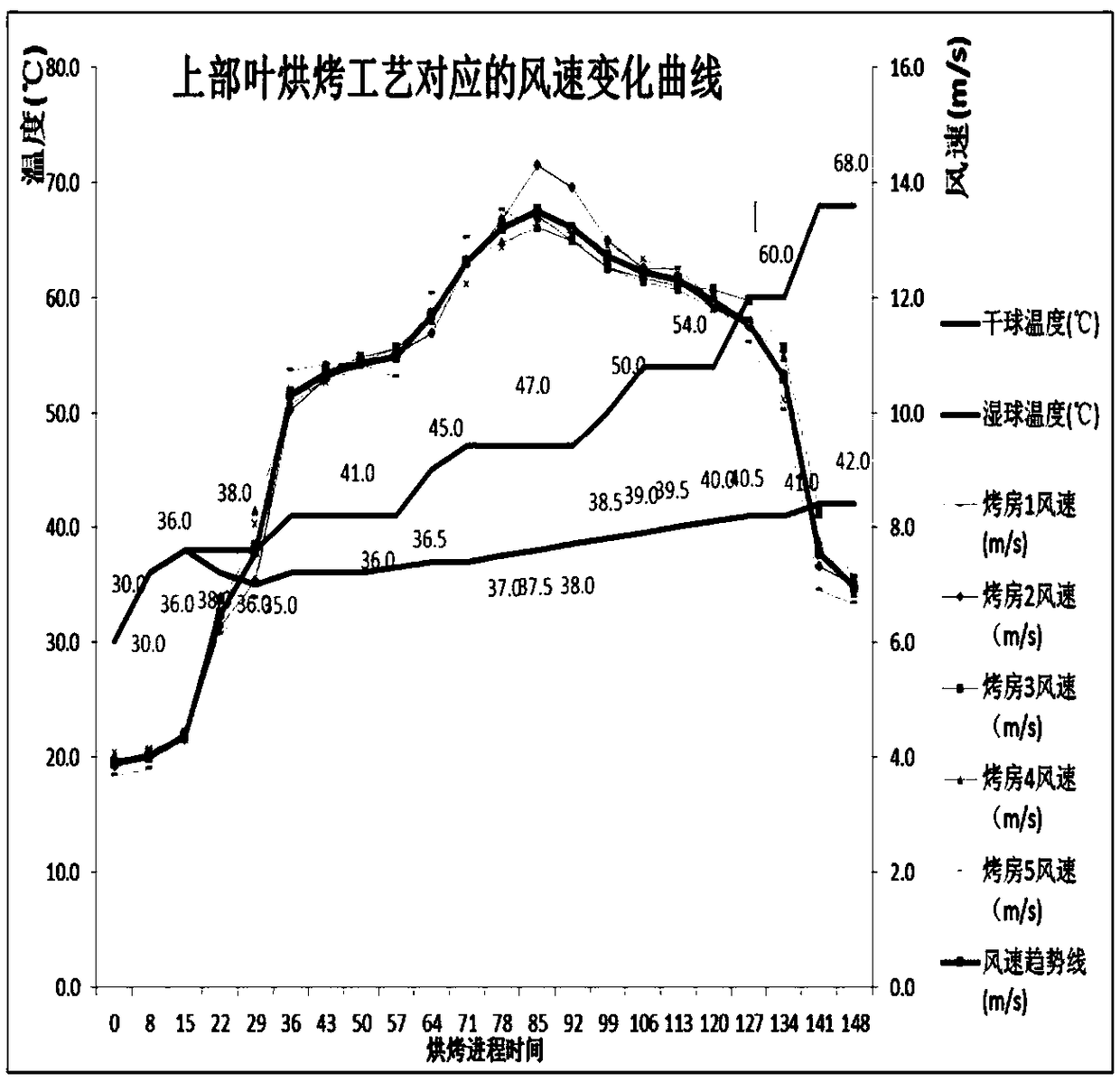

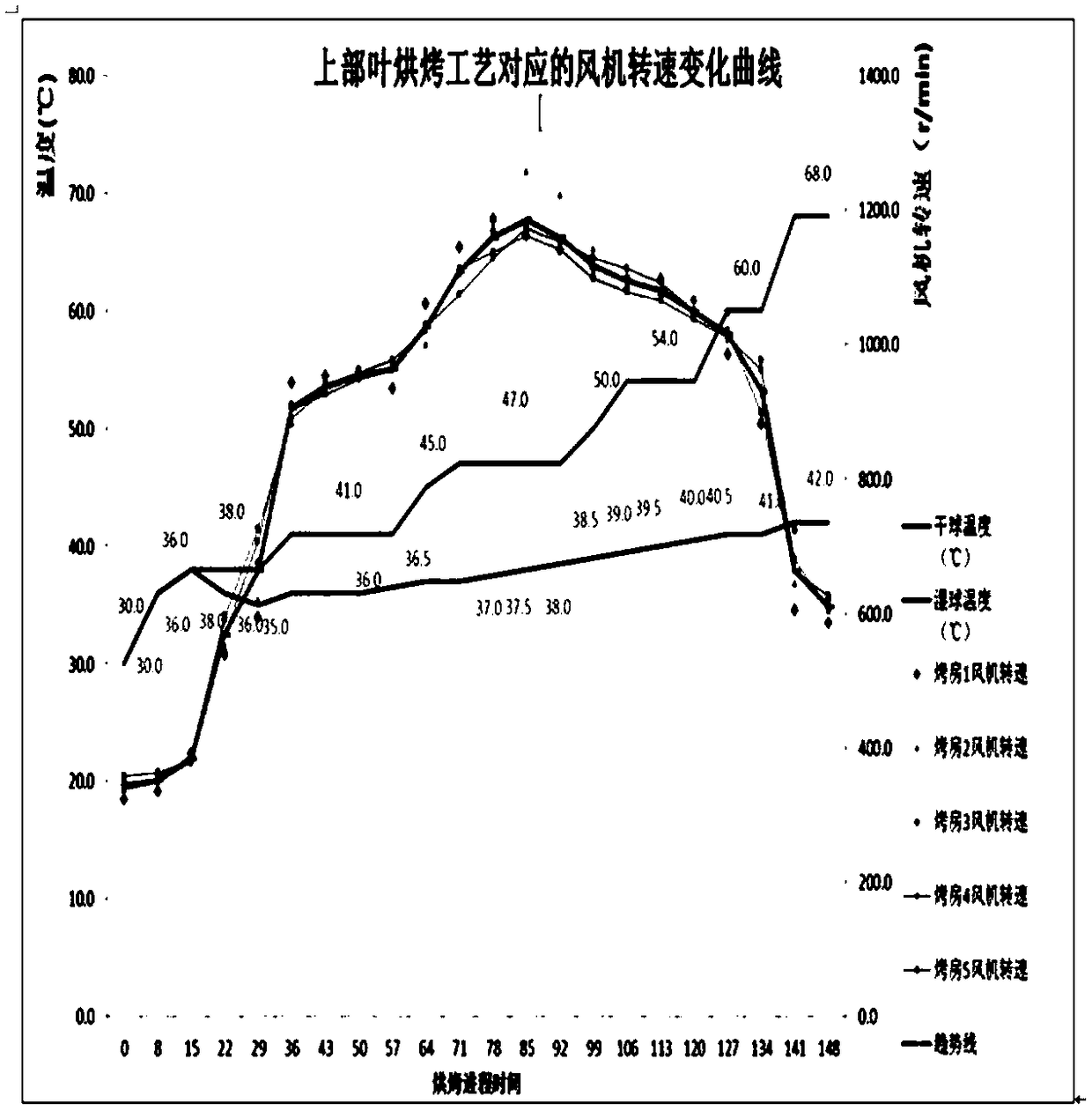

[0090] Wherein: the curing parameter control process of upper normal ripe tobacco leaf is as follows:

[0091] (1) In the oven in the initial state, the dry bulb temperature is kept at 30°C, the wet bulb temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com