Petroleum pipeline dredger

A technology for oil pipelines and dredgers, which is applied in the direction of chemical instruments and methods, cleaning hollow objects, cleaning methods and appliances, etc. It can solve the problems of long time consumption, high labor intensity of dredging oil pipelines, and non-universal dredging equipment, etc., to achieve intelligent cleaning , easy to carry, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

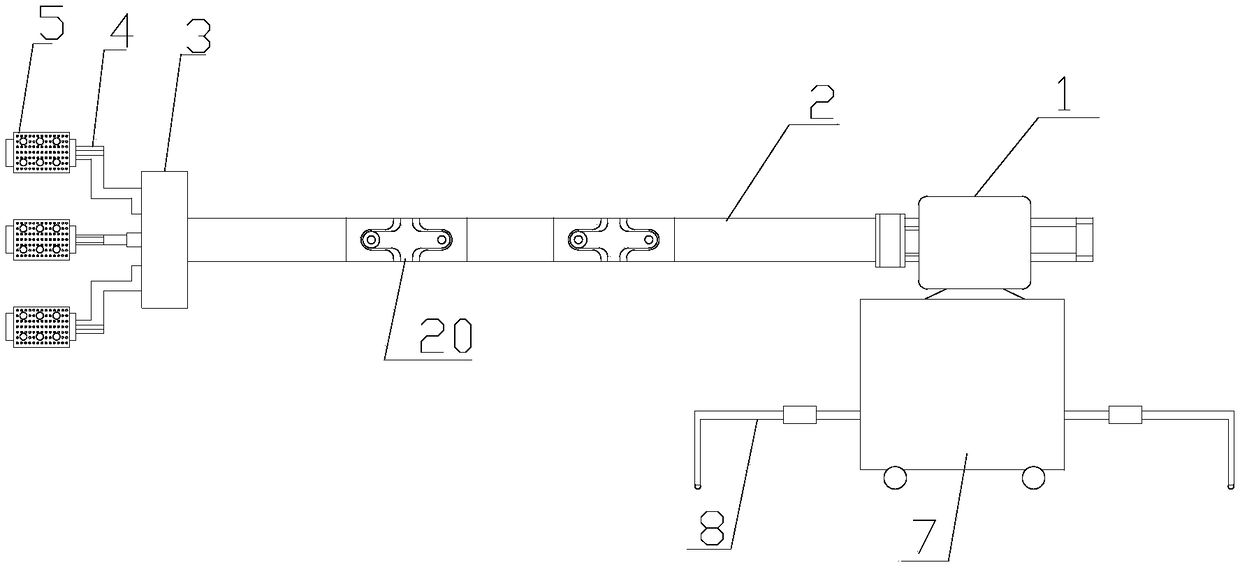

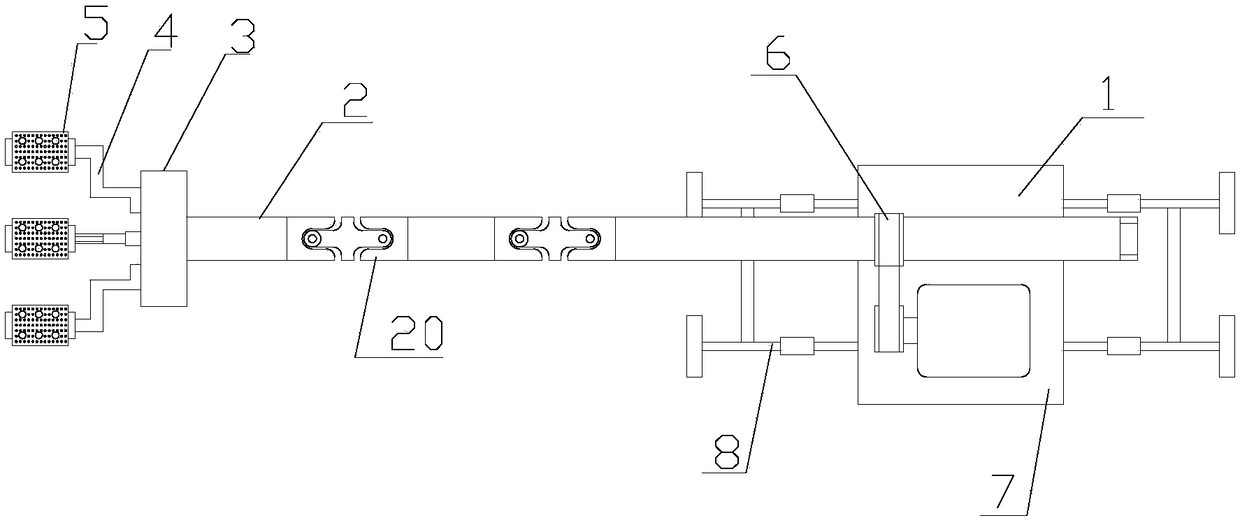

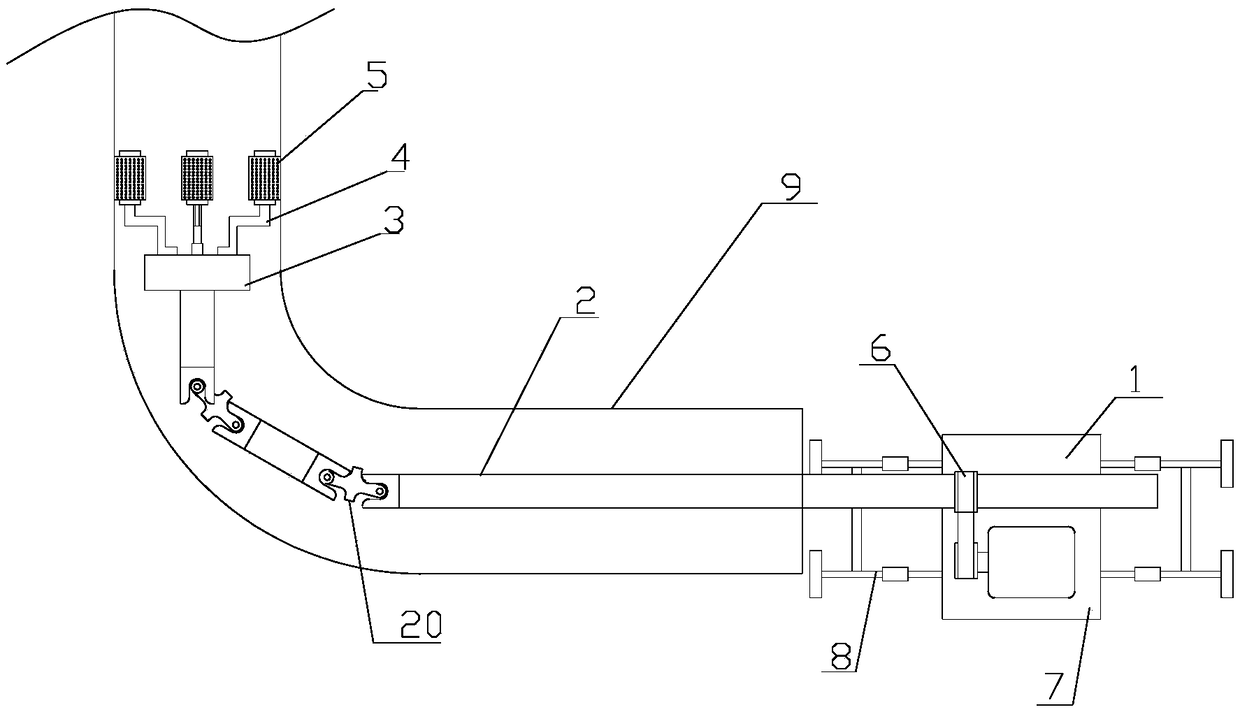

[0025] Such as Figure 1~2 Shown as a preferred embodiment, the motor 1 of the oil pipeline dredger is installed on the base 7, the motor 1 is connected to the rotating shaft 2, the rotation of the motor 1 drives the rotating shaft 2 to rotate, the rotating shaft 2 is fixedly connected to an adjustable chuck 3, and the rotating shaft 2 The axis coincides with the axis of the adjustable chuck 3, and a plurality of connecting claws 4 are arranged on the end face of the adjustable chuck 3. The adjustable chuck 3 and connecting claws 4 are similar to the three-jaw adjustable chuck used on the machine tool The radial position of the connecting claws 4 on the end face of the adjustable chuck 3 can be adjusted by the adjusting device, so as to realize the "opening" and "shrinking" of the multiple connecting claws 4 in the radial direction. For example, by setting the connecting claw 4 and the adjustable chuck 3 through the threaded connection of the end face, and setting the limit de...

Embodiment 2

[0029] Such as Figure 4 As shown, the adjustable chuck 3 of this embodiment uses the second motor 34 to adjust the position of the connecting claw 4 in the radial direction of the adjustable chuck. Specifically, the adjustable chuck 3 includes a fixed disk 31, a rotating disk 32, and a blocking disk 33; the fixed disk 31, the rotating disk 32, and the blocking disk 33 are coaxially arranged; one end of the fixed disk 31 is connected to the rotating shaft 2. The other end of the fixed disc 31 is provided with a cavity 311 for accommodating the turntable 32, the turntable 32 is placed in the cavity 311, and the turntable 32 and the fixed disc 31 are rotatably connected, and the rotatably connected This is achieved by inserting the matching shaft 310 on the fixed disk 31 into the matching hole 321 of the rotating disk 32 . The turntable 32 has an end face thread 320; the connecting claw 4 consists of three parts, the first part 40 has an end face matching thread 400 matched wit...

Embodiment 3

[0031] The friction head 5 can be detachably connected with the connecting claw 4, so that when the friction head 5 is damaged, it can be replaced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com