Device for skew rolling the tubular or rod shaped rolling piece

A rolled piece and rod-shaped technology, applied in the field of skew rolling equipment, can solve the problems of increasing the rolling speed, increasing the wear, and uneven operation of the rolling piece, avoiding the rotation of the rolling piece, reducing the centrifugal force, and improving the productivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

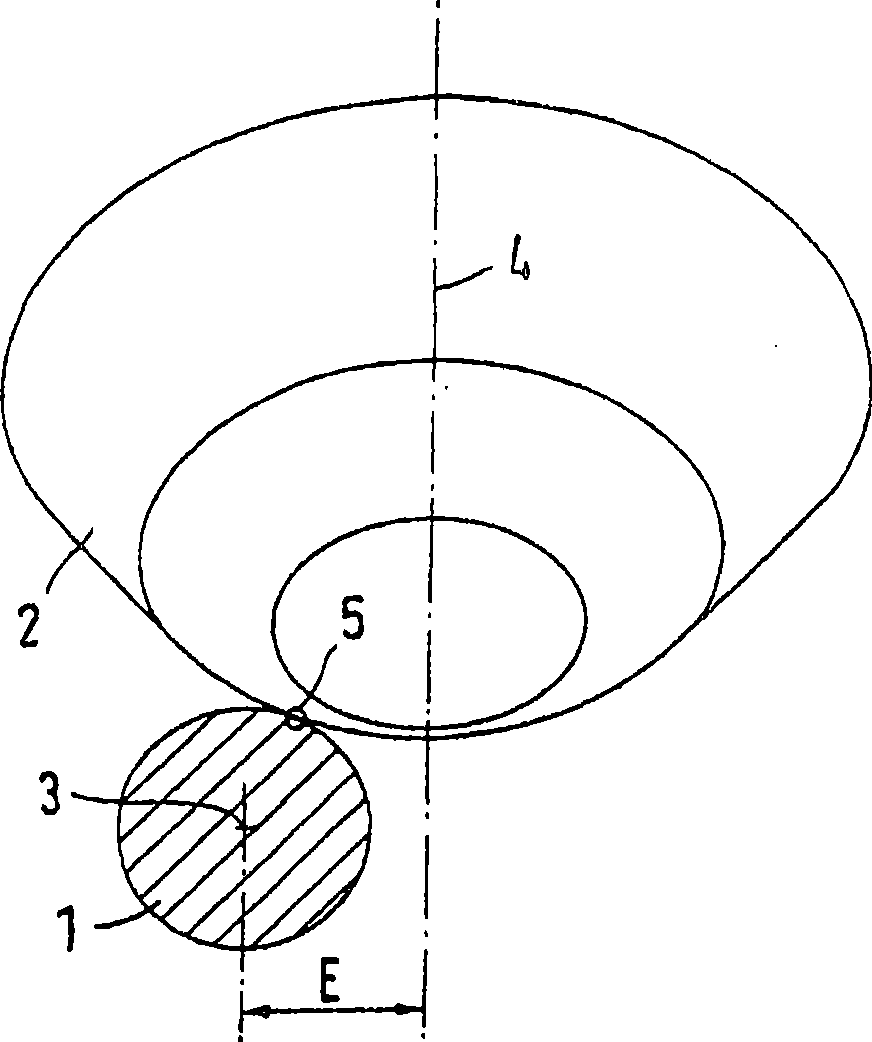

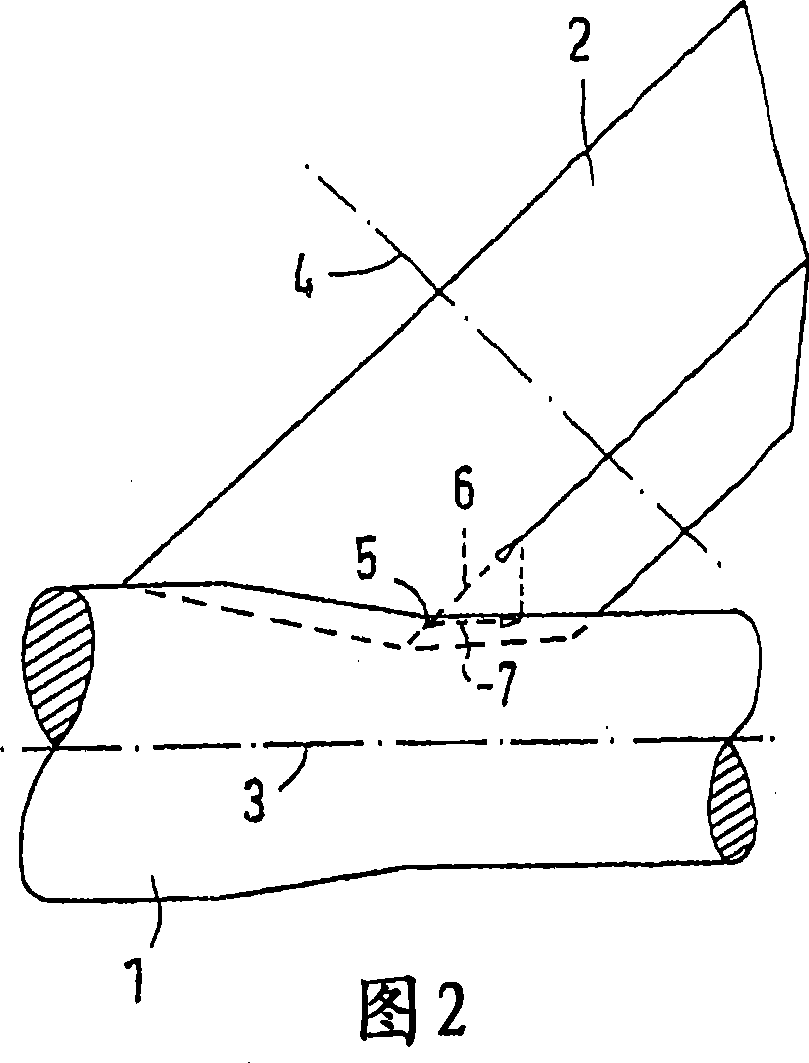

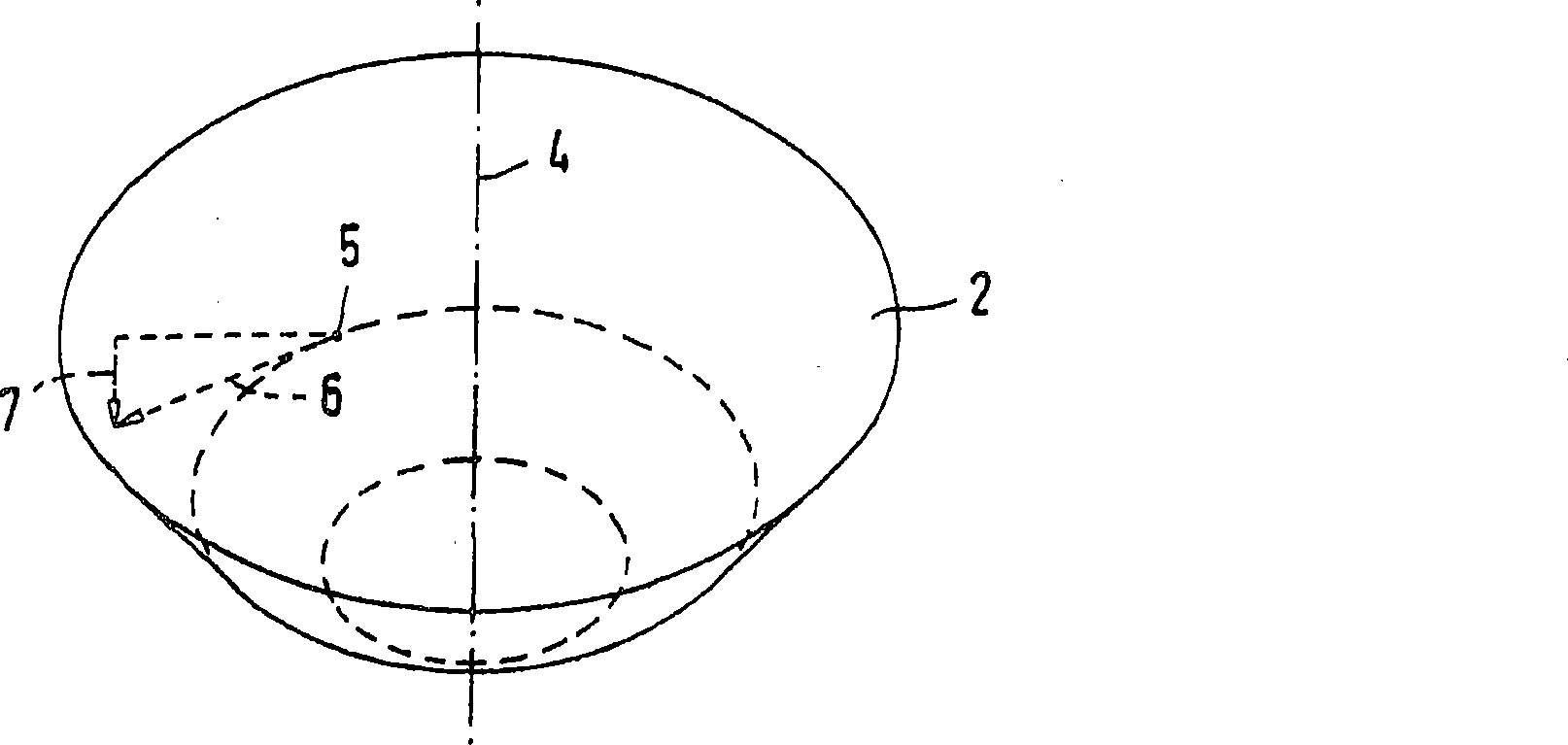

[0022] figure 1 The cross-section of the rolling stock 1 is shown in front view. The rolling stock 1 shown in the figure is a solid rod. However, the rolling stock 1 can also consist of a tube or tube blank, in which an inner mold, for example a mandrel, can be located. The rolled piece 1 is processed and formed by a plurality of rolls 2 surrounding the rolled piece 1. Figures 1 to 3 Only one roll 2 is shown in each case. Each roll 2 orbits around the longitudinal axis 3 of the rolled piece in a planetary manner, and the longitudinal axis 3 of the rolled piece is perpendicular to figure 1 paper extension. Here, the roll 2 rotates about its roll axis 4 and rolls on the outer surface of the rolling stock 1 . In the example shown, the roll 2 is substantially conical, but has the shape of two truncated cones with abutting outer surfaces of different slopes. The shape described can be seen particularly clearly in the side view in FIG. 2 , which also shows that the roll axis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com