Die cutting device for soft metal film

A soft film, die-cutting technology, applied in metal processing and other directions, can solve the problems of shortening the service life of the mold, low production efficiency, waste of resources, etc., to achieve the effect of convenient storage, reduced manual use, and not easy to be polluted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

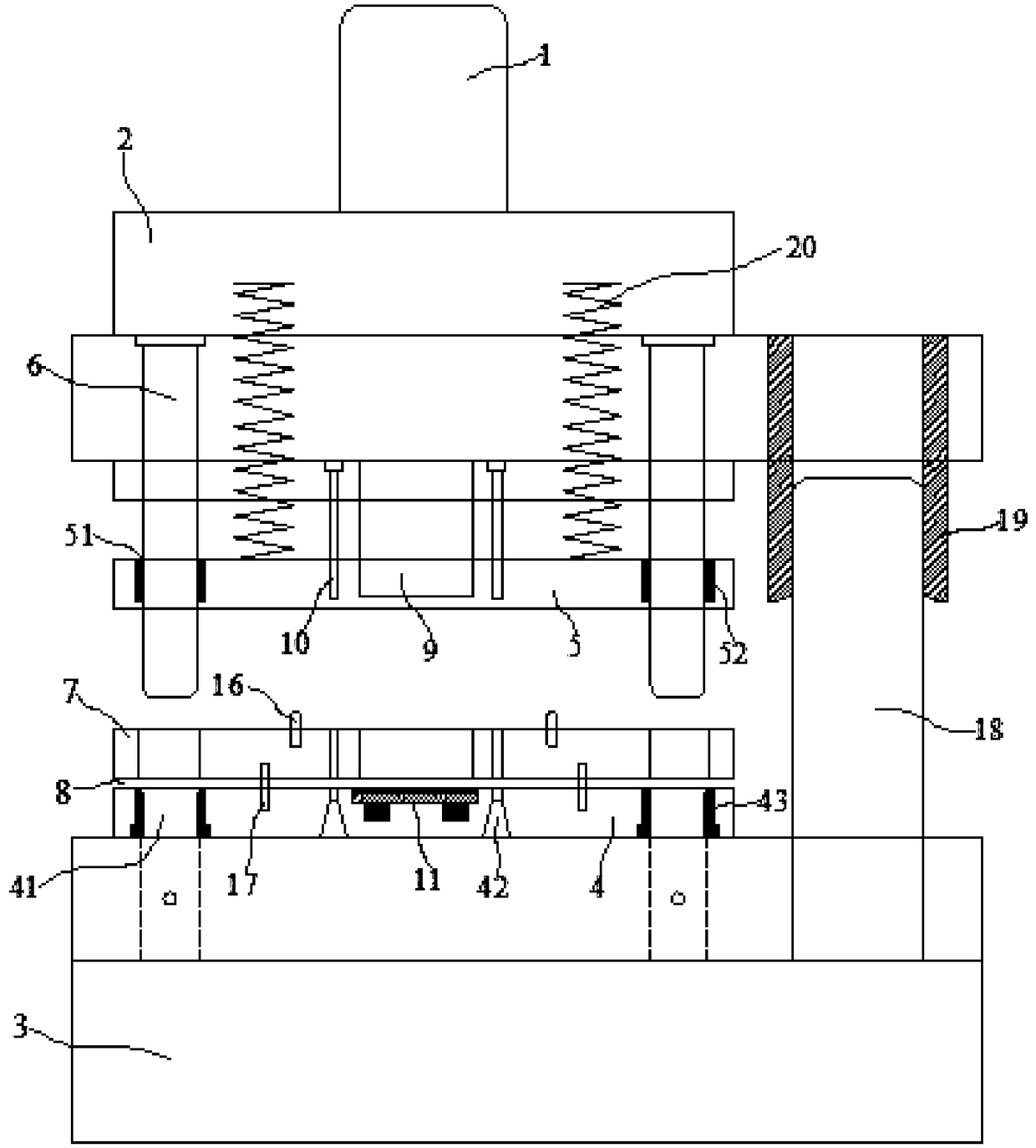

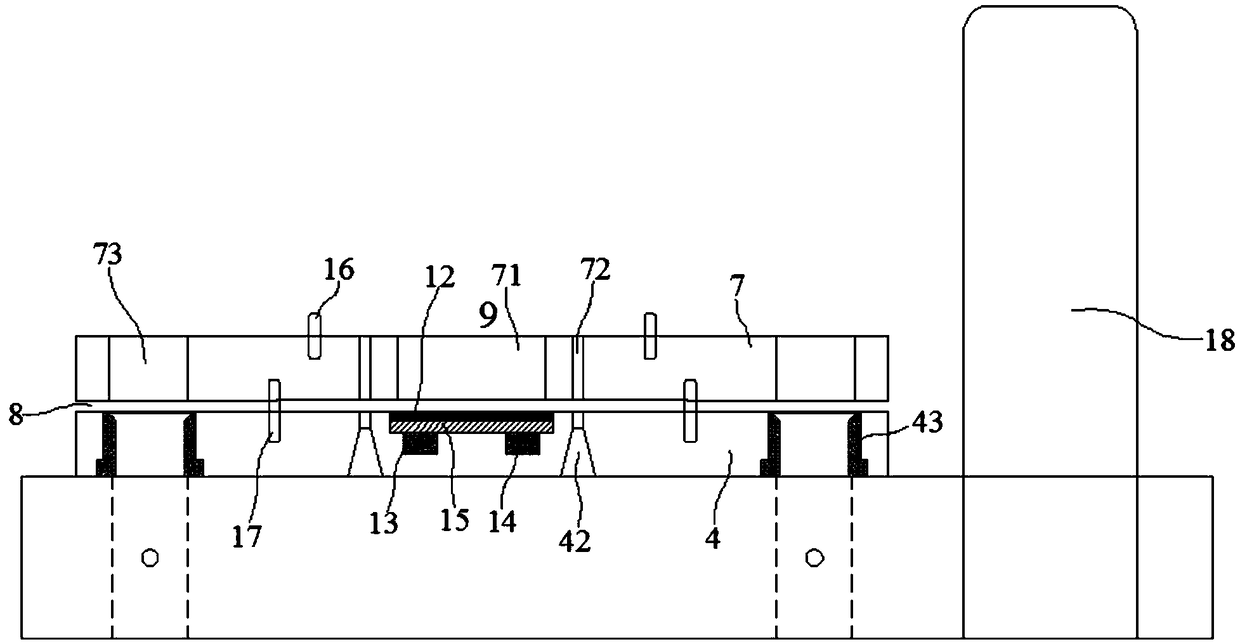

[0024] Embodiment 1: A kind of die-cutting device that is used for metal soft film, comprises upper mold handle 1, upper formwork 2 and the lower formwork 4 that is installed on the base 3, and described upper formwork 2 is installed on the lower part of upper mold handle 1 On the surface, an upper platen 5 is located below the upper formwork 2, at least two first guide posts 6 installed on the upper formwork 2 are respectively embedded in the upper through holes 51 of the upper platen 5, and an intermediate plate 7 is located above the lower formwork 4. Between the plate 7 and the lower template 4, there is a gap 8 for micro-mucosa embedding, a punch 9 and a punch needle 10 are respectively installed on the upper template 2, and a punch for the punch 9 to be embedded is arranged on the middle plate 7. Head through hole 71, pin hole 72 for inserting punching needle 10 and middle through hole 73 for inserting first guide post 6;

[0025] The middle plate 7 is located on both si...

Embodiment 2

[0031] Embodiment 2: A kind of die-cutting device that is used for metal soft film, comprises upper mold handle 1, upper formwork 2 and the lower formwork 4 that is installed on the base 3, and described upper formwork 2 is installed on the lower part of upper mold handle 1 On the surface, an upper platen 5 is located below the upper formwork 2, at least two first guide posts 6 installed on the upper formwork 2 are respectively embedded in the upper through holes 51 of the upper platen 5, and an intermediate plate 7 is located above the lower formwork 4. Between the plate 7 and the lower template 4, there is a gap 8 for micro-mucosa embedding, a punch 9 and a punch needle 10 are respectively installed on the upper template 2, and a punch for the punch 9 to be embedded is arranged on the middle plate 7. Head through hole 71, pin hole 72 for inserting punching needle 10 and middle through hole 73 for inserting first guide post 6;

[0032] The middle plate 7 is located on both si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com