Device for producing color master batches

A technology of color masterbatch and equipment, which is applied in the field of color masterbatch, can solve the problems of incomplete drying and achieve the effect of complete drying and increased gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

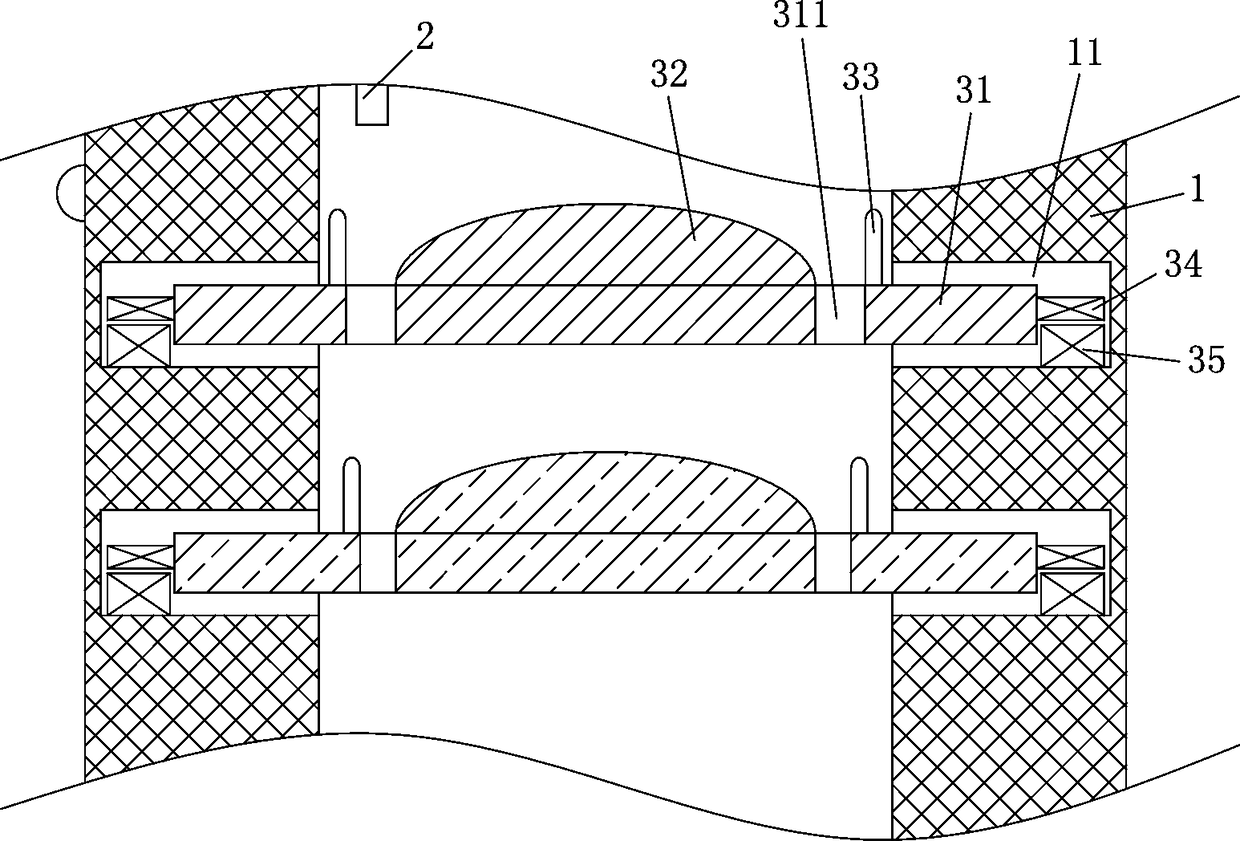

[0011] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see figure 1 , a kind of equipment for the production of color masterbatch, comprising an outer casing 1, the top of the outer casing 1 is provided with a feed inlet and an air inlet pipe 2, and the air inlet pipe 2 is connected with a heating furnace, and the outer casing 1 There are several filter components set inside.

[0012] The screening assembly includes a screening plate 31, a semicircular protrusion 32, a blocking piece 33, a magnet 34 and an electromagnet 35, and a plurality of grooves are respectively opened on the two inner walls corresponding to the outer casing 1 from top to bottom. 11. The electromagnet is provided in each groove body, and the two ends of the screening plate are respectively inserted in the corresponding groove body. At the same time, the two ends of the screening plate are respectively provided with The magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com