Intelligent classification garbage can

A dustbin, intelligent technology, applied in the direction of garbage cans, garbage collection, coinless or similar appliances, etc., can solve the problems of potential safety hazards, overflowing garbage, and inability to realize automatic fire extinguishing, so as to avoid work impact and avoid overflowing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

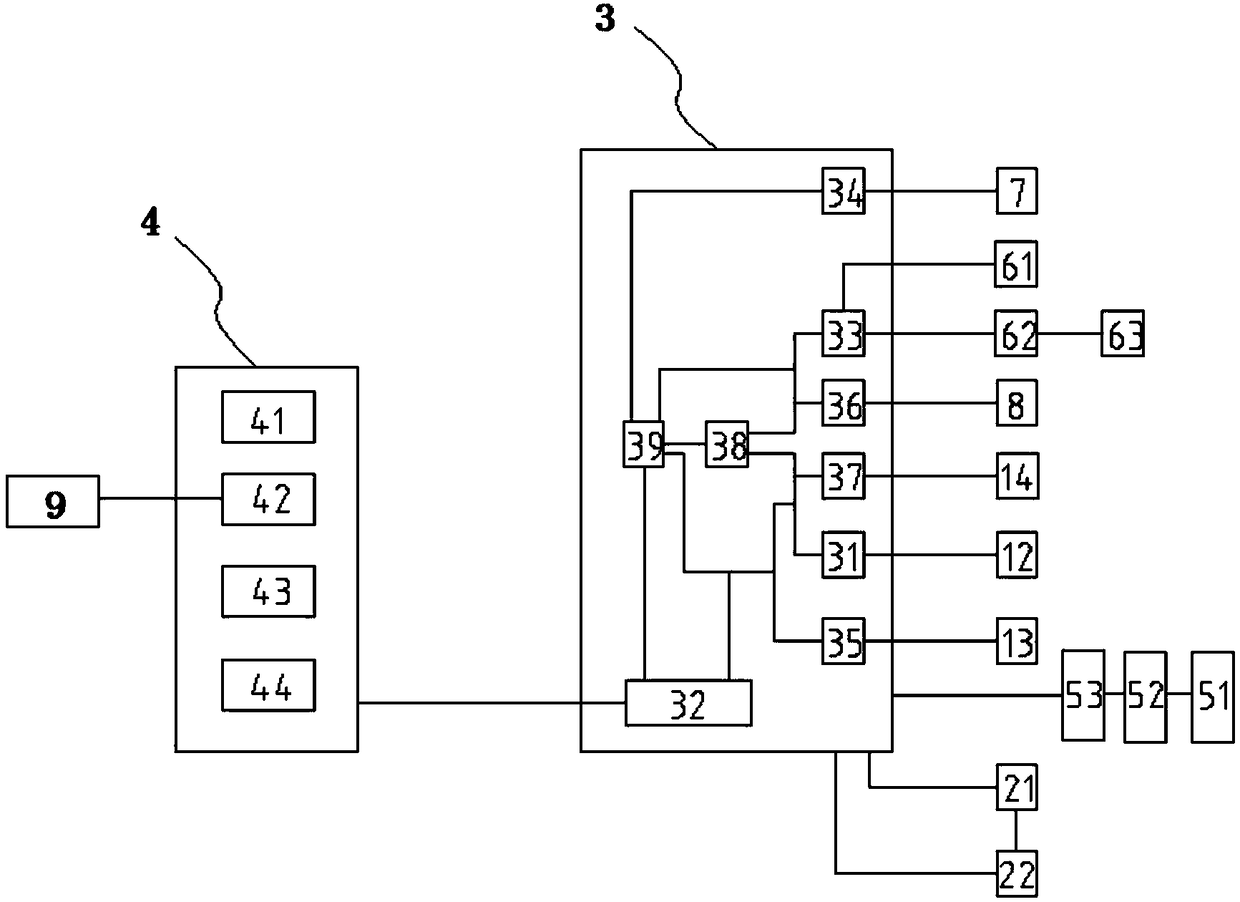

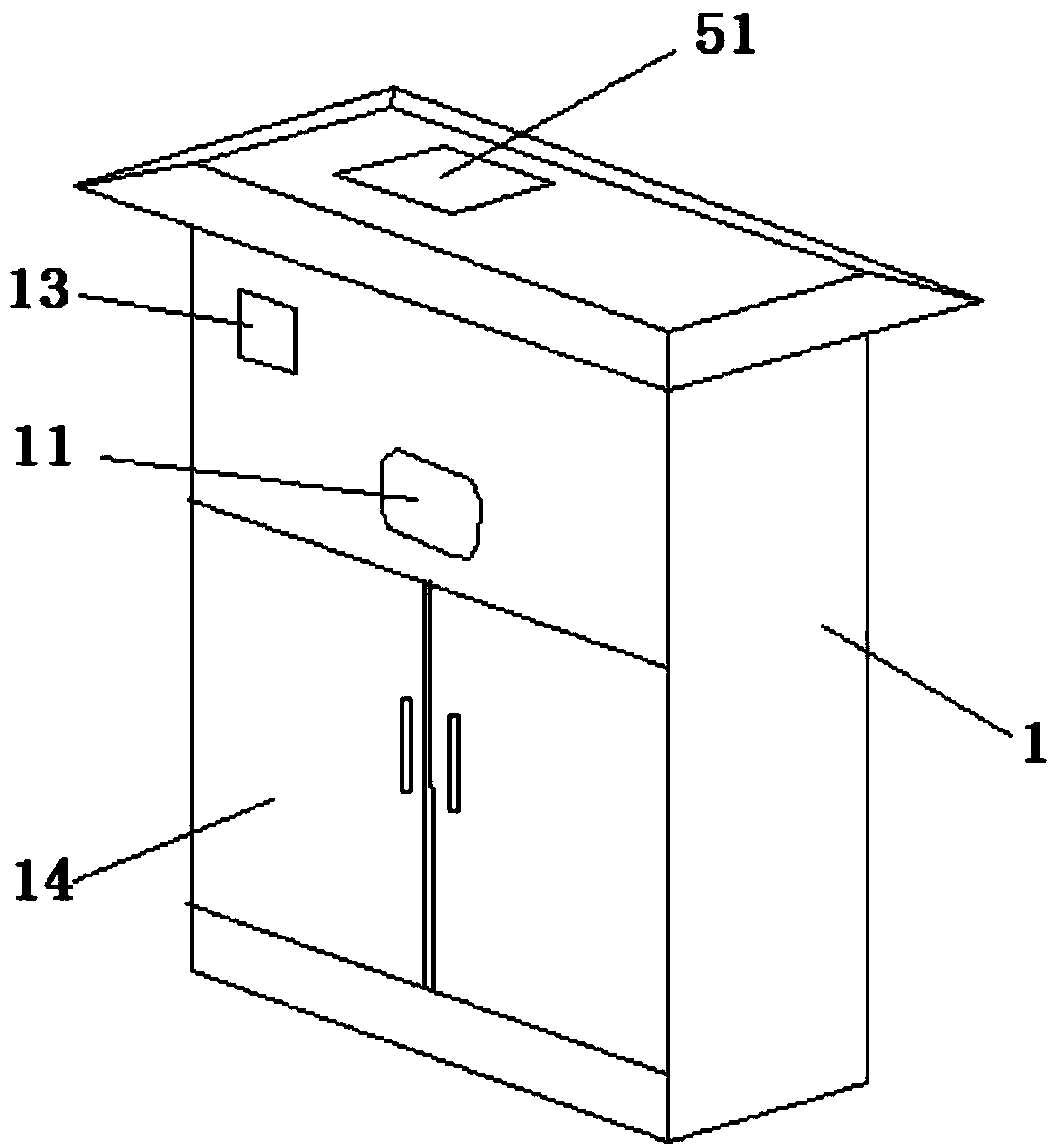

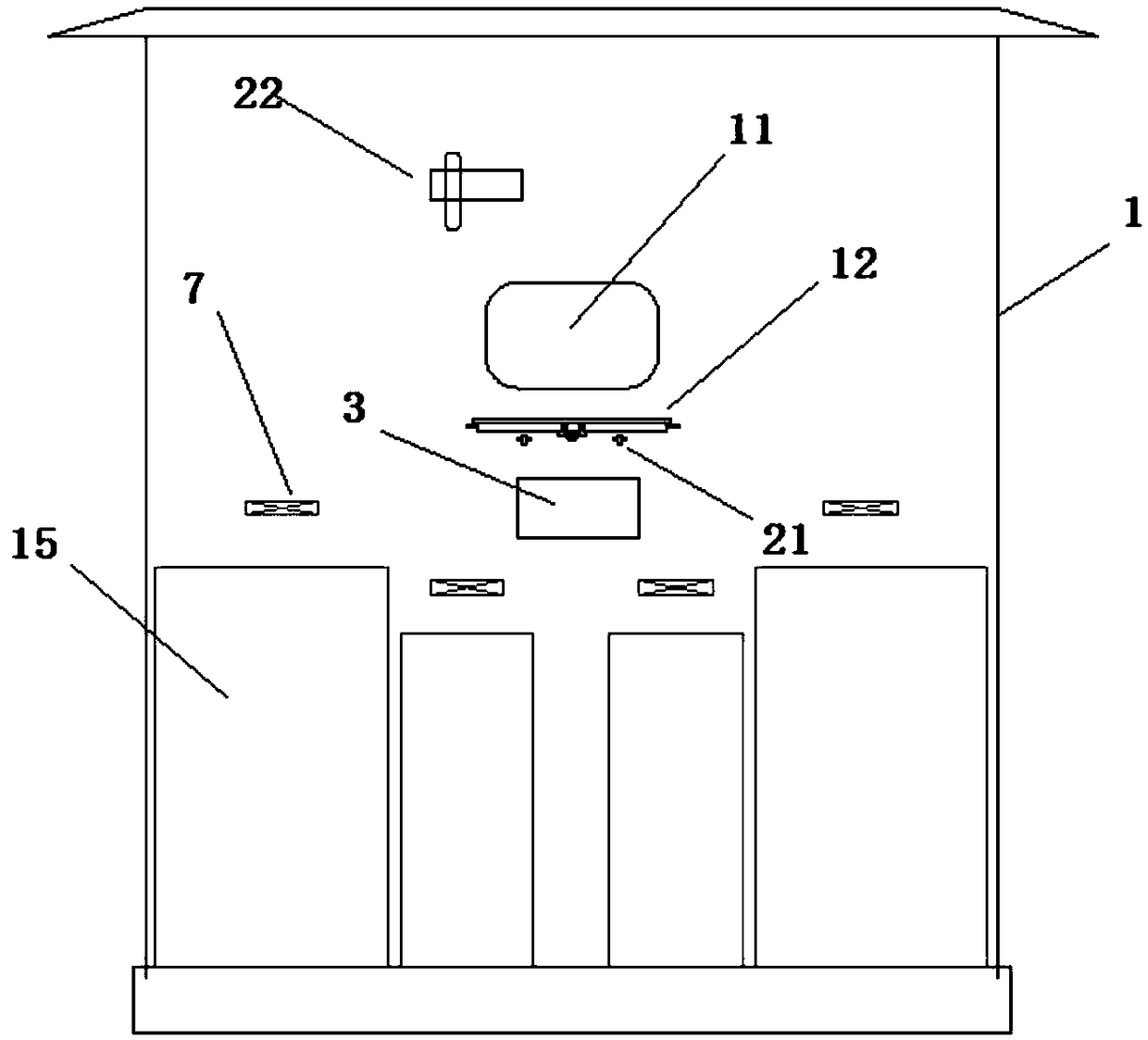

[0037] An intelligent sorting garbage bin, which includes: a box body 1, an infrared detector 21, a micro camera 22, a single-chip microcomputer 3, a cloud server 4, a solar photovoltaic panel 51, a storage battery 52, a voltage regulator 53, a temperature sensor 61, a water pump 62, Spray 63, infrared proximity switch 7, load cell 8, mobile client 9.

[0038] The box body 1 is provided with a garbage dropping port 11, a display screen 13 and an electric control recycling door 14. The garbage delivery port 11 is connected to the inside and outside of the box body 1, and the display screen 13 is connected to the single-chip microcomputer 3, and the single-chip microcomputer 3 is fixed in the box body 1. The box body 1 is also provided with a garbage sorting device 12 and a plurality of sub-boxes 15 . Wherein, the sub-boxes 15 are arranged in parallel and are located at the lower side of the garbage drop port 11; the garbage distribution device 12 includes a main motor 121, a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com