Manufacturing method for raw material twisted lines for easy-care wool

A manufacturing method and twisting technology, applied in textiles and papermaking, etc., can solve the problems of shrinkage damage, easy pilling, pilling or shrinkage, etc., and achieve the effect of excellent friction resistance and excellent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

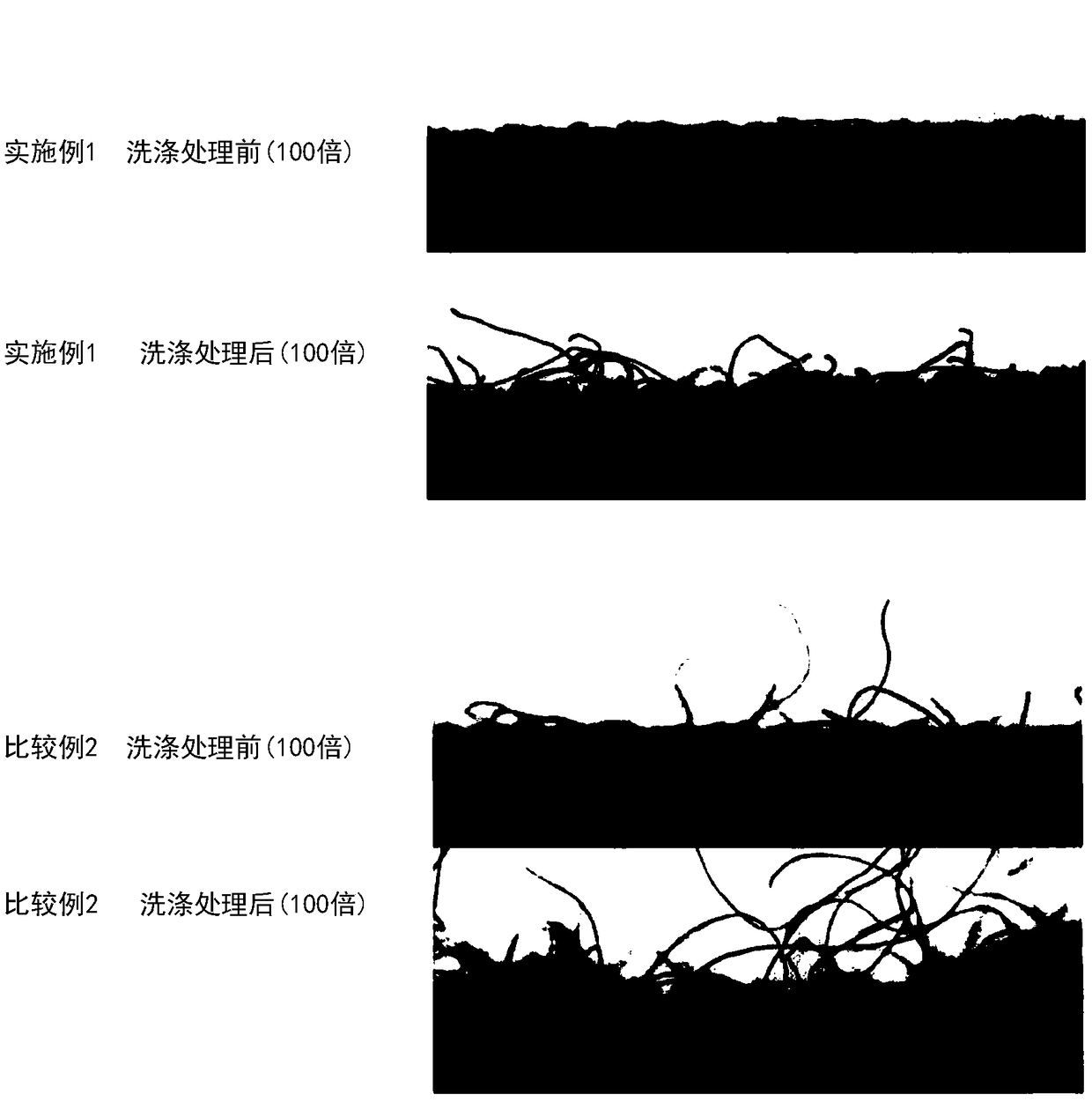

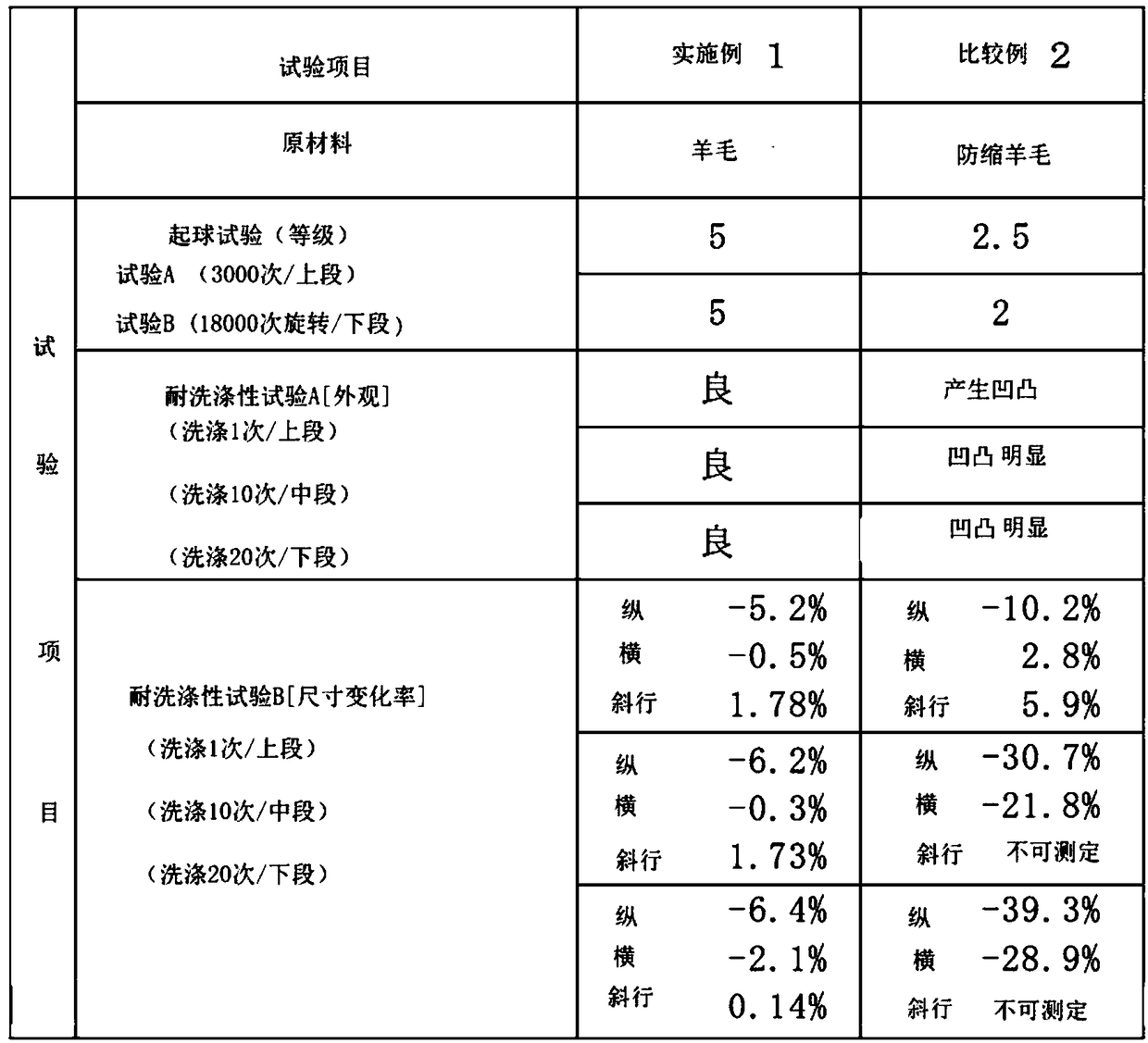

Embodiment 1

[0052] While the fluff on the fiber surface of the wool is entangled, the raw silk raw material of New Zealand wool of 17.5 μm is spun with a compact spinning machine (manufactured by Rieter Co., Ltd. (Japanese: リーターター社) to form a 1 / 60-count raw material. silk, which is wound onto the original silk with a spindle. While pulling out, drawing, and feeding the raw silk from the spindle with the raw silk, pass it through the flame part generated by propane gas from a gas burner, and burn it at about 1200±100°C to singe Singeing is carried out at a rate of 5 to 7% (the average singeing rate per unit weight of 100g is about 6%) to modify the surface of the raw silk, especially to fix the scales. One singeed raw yarn was Z-twisted at 700 times / min to form a twisted yarn. Then rub the twisted thread surface on the flannel cloth while passing the twisted thread, so that the fluff, burnt residue and soot remaining on the surface of the twisted thread are removed by twisting and rubbing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com