Novel fully-fabricated concrete profile steel frame joint and construction method thereof

A concrete and fully assembled technology, applied in building components, structural elements, piers, etc., can solve the problems of poor structural integrity and seismic performance, inconvenient construction of joints, backward technology, etc., and achieve simple and beautiful design and seismic performance. Good, improve the effect of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

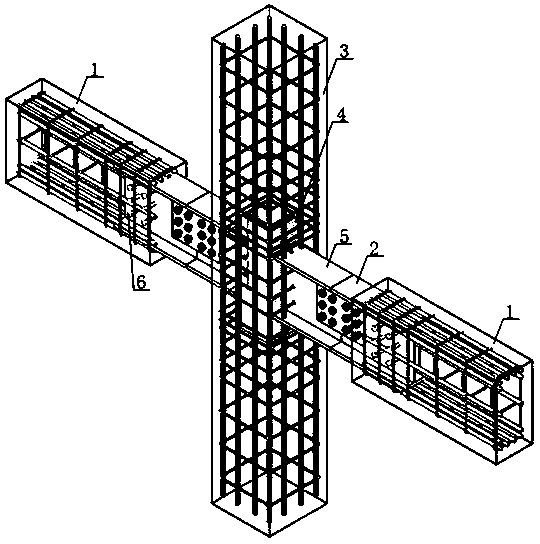

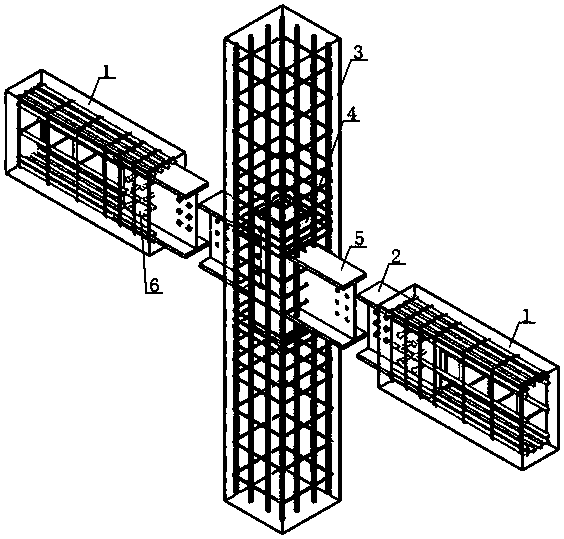

[0033] Example 1: A new fully assembled concrete steel frame node.

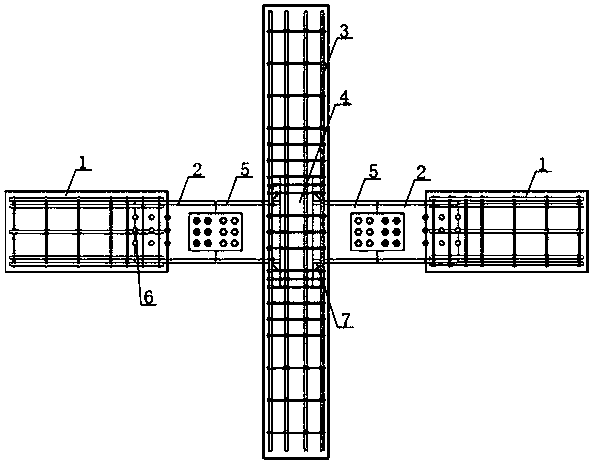

[0034] refer to Figure 1-7 , the present invention includes prefabricated concrete columns 3 arranged vertically, and rectangular vertical steel pipes 4 are pre-embedded in the node areas of the prefabricated concrete columns 3 . Both sides of the vertical steel pipe 4 are welded with horizontal H-shaped steel 5, on the web of the horizontal H-shaped steel 5 near the end of the vertical steel pipe 4, there are several vertically arranged through holes, and the two horizontal H-shaped steel 5 The through holes correspond horizontally one by one. A column stirrup 8 is pierced in two through holes on the same horizontal plane respectively to form a column stirrup net around the vertical steel pipe 4 .

[0035] The end of the horizontal H-shaped steel 5 away from the precast concrete column 3 is provided with a horizontally arranged precast concrete beam 1, and the end of the precast concrete beam 1 close to t...

Embodiment 2

[0039] Embodiment 2: The construction method of the new fully assembled concrete steel frame joint.

[0040] Such as Figure 8 As shown, the construction method of a novel fully assembled concrete steel frame node of the present invention comprises the following steps:

[0041] S1, making beam end section steel: welding stud 6 on one end web of beam end H section steel 2, and setting bolt holes for bolt connection on the other end web;

[0042] S2. Making node section steel: set bolt holes for bolt connection on one end of the horizontal H-shaped steel 5, and weld the other end with the column wall of the rectangular steel pipe 4, wherein the horizontal H-shaped steel 5 web is provided with a column hoop The through hole through which the rib 8 passes, and a vertical triangular stiffener 7 is welded between the column wall of the rectangular steel pipe 4 and the flange of the horizontal H-shaped steel 5;

[0043] S3. Binding the beam body frame: binding beam longitudinal rei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com