Lock torsional fatigue testing machine

A technology of torsional fatigue and testing machine, which is applied in the direction of strength characteristics, application of repeated force/pulsation force to test material strength, instruments, etc. It can solve the problems of wasting time, low test efficiency, and inability to detect multiple locks at the same time, and achieve enhanced Accuracy, the effect of ensuring normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

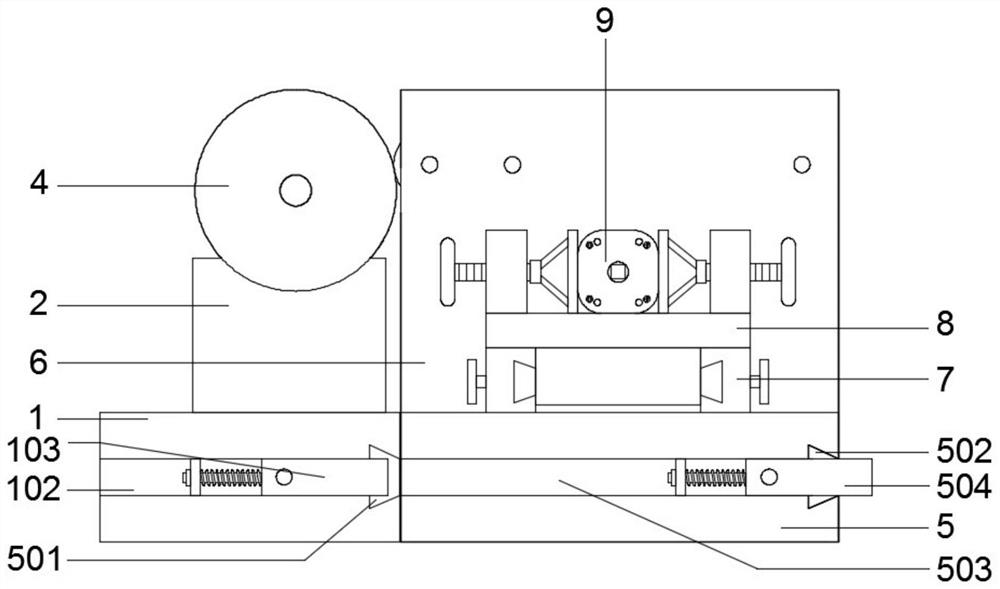

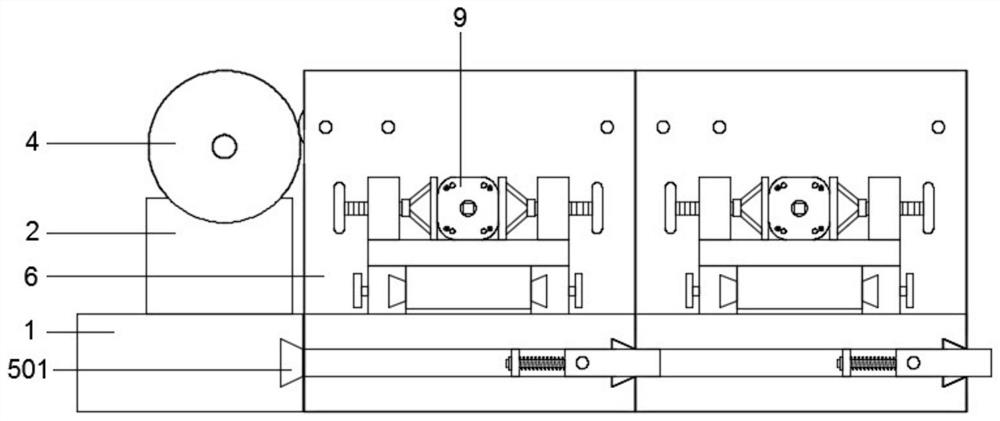

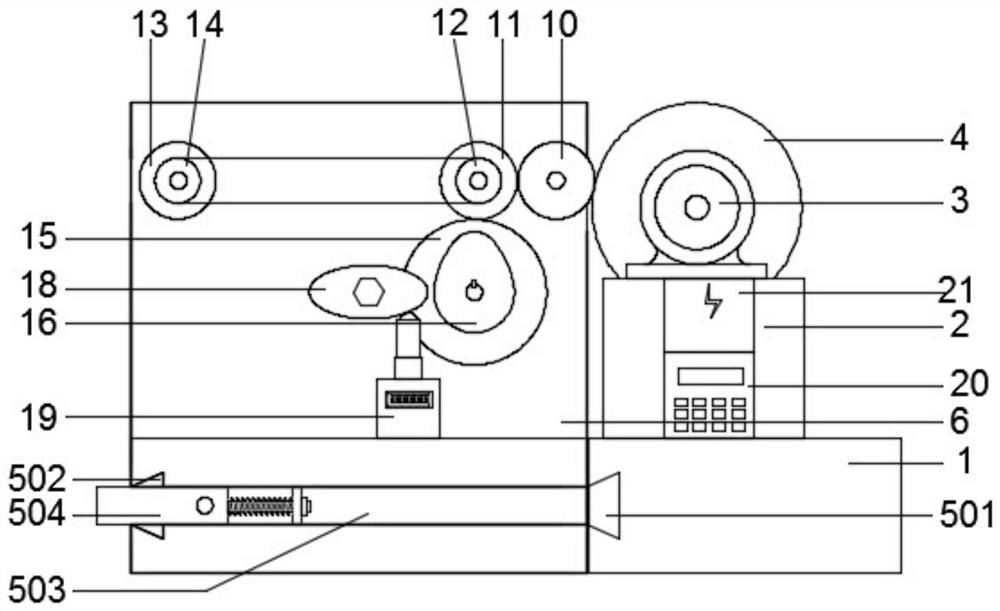

[0033] as attached figure 1 to attach Figure 8 Shown:

[0034]The invention provides a lock torsion fatigue testing machine, including: a rectangular seat A1, a trapezoidal groove A101, a rectangular groove A102, an elastic card A103, a motor seat 2, a motor 3, a gear A4, a rectangular seat B5, a trapezoidal clamping iron 501, and a trapezoidal groove B502, rectangular groove B503, elastic card B504, rectangular plate 6, sliding track 7, fixture structure 8, lock body body 9, gear B10, gear C11, pulley A12, gear D13, pulley B14, gear E15, cam 16, Cylindrical shaft 17, toggle plate 18, press counter 19, rolling ball 1901, governor 20, power control box 21 and main body of the detection structure; a trapezoidal groove A101 is opened on the right end of the rectangular seat A1, and the front end of the rectangular seat A1 A rectangular groove A102 is provided on the rear end surface, and an elastic card A103 is arranged in each rectangular groove A102; a motor seat 2 is welde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com