Obliquely-plugged umbilical electrical connection structure

An electrical connection structure, oblique insertion technology, applied in the direction of connection, components and circuits of the connection device, can solve the problems of high use cost, complexity, increase missile flight resistance, etc., and achieve low requirements, avoid impact, and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

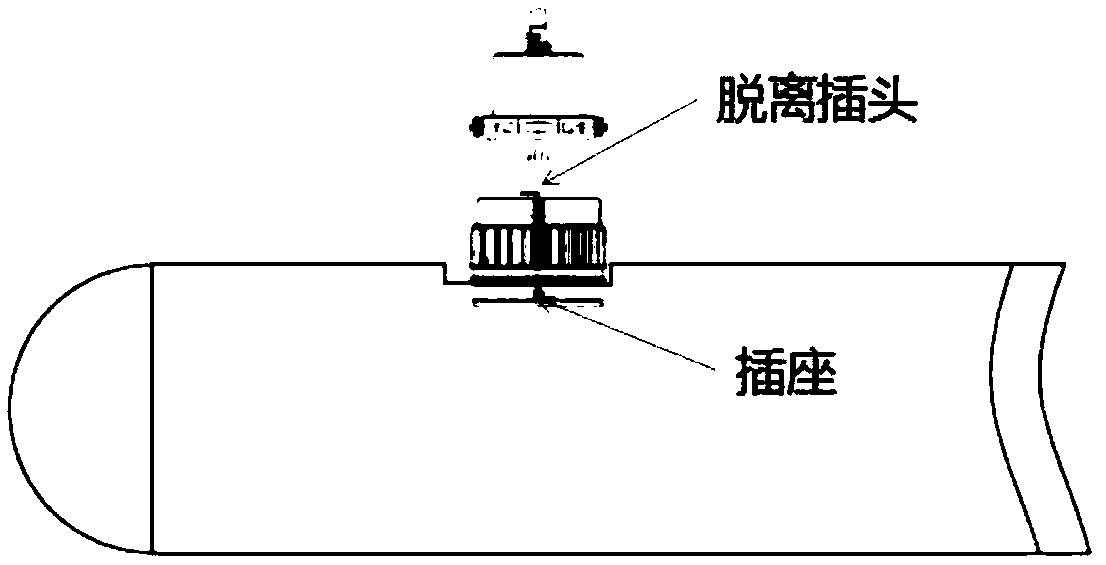

[0023] Figure 4 Shown is a schematic diagram of the oblique plug-in type drop-off electrical connection structure, such as Figure 4 As shown, the inclined plug-in type falling off electrical connection structure includes: a socket slot is provided within the envelope of the shell of the missile 4, the socket slot is arranged obliquely from the direction of the missile head to the outside, the socket 1 is arranged inside the socket slot, and the socket 1 faces The outer side of the missile is installed at a certain angle, and is located in the outer envelope of the missile 4 shell.

[0024] Such as Figure 4 As shown, after the unplugging position is determined according to the overall design constraints, a connecto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com