Positioning fixture

A technology for positioning fixtures and fixtures, which is applied in the field of machinery, can solve the problems of cumbersome use, increased labor costs, and low production efficiency, and achieve the effects of simple and reasonable overall structure design, simple and exquisite structure, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further explained below in conjunction with the accompanying drawings and embodiments.

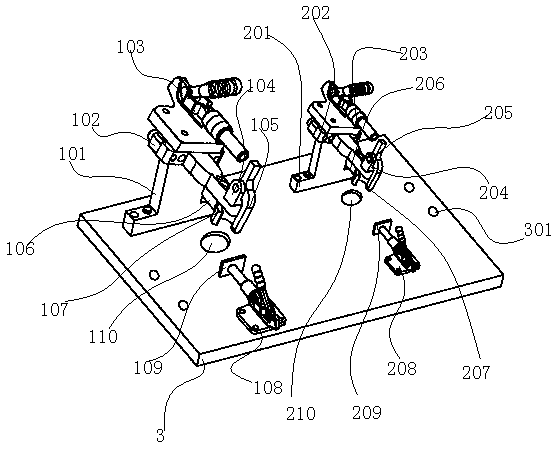

[0017] Such as figure 1 Shown, a kind of positioning jig comprises positioning base 3, and the first positioning unit and the second positioning unit that are located on positioning base 3; The first positioning unit comprises the first clamping unit and the first support unit; The first clamping The unit includes a first inverted T-shaped support 101, a first movable platform 102 and a first clamping fixture 103 adapted to the first movable platform 102; one end of the first movable platform 102 is adapted to the first clamping fixture 103 The other end of the first movable table 102 is provided with a first support base 104 and a first movable jaw 105 located on the first support base 104; a first fixed frame 106 is provided on the first inverted T-shaped support 101, and A fixed bracket 106 is provided with a first arc-shaped fixed claw 107; the fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com