Hybrid Nonwoven Composite Parts

A composite part, composite fiber technology, used in the field of thermoforming parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0068] Clause 1. A method of forming a composite part, the method comprising:

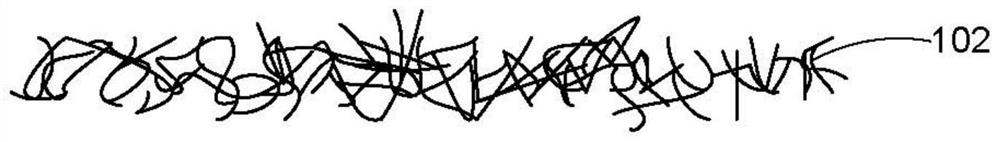

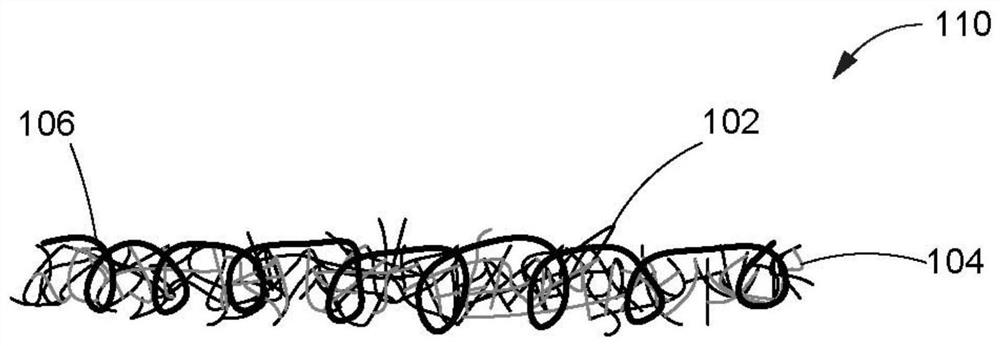

[0069] heating an unconsolidated mat comprising a first thermoplastic material, a second thermoplastic material and reinforcing fibers to a first temperature, wherein the first thermoplastic material comprises a first melting temperature, wherein:

[0070] the second thermoplastic material includes a second melting temperature greater than the first melting temperature; and

[0071] a first temperature greater than said second melting temperature;

[0072] When the unconsolidated mat is heated, the unconsolidated mat is compressed into a composite fiber reinforced consolidated sheet;

[0073] reheating the composite fiber reinforced consolidated sheet to a second temperature, wherein the second temperature is greater than the first melting temperature and less than the second melting temperature; and

[0074] When the composite fiber reinforced consolidated sheet is reheated, the composite fiber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com