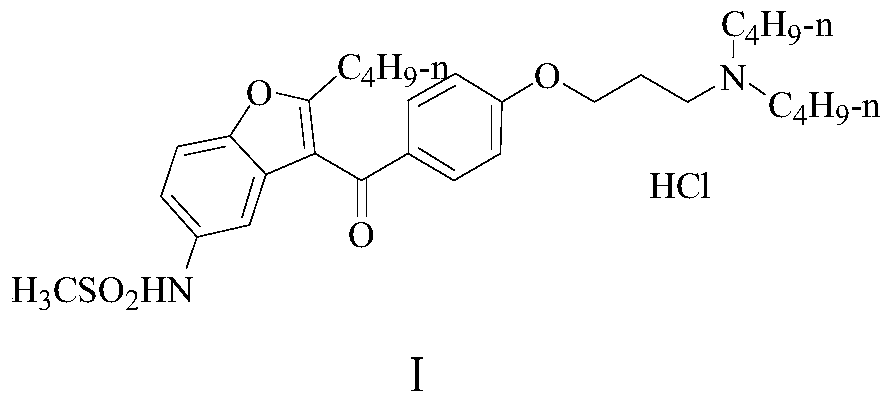

A kind of preparation method of dronedarone hydrochloride

A technology of dronedarone hydrochloride and hydrochloric acid, applied in the field of pharmaceutical synthesis, can solve problems such as difficulty in large-scale industrial production, increase in production cost, etc., and achieve the effects of less product impurities, high liquid phase purity, and fewer operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

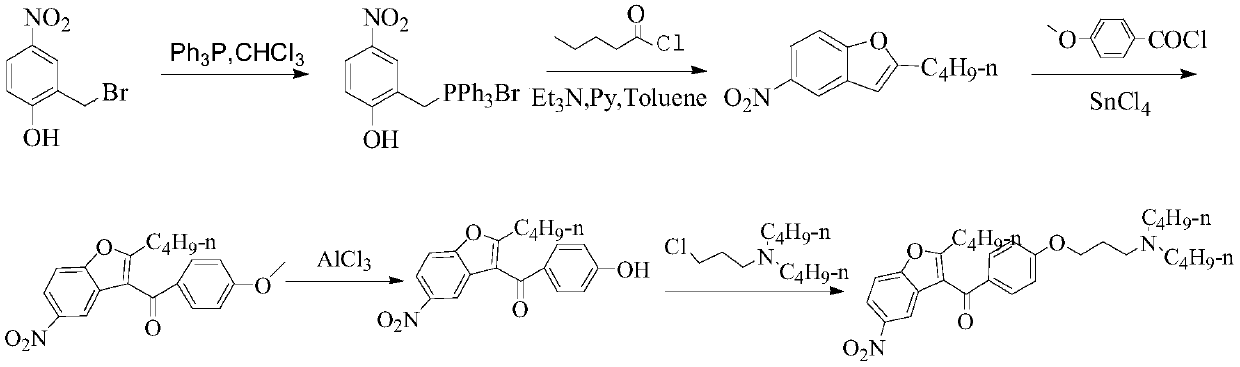

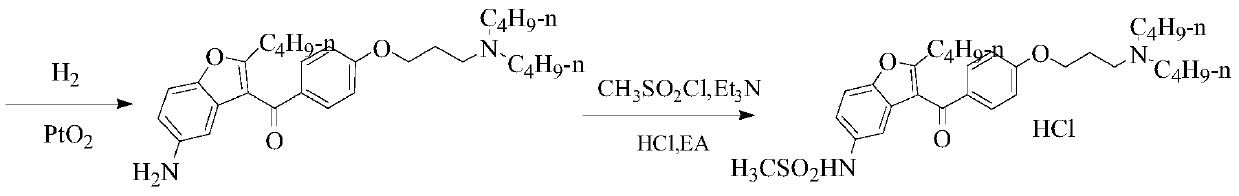

Method used

Image

Examples

Embodiment 1

[0071] A preparation method of dronedarone hydrochloride (I), comprising the following steps:

[0072] Add 1500 g of 1,2-dichloroethane, 112.0 g (1.0 mol) of 1,4-cyclohexanedione, and 3.0 g of 30% hydrochloric acid aqueous solution into a 5-liter four-neck flask, cool and keep the internal temperature at 10-15°C In between, 156.0 g (2.2 mol) of chlorine gas was slowly introduced, and the reaction was stirred at 15-25° C. for 3 h until the reaction was complete. Then nitrogen was bubbled for 2 hours to blow off the generated hydrogen chloride and excess chlorine. Thereafter, 390 grams (1.0 mol) of 1-[4-(3-dibutylamino-propoxy)-phenyl]-heptane-1,3-dione (VI) was added to the resulting reaction liquid, 152 gram of potassium carbonate, stirred and reacted at 55-60°C for 5 hours, cooled to 20°C, filtered, layered, added 30 grams of 10% hydrochloric acid aqueous solution to the gained organic layer, stirred and reacted at 40-50°C for 4 hours, divided layer, the aqueous layer was e...

Embodiment 2

[0078] A preparation method of dronedarone hydrochloride (I), comprising the following steps:

[0079] Add 1500 grams of 1,2-dichloroethane, 112.0 grams (1.0mol) of 1,4-cyclohexanedione, 5.0 grams of 40% hydrobromic acid aqueous solution to a 5-liter four-neck flask, cool, and keep the inner temperature at 10- 322.0 g (2.0 mol) of liquid bromine was slowly added dropwise at 15°C, and the reaction was stirred at 15-25°C for 2 hours until the reaction was complete. Then nitrogen gas was bubbled for 2 hours to blow off the generated hydrogen bromide gas. Thereafter, 390 grams (1.0 mol) of 1-[4-(3-dibutylamino-propoxy)-phenyl]-heptane-1,3-dione (VI) was added to the resulting reaction liquid, 152 gram of potassium carbonate, stirred and reacted at 55-60°C for 5 hours, cooled to 20°C, filtered, layered, added 30 grams of 10% hydrochloric acid aqueous solution to the gained organic layer, stirred and reacted at 40-50°C for 4 hours, divided layer, the aqueous layer was extracted tw...

Embodiment 3

[0081] A preparation method of dronedarone hydrochloride (I), comprising the following steps:

[0082]Add 1500 grams of 1,2-dichloroethane, 112.0 grams (1.0mol) of 1,4-cyclohexanedione, and 4.0 grams of anhydrous ferric chloride to a 5-liter four-neck flask, cool and keep the inner temperature at 10- Between 15°C, 156.0 g (2.2 mol) of chlorine gas was slowly introduced, and the reaction was stirred at 15-25°C for 5 hours until the reaction was complete. Then nitrogen was bubbled for 2 hours to blow off the generated hydrogen chloride and excess chlorine. Thereafter, 390 grams (1.0 mol) of 1-[4-(3-dibutylamino-propoxy)-phenyl]-heptane-1,3-dione (VI) was added to the resulting reaction liquid, 152 gram of potassium carbonate, stirred and reacted at 55-60°C for 5 hours, cooled to 20°C, filtered, layered, added 30 grams of 10% hydrochloric acid aqueous solution to the gained organic layer, stirred and reacted at 40-50°C for 4 hours, divided layer, the aqueous layer was extracted...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chromatographic purity | aaaaa | aaaaa |

| chromatographic purity | aaaaa | aaaaa |

| chromatographic purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com