Speed detecting device and method

A technology of speed detection and detection coils, applied in speed/acceleration/shock measurement, measuring devices, linear/angular velocity measurement, etc., can solve the problems of changes in estimation results and the inability to detect the moving speed of moving objects with high precision, and achieve high precision The effect of movement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Hereinafter, one embodiment of the present disclosure will be described with reference to the drawings. In addition, in the drawings attached to the specification of this application, the scales, the aspect ratios, and the like are appropriately changed and exaggerated from the actual scales and aspect ratios for the sake of illustration and understanding.

[0051] Also, terms such as "parallel", "orthogonal", and "same", values of lengths or angles, etc. used in this specification to designate shapes or geometric conditions and their degrees are not limited to strict meanings, The range in which the same degree of functionality can be expected is also included for interpretation.

[0052]

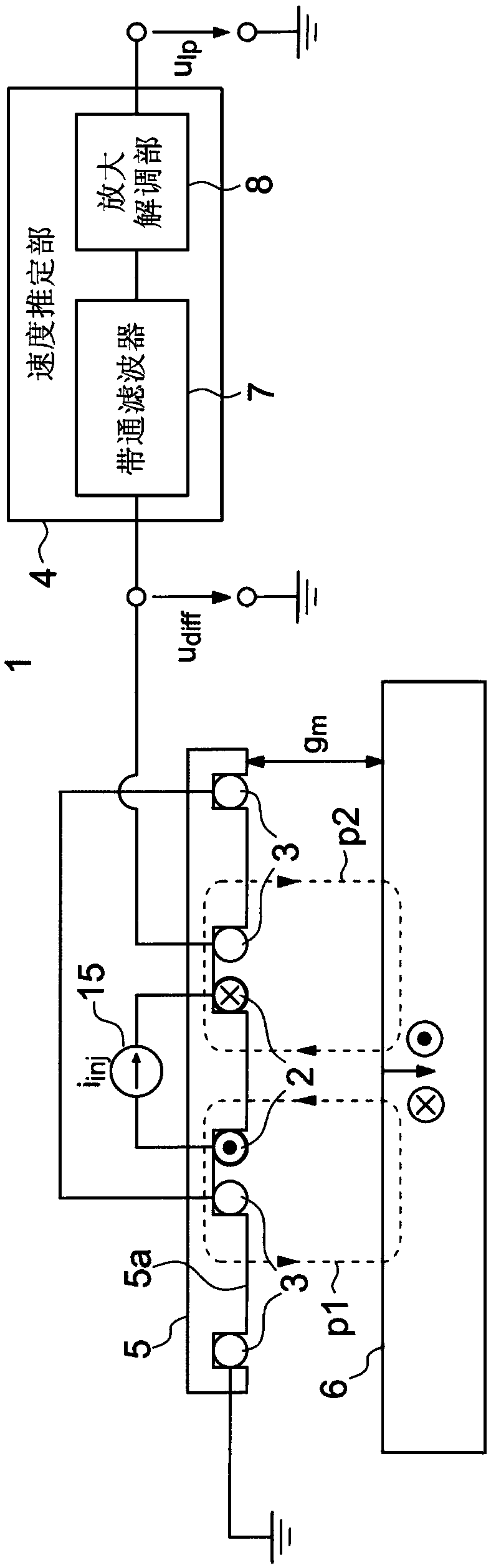

[0053] figure 1 It is a figure explaining the basic principle of the speed detection apparatus 1 of this embodiment. figure 1 The speed detection device 1 includes an exciting coil 2 , a speed estimation unit 4 and two detection coils 3 . The number of turns of the two detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com