A designing and implementation method of an elastic element module

A technology of elastic components and implementation methods, applied in computing, special data processing applications, instruments, etc., to achieve the effect of improving design efficiency, speed and efficiency, and eliminating duplication of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The method of the present invention will be further described in detail below in conjunction with the drawings and the embodiments of the present invention.

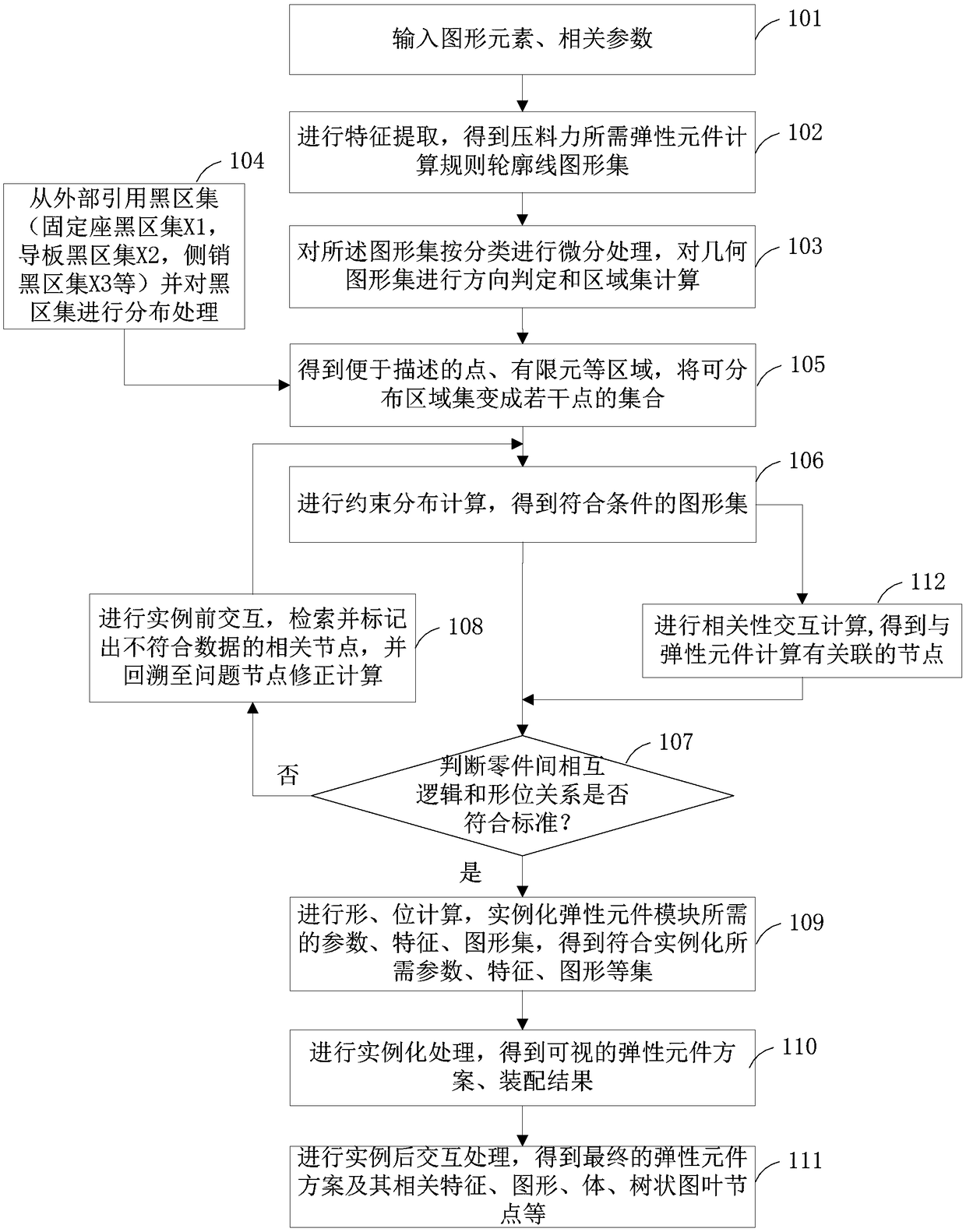

[0031] figure 1 It is a schematic flow diagram of the design and realization method of the elastic element module of the embodiment.

[0032] Such as figure 1 As shown, the design and realization method of the elastic element module mainly includes the following steps:

[0033] Step 101: Input graphic elements and related parameters. The input graphic elements and related parameters include the upper presser segmentation curve (CSUP), work profile (SW), punching set (PS), shaping set (BS), flanging set (DFS), stroke ( ST) and part material thickness (PT), etc.

[0034] Step 102: Perform feature extraction to obtain the elastic element required for the pressing force (F) to calculate a set of regular contour lines.

[0035] Here, the feature extraction process is specifically: extracting the original graphics according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com