Loss-reducing pick-up mechanism for separate harvesting of tuber crops

A technology for picking up mechanism and crops, applied in the field of agricultural machinery, can solve the problems of bending over, leaning over, fatigue in picking up work, manual picking up work, low picking up efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

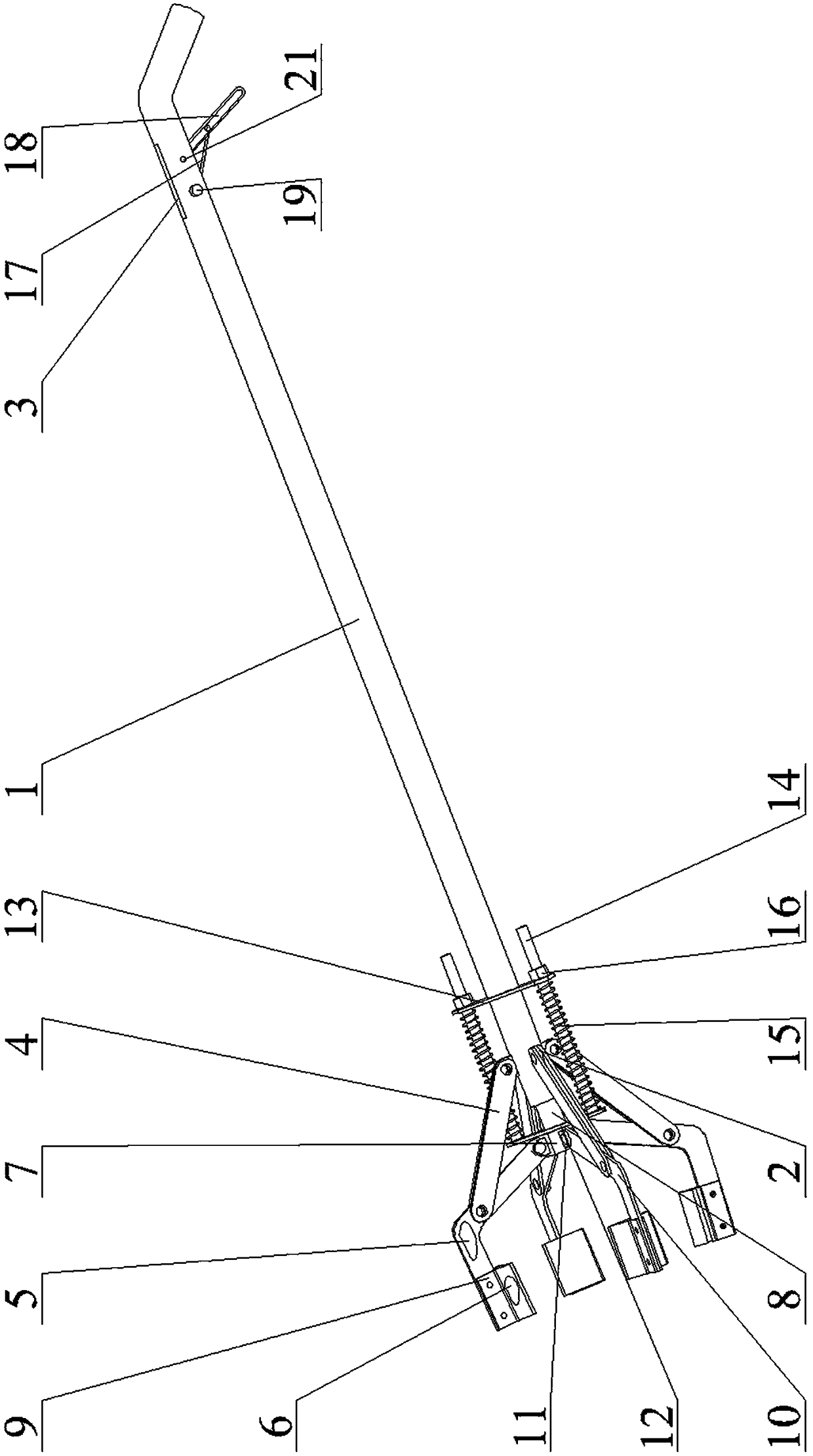

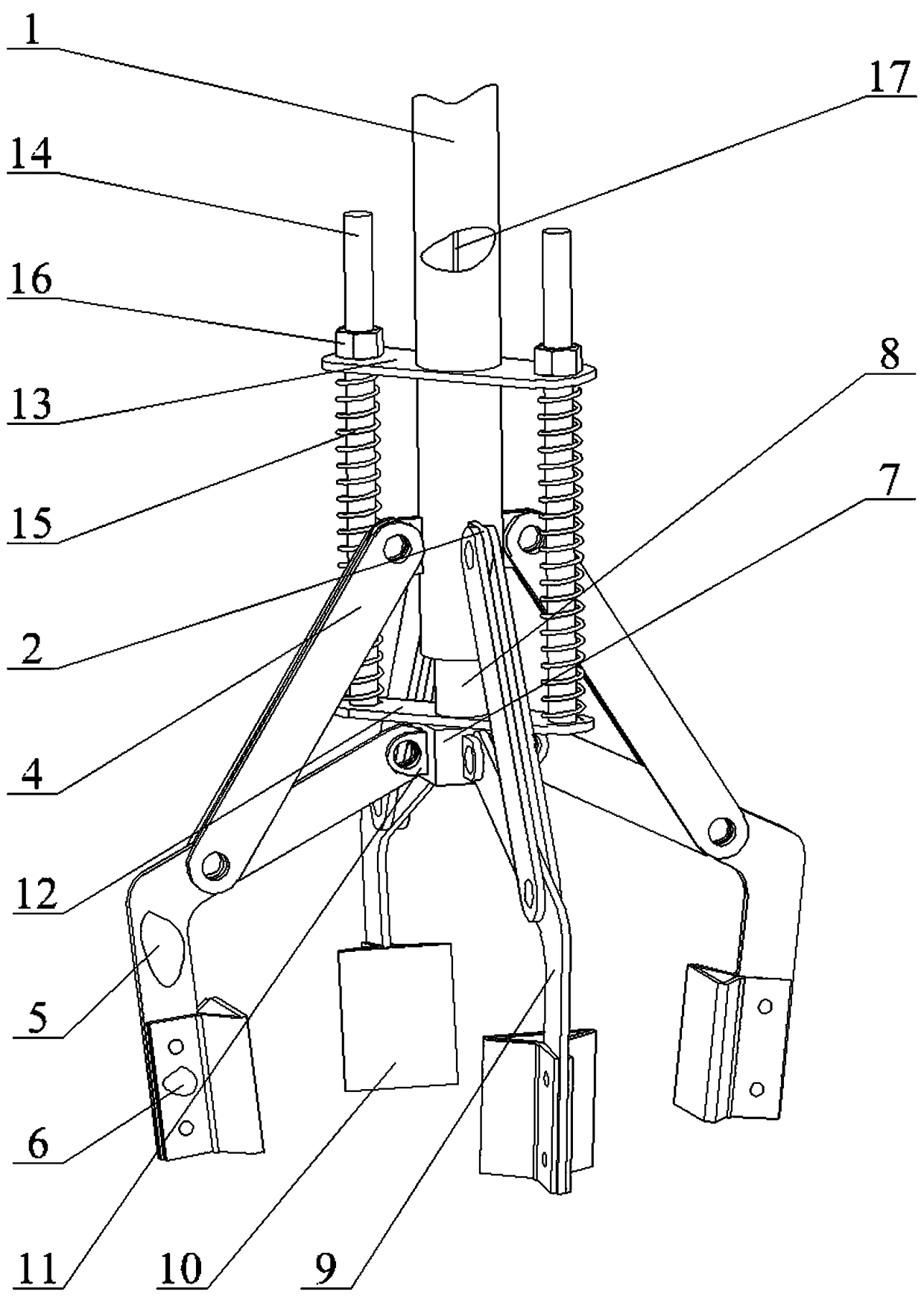

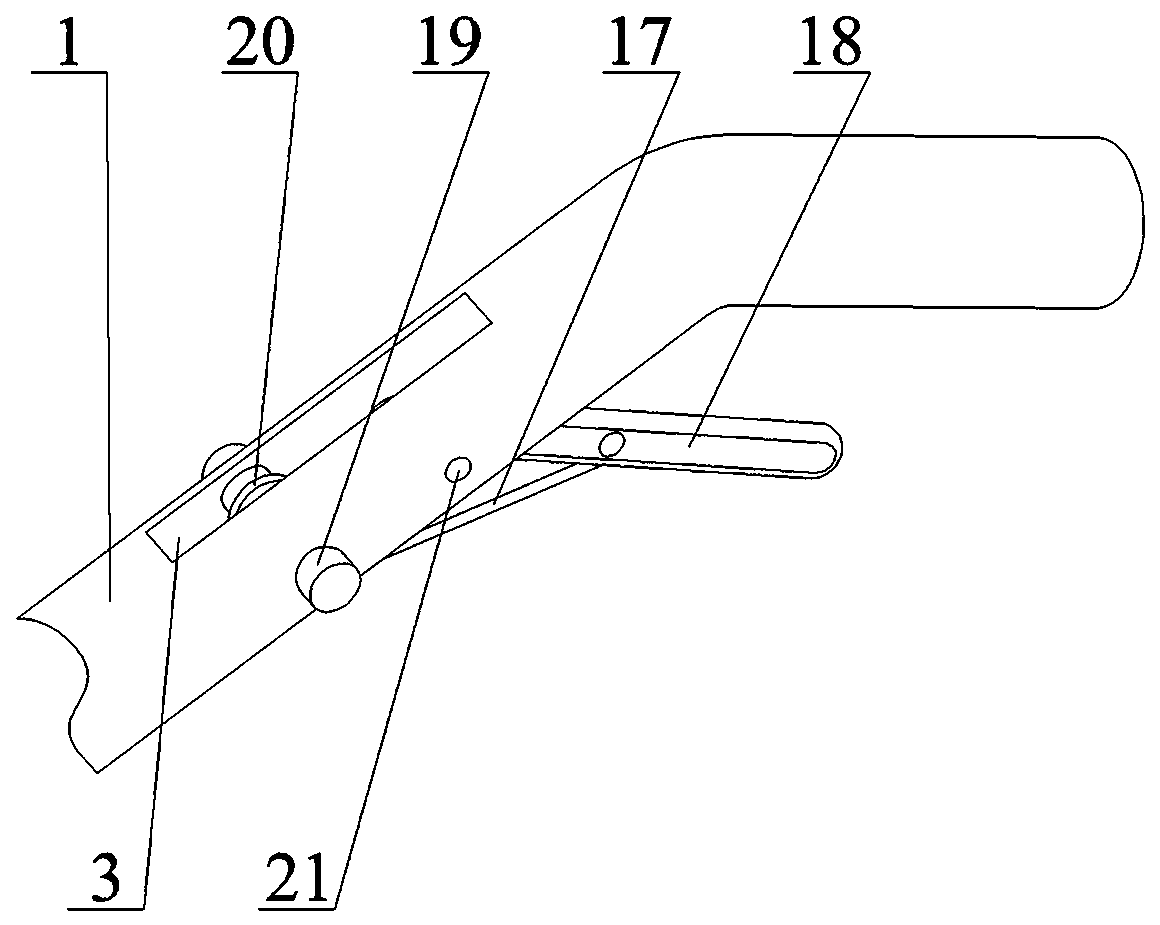

[0014] 1. Hand-held rod 2, lug Ⅰ 3, strip groove 4, movable arm 5, pick-up claw 6, fixed frame 7, connecting block 8, telescopic rod 9, elastic rubber sleeve Ⅰ 10, elastic rubber sleeve Ⅱ 11, lug Ⅱ 12, fixed plate Ⅰ 13, fixed plate Ⅱ 14, stud 15, spring 16, nut 17, elastic brace 18, adjusting plate 19, support column 20, pulley 21, support pin.

[0015] exist Figure 1~3In the shown embodiment: the upper part of the circular tubular handle bar 1 is bent at an angle of 135°, and the lower part of the handle bar 1 protrudes 4 pieces of lugs at equal intervals in the circumferential direction of the handle bar 1 at the end far away from the bending section. Ⅰ2, lugs Ⅰ2 are provided with a round hole whose axis is perpendicular to the center line of the hand-held rod 1, and the end of the hand-held rod 1 near the bending section is symmetrically provided with two length directions and the hand-held rod below the bend of the hand-held rod 1. The long slots 3 with the same length d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com