Shearing device of resin glass

A cutting device and resin glass technology, applied in metal processing and other directions, can solve the problems of complicated operation and inconvenient carrying of cutting equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

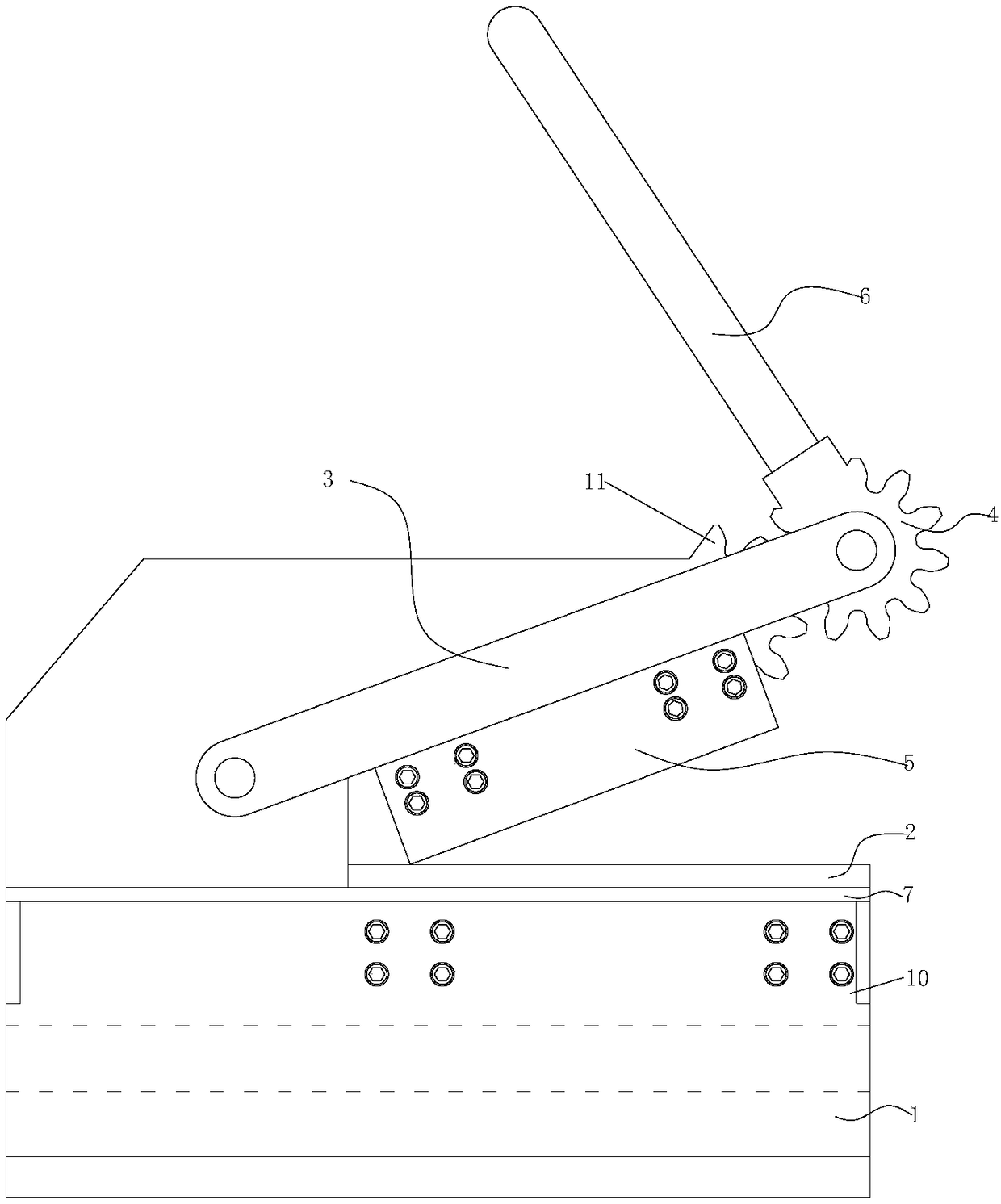

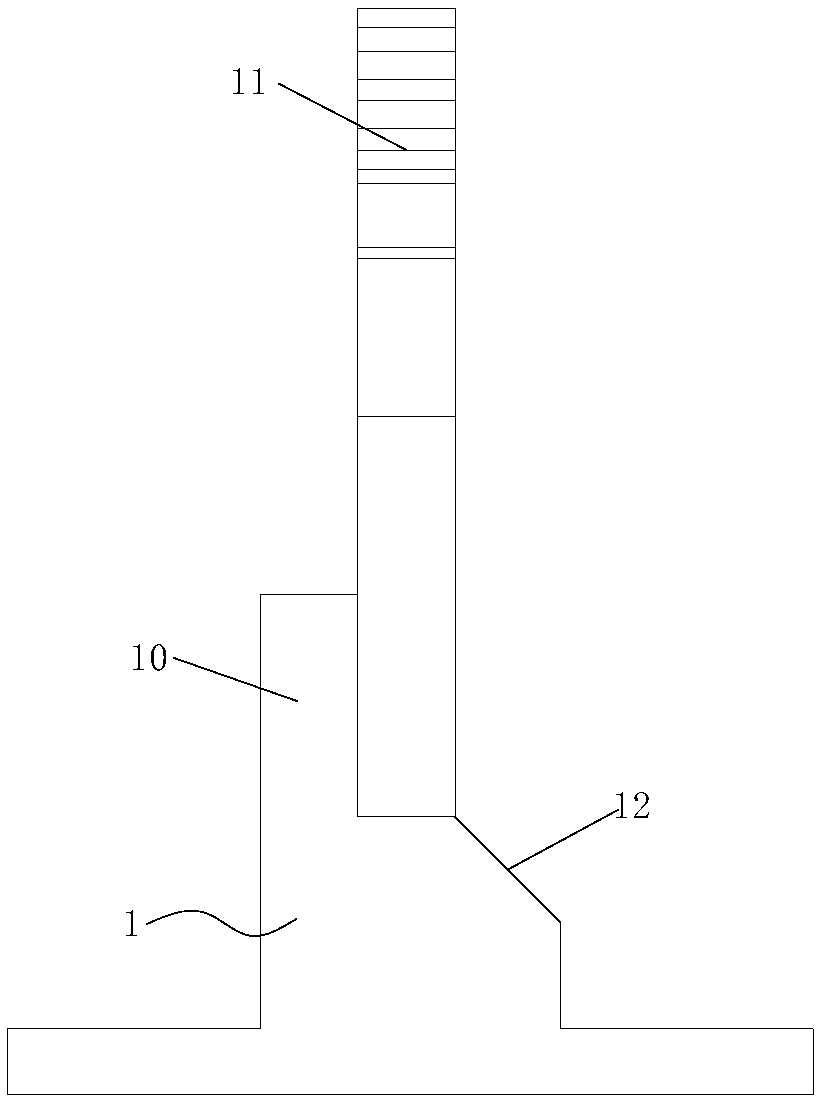

[0023] The plexiglass shearing device is small in size and easy to carry; the plexiglass is measured and cut to size, then the plexiglass is placed on the platform plate 7, and then the cutting dimension line is aligned with the edge of the lower knife plate 2, and then held by hand The wrench lever 6 rotates clockwise, because the top of the base 1 is provided with a fixed gear 11, and the gear one 4 meshes with the fixed gear 11, so the connecting rod 3 takes the upper knife plate 5 around the connecting rod 3 and the side wall of the base 1 to hinge. The axis rotates to cut the resin glass to the required size, which is convenient for cutting and easy to operate.

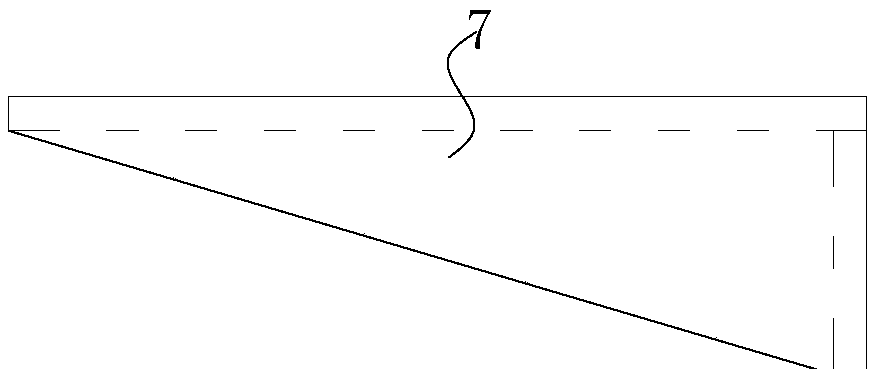

[0024] The side of the base 1 is provided with a platform plate 7 to ensure that the resin glass is placed horizontally;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com