Conveying line switch system for food processing

A food processing and conversion system technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of inconvenient operation, large area occupied by the conveyor belt, etc., and achieve the effect of good steering effect, reasonable structure and fast conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

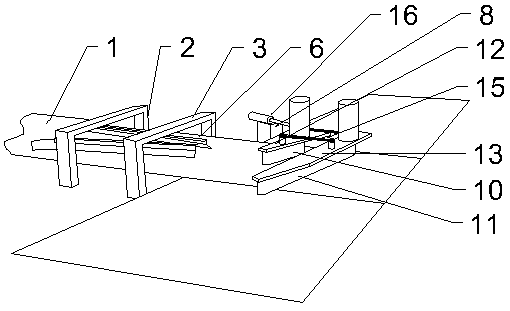

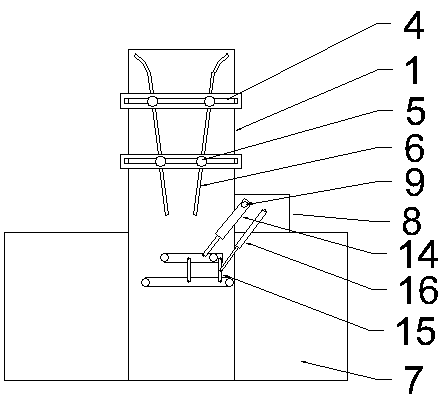

[0012] Below in conjunction with all accompanying drawings the present invention will be further described, and preferred embodiment of the present invention is: see appended figure 1 And attached figure 2 , a conveyor line conversion system for food processing described in this embodiment includes a main conveyor belt 1, a sorting conveyor belt 7 is installed at the end of the output end of the main conveyor belt 1, and fixed on both sides of the output end of the main conveyor belt 1. Support column 2, the support column 2 on each side of the main conveyor belt 1 is two, a horizontal support plate 3 is fixed between the tops of the two support columns 2, and the horizontal support plate 3 is provided with an adjustment groove 4 that penetrates up and down. There are two sets of adjusting screws 5 movable on the groove 4, and a guide baffle 6 is installed at the bottom of each set of adjusting screws 5. After installation, a trapezoidal food guide area is formed between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com