Novel hollow plastic formwork

A plastic formwork and formwork technology, applied in the field of building formwork, can solve the problems of easy water seepage, easy deformation, and poor load-bearing capacity of the formwork, and achieve the effect of avoiding movement and water seepage, eliminating influence, and improving support force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

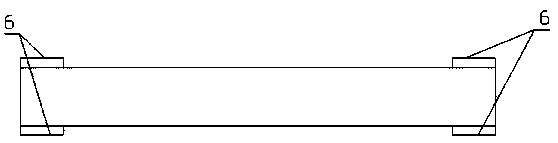

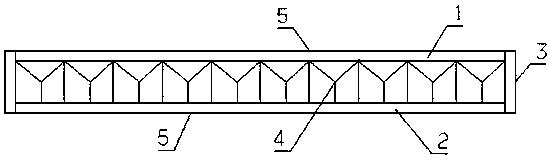

[0016] A novel hollow plastic formwork comprises an upper formwork 1, a lower formwork 2, and two side panels 3, and the combination of the upper formwork 1, the lower formwork 2 and the two side panels 3 forms a hollow cavity. The thickness of the upper template 1, the lower template 2 and the side panels 3 is 5-6mm. Several Y-shaped reinforcing ribs 4 are arranged in the hollow cavity, and the upper formwork 1, lower formwork 2, side plates 3 and Y-shaped reinforcing ribs 4 are integrally formed. The thickness of the Y-shaped reinforcing rib 4 is 1.5-2mm. The upper surface of the upper template 1 and the lower surface of the lower template 2 are provided with a coating layer 5, and the color of the coating layer 5 is white. The two ends of the coating layer 5 of the upper template 1 are provided with a symmetrical adhesive layer 6, and the two ends of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com