Device for testing transverse stiffness of corrugated pipe

A technology of lateral stiffness and testing device, which can be used in measuring devices, elastic testing, and testing of machine/structural components, etc., and can solve the problem of less introduction of lateral stiffness testing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

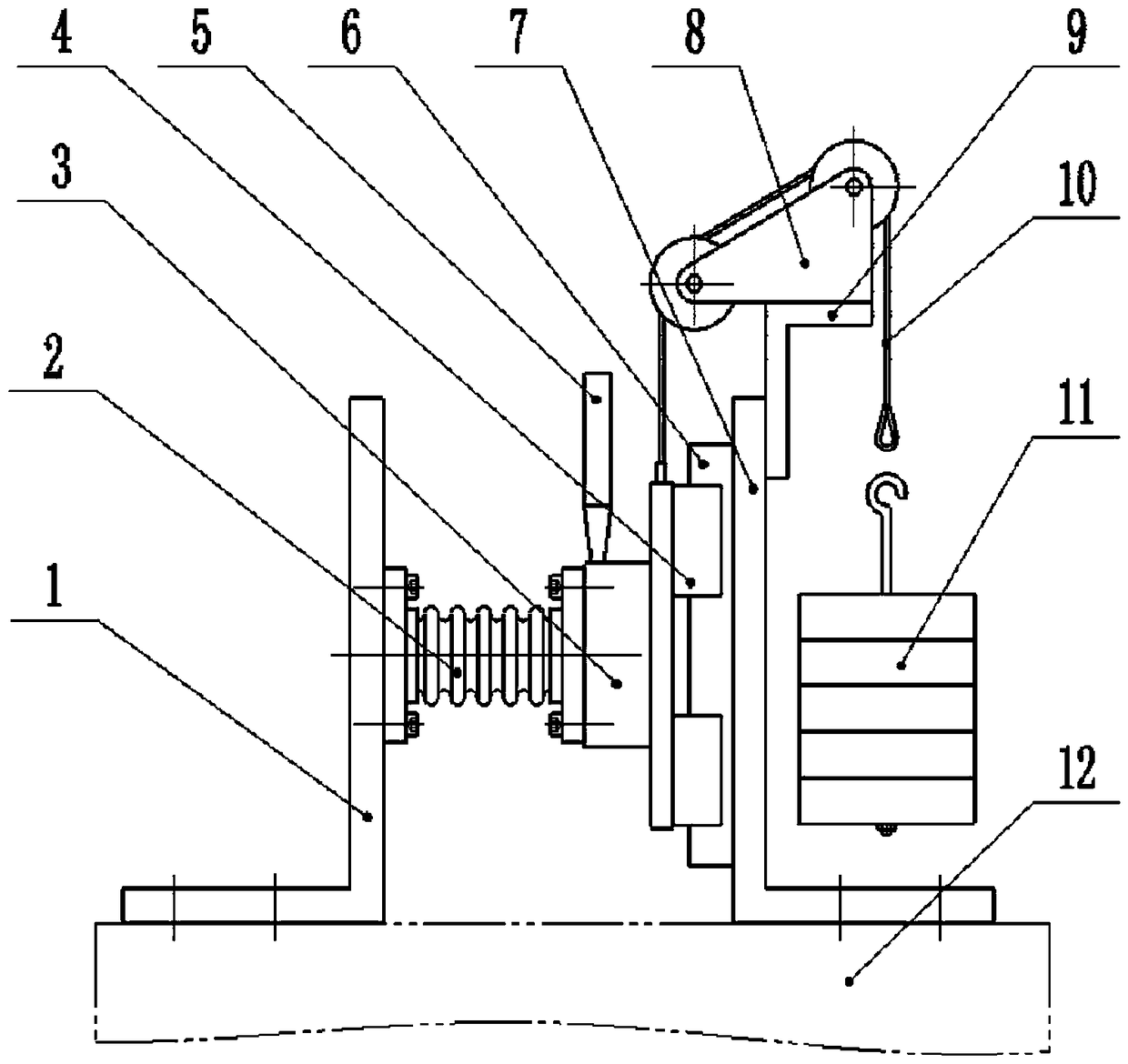

[0017] Such as figure 1 As shown, 12 in the figure is a platform, and 2 is a corrugated pipe to be tested. On the horizontal platform 12, two parallel left vertical boards 1 and right vertical boards 7 are vertically arranged. Between the plates 7, there is a bellows 2 to be tested, one end of which is fixed on the left vertical plate 1, and the other end of the bellows 2 to be tested is installed on the right vertical plate through the slider 3, the linear bearing group 4 and the slide rail 6. 7, the linear bearing group 4 can freely slide up and down with low frictional resistance along the vertical direction on the slide rail 6, and a steering bearing pulley block 8 is also fixedly arranged on the top of the right vertical plate 7 through the support angle steel 9, and the steering bearing pulley block Soft thin wire rope 10 is installed on 8, and one end of this wire rope 10 is connected with the top of linear bearing group 4, and the other end of wire rope 10 is then conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com