Fixture and bursting device for bursting test of coated fabric membrane material

A technology for coating fabrics and experimental devices, which is applied to measuring devices, analytical materials, instruments, etc., can solve the problems of high cost of bursting experimental devices and inapplicability of coated fabric membrane materials, avoiding relative slippage and improving reliability. performance and accuracy, the effect of increasing the coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and together with the embodiments of the present invention are used to explain the principle of the present invention and are not intended to limit the scope of the present invention.

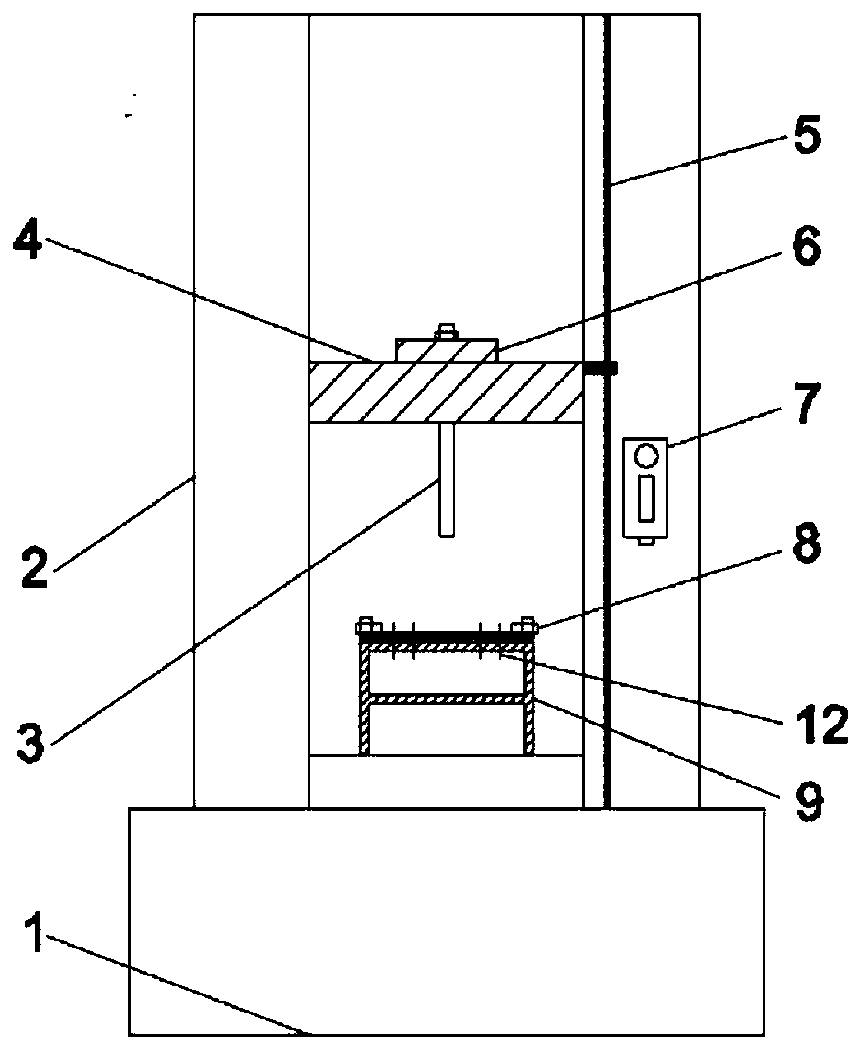

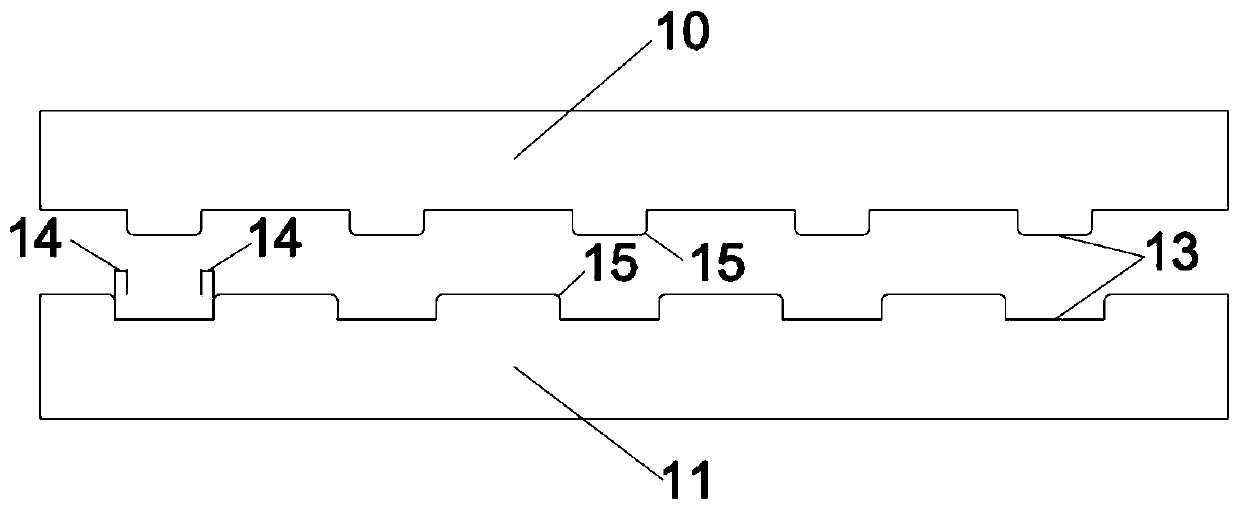

[0050] On the one hand, the present invention provides a kind of fixture that is used for the bursting test of coated fabric film material, such as image 3 As shown, it includes a first fixing part 10, a second fixing part 11, a third fixing part 12 and a clamp bracket 9; the second fixing part 11 is arranged on the clamp bracket 9 and is movably connected with the clamp bracket 9, and the first fixing part 10 is arranged above the second fixture 11, the film test piece is arranged between the first fixture 10 and the second fixture, and the third fixture 12 is arranged on the side of the fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com