A method for repairing defects and holes in three-dimensional mesh model based on characteristic lines

A technology of 3D mesh and repair method, which is applied in 3D modeling, image data processing, instruments, etc., and can solve problems such as information interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0050] A method for repairing defect holes in a three-dimensional mesh model based on feature lines, comprising the following steps:

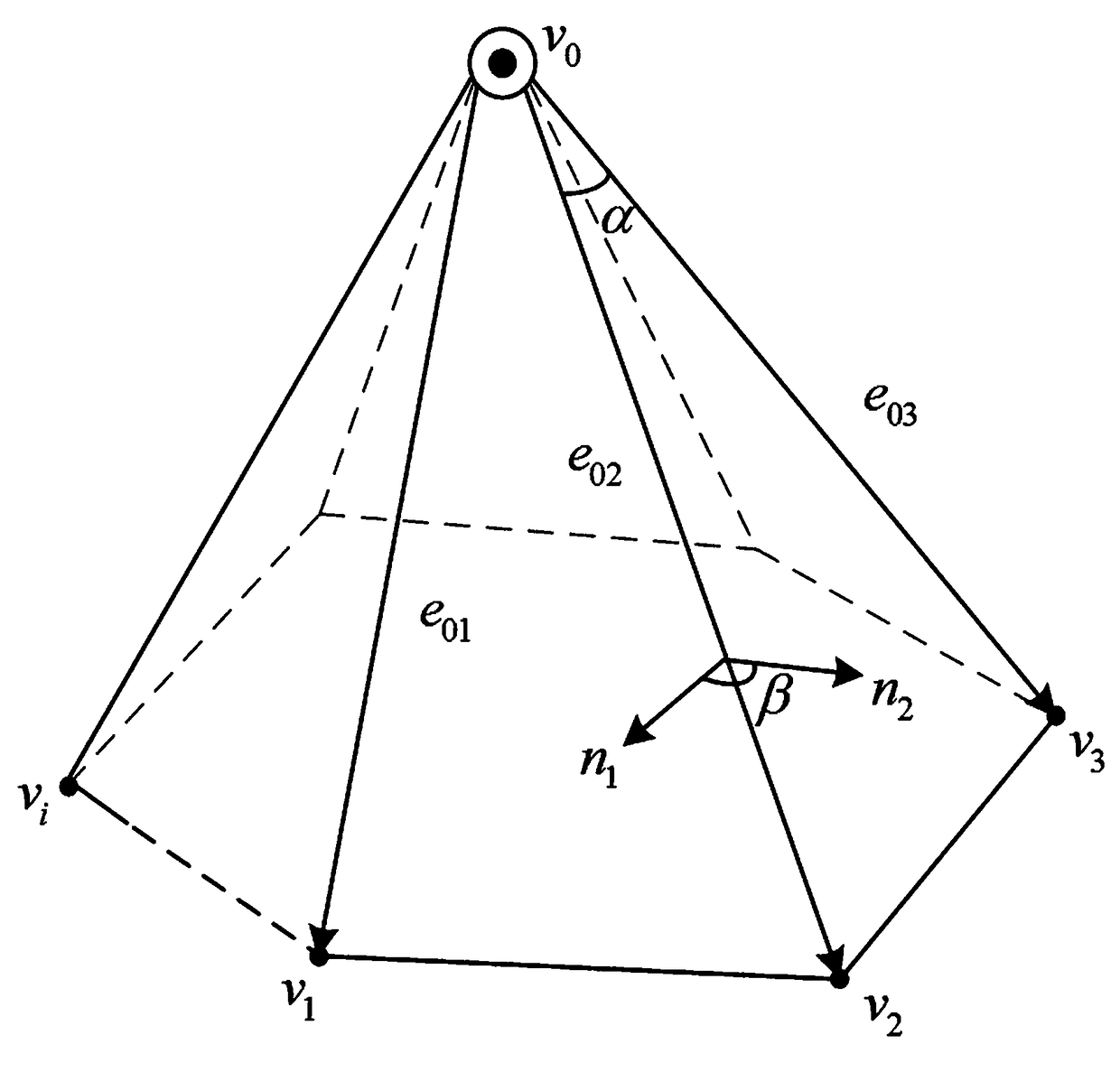

[0051] 1) Detection of characteristic lines: describe the curvature fitting extremum of the corresponding main directions in mathematical definition for the characteristic lines on the surface of the three-dimensional mesh model that can represent significant geometric features;

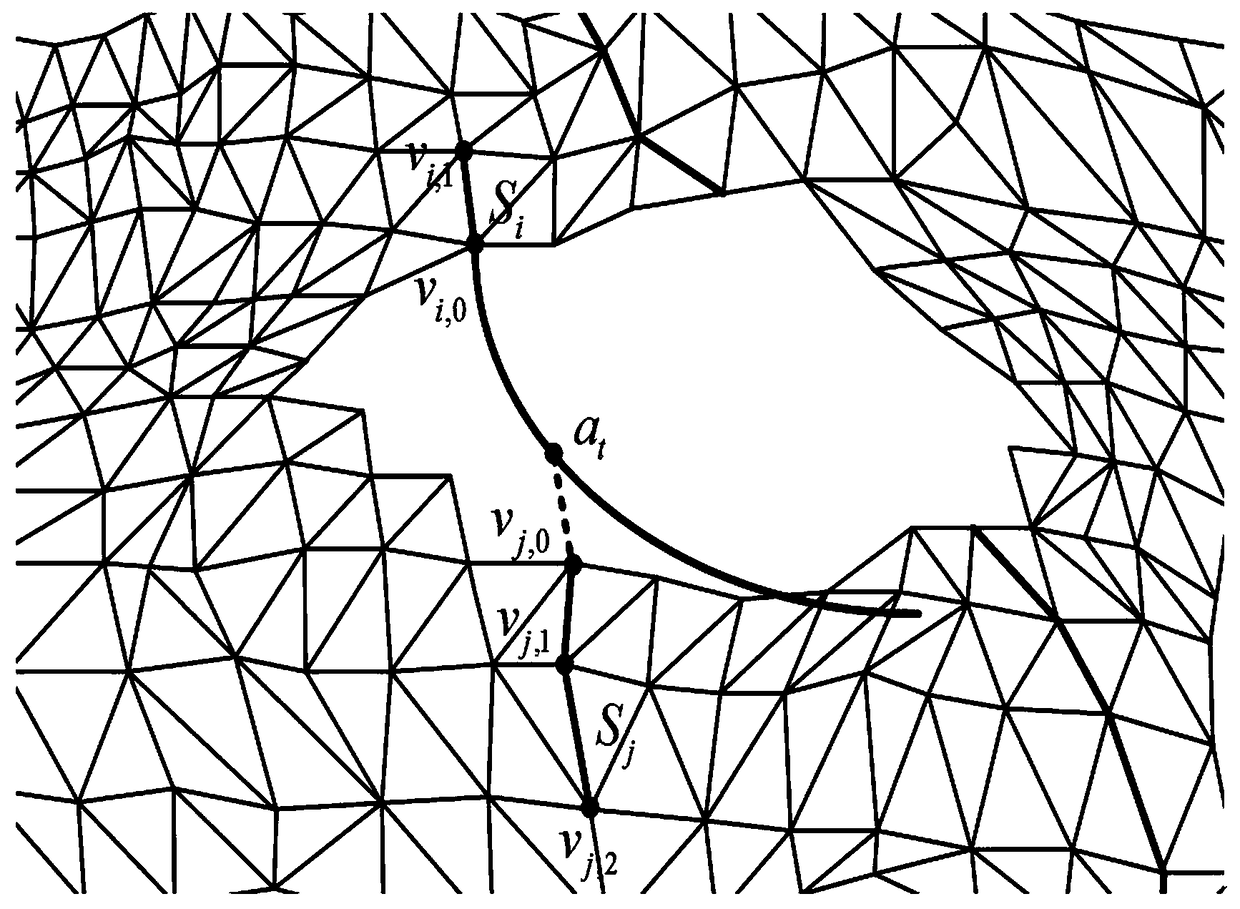

[0052] 2) Matching of characteristic lines: for the characteristic lines detected in step 1), select the optimal matching pair by matching probability (matchingpossibility) measuring standard;

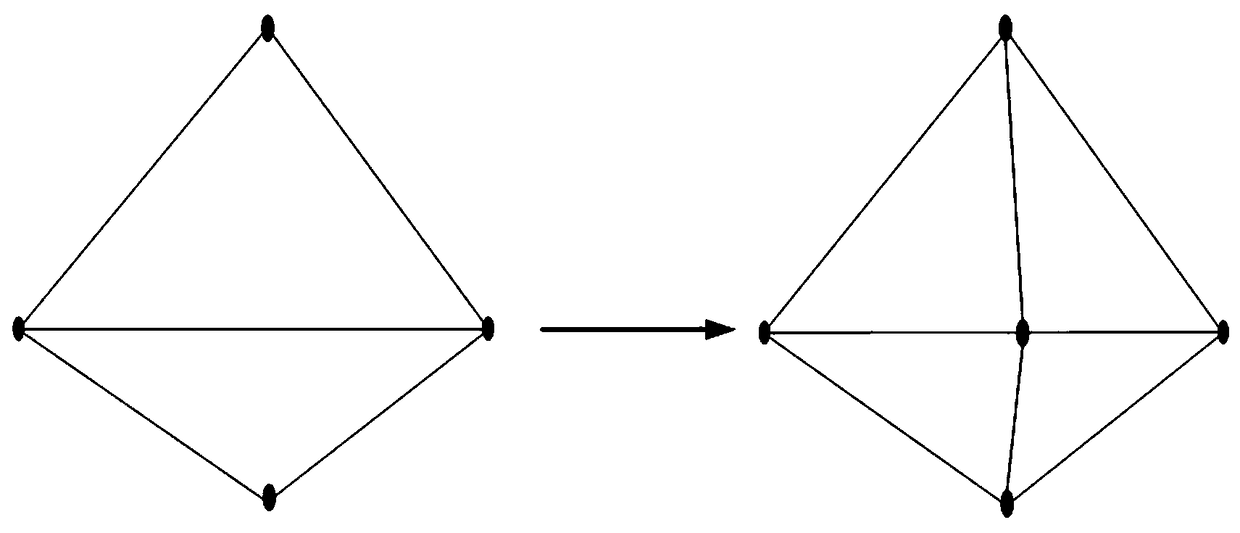

[0053] 3) Triangulation and refinement adjustment: After matching and bridging the characteristic lines, the original hole is partially divided into several simple polygonal sub-holes, and the base surface construction is completed; then Delaunay triangulation and edge are performed on the polygonal sub-holes The calculation of the scoring function assigns an influence factor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com