Stapler power handle

A stapler and power technology, applied in the field of medical devices, can solve the problems of increased use cost, difficult to dissipate heat, inconvenient to operate, etc., and achieve the effects of easy installation and heat dissipation, avoiding scattering or messy, and facilitating overall arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

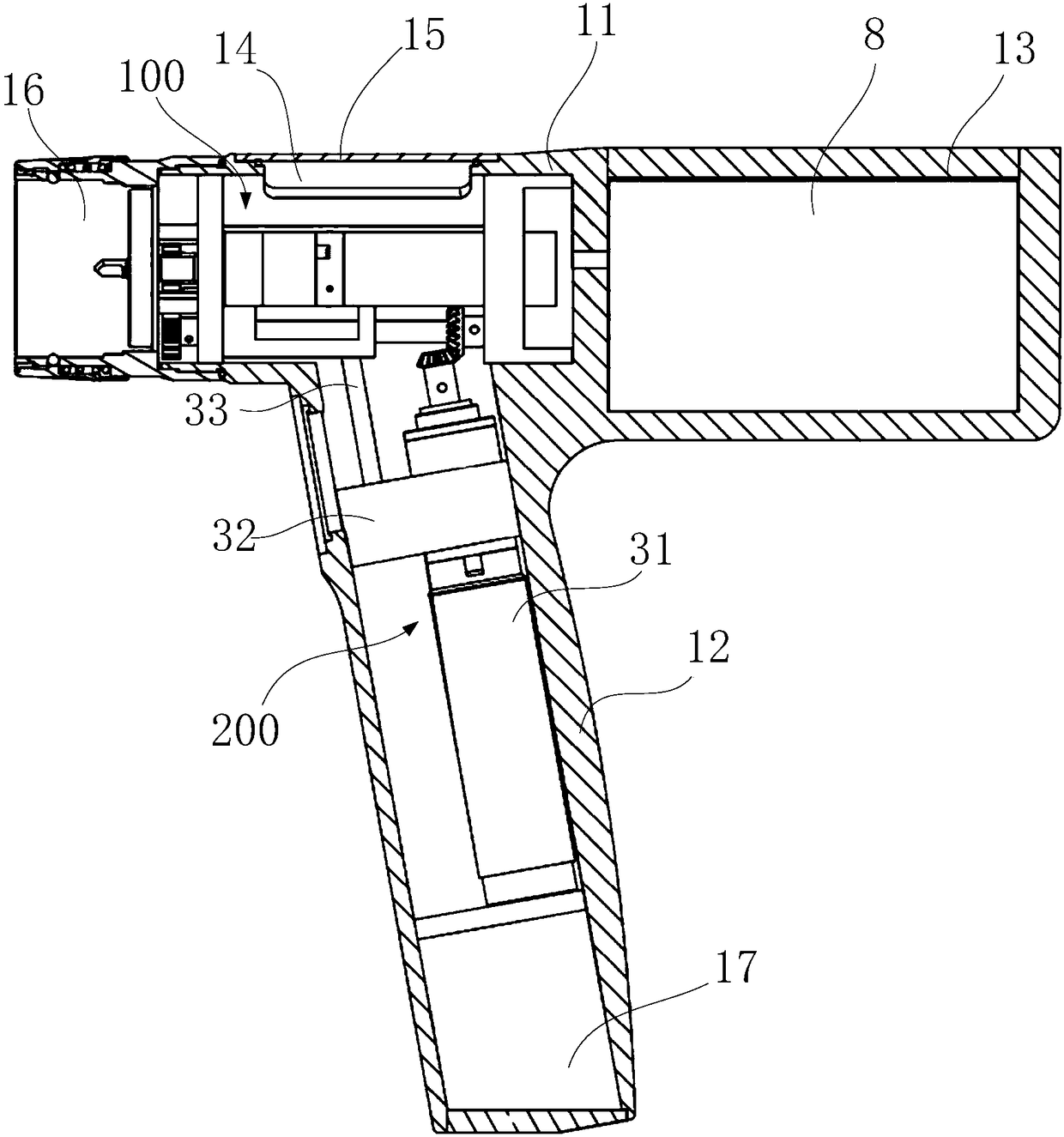

[0079] Such as Figure 1 to Figure 4 As shown, a stapler power handle includes a shell, a power mechanism, and a battery 8. The shell is composed of a shell body 11 and a handle 12. The shell body 11 is arranged horizontally, and the handle 12 is connected below the shell body 11. , the power mechanism includes a first power unit 2 and a second power unit 3, the first power unit is arranged laterally in the middle front of the housing 11, the second power unit is arranged in the handle 12, and the rear of the housing 11 is provided with a battery Compartment 13, the battery 8 is arranged in the battery compartment 13. The power mechanism is dispersedly arranged in the handle 12 and the shell body 11, making full use of the space of the handle 12, simplifying the structure to avoid crowding, and facilitating the installation and heat dissipation of each power unit; and the battery 8 is arranged at the rear of the shell body 11 to play a role Fore and aft balance. Compared wit...

Embodiment 2

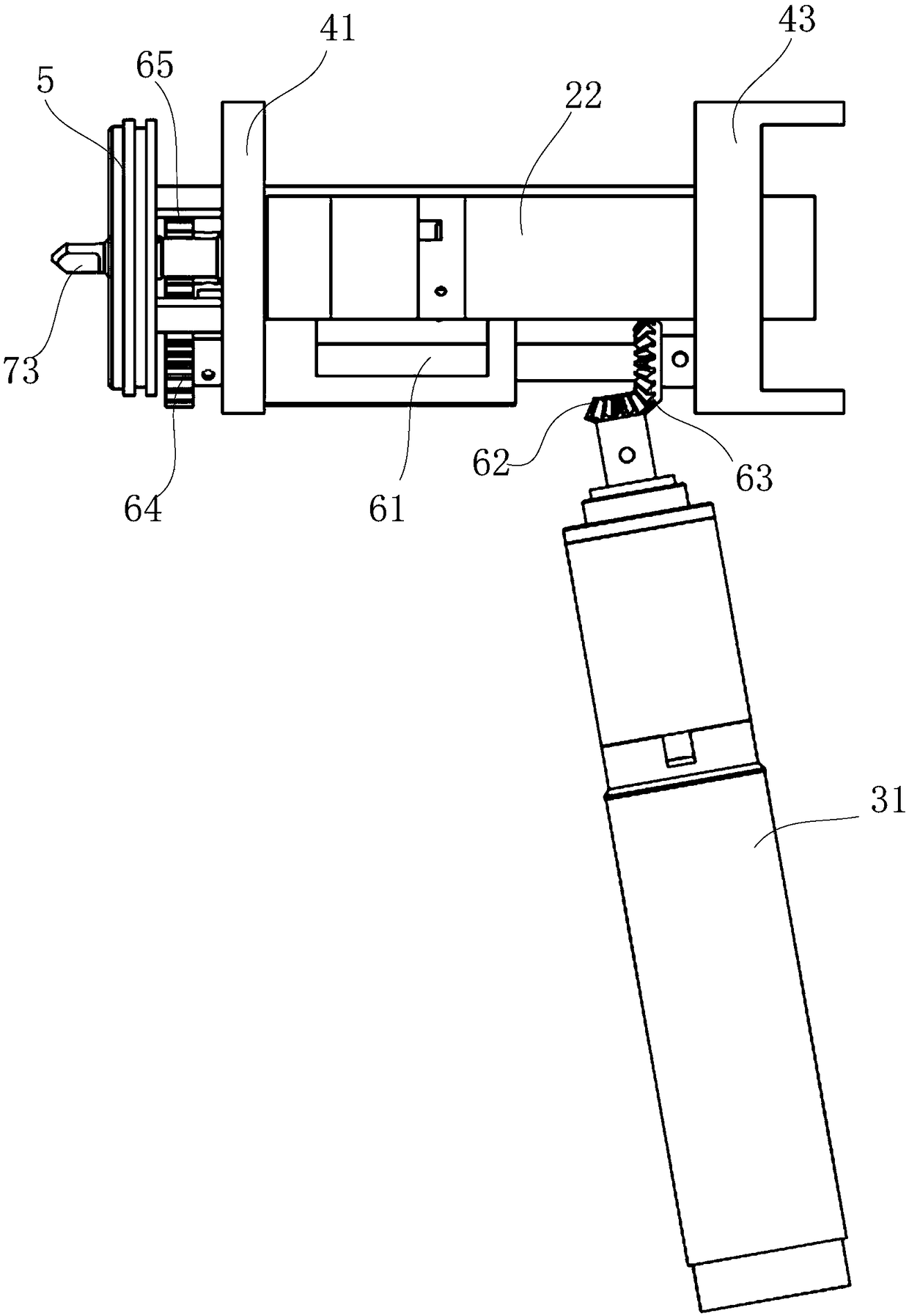

[0105] Such as Figure 7 and figure 2As shown, a power structure of a stapler power handle includes a housing, a plurality of motors and a power head corresponding to the motors, wherein the housing is composed of a housing body 11 and a handle 12, the housing body 11 is arranged horizontally, and the handle 12 Connected under the shell body 11, at least one motor is arranged in the handle, and at least two motors are arranged in the shell body parallel to each other. The motors are dispersedly arranged in the handle 12 and the housing body 11 to make full use of the space of the handle 12, simplify the structure to avoid clustering, and facilitate the installation and heat dissipation of each power unit. Compared with the prior art, the structural arrangement and space utilization are more reasonable.

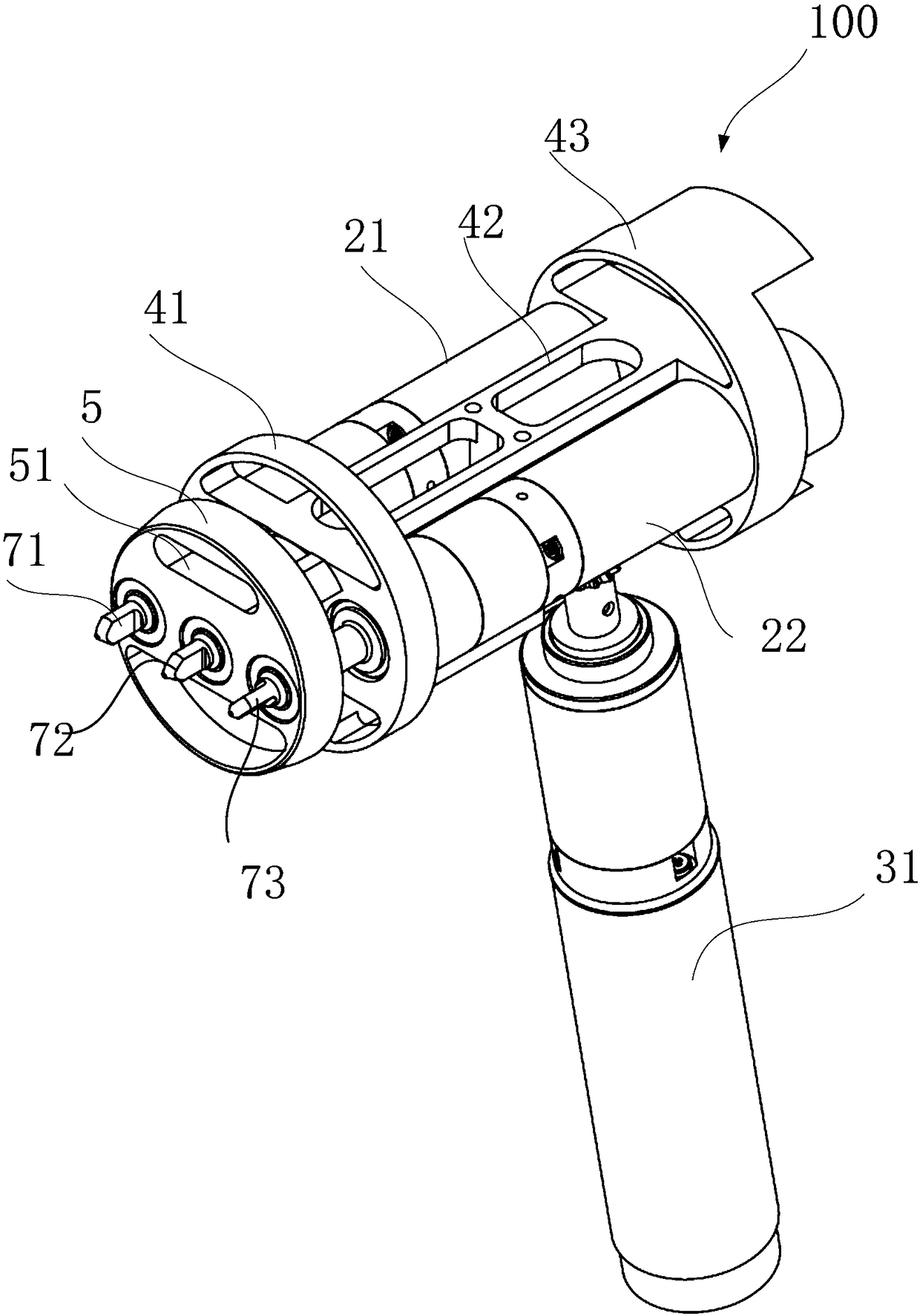

[0106] Wherein, a first motor 21 and a second motor 22 are arranged in the shell body 11 , and a third motor 31 is arranged in the handle 12 . The first motor 21 and the se...

Embodiment 3

[0111] Such as Figure 8 to Figure 6 As shown, on the basis of Embodiment 1, in order to facilitate the installation of the first motor 21, the second motor 22, the transmission mechanism and the power head 71, 72, 73, a support mechanism is also provided, the first motor 21 and the second motor 22 Be installed on the support mechanism, power head 71,72,73 is installed on the support mechanism front.

[0112] Among them, the power heads 71, 72, 73, the first motor 21, the second motor 22 and the main part of the transmission mechanism integrated on the support mechanism form a module; the method of first integrating into a modular structure and then assembling ensures that each The orderly installation of components prevents them from being scattered or messy after being installed in the housing, and facilitates the overall layout of the device structure.

[0113] Such as Figure 6 As shown, the power head includes a power shaft 701 and a flat head 702 located at the front e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com