Preparation method of gypsum boards

A technology of gypsum board and gypsum, which is applied in the field of board materials, can solve the problems that the nail holding force is difficult to meet the actual demand, increase the amount and cost of materials, and the paper surface is not well bonded, so as to improve the efficiency of installation and maintenance, and improve the stability of the internal structure , Improve the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

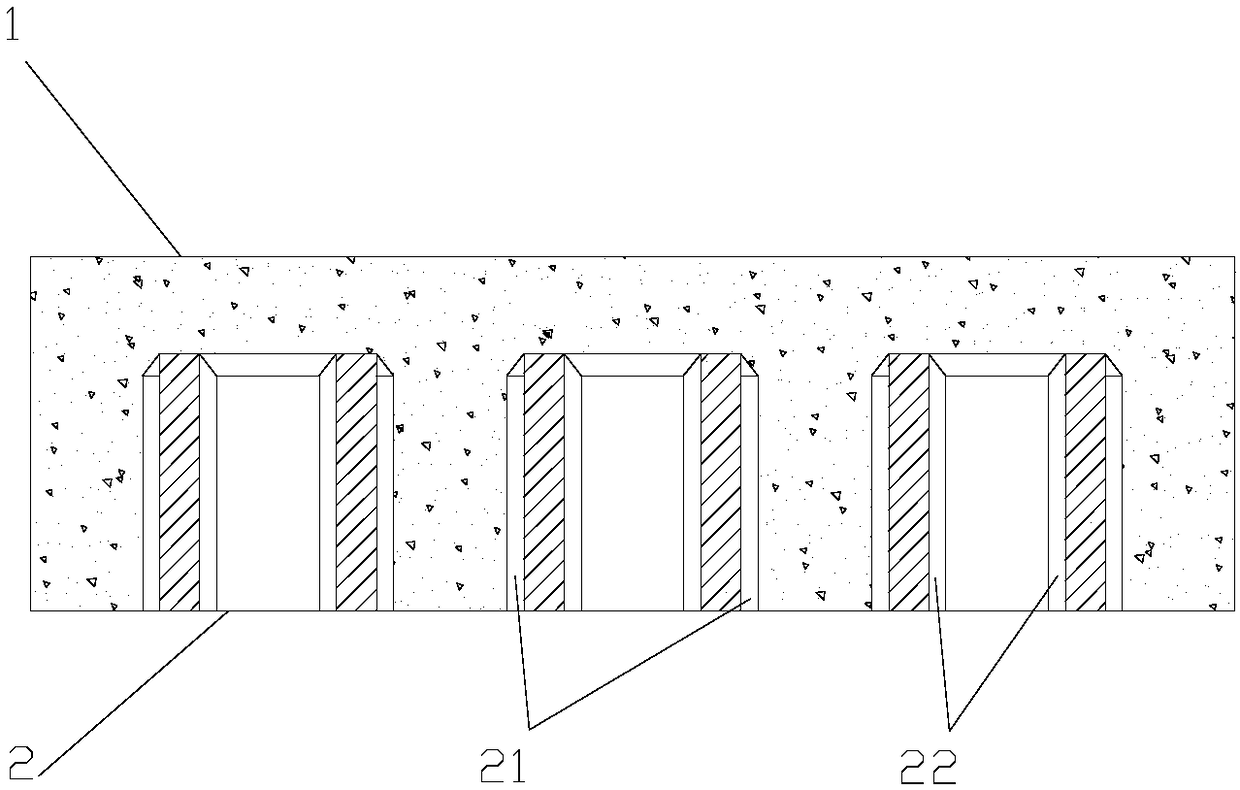

[0044] to combine figure 1 As shown, the embodiment of the present invention provides a gypsum board, which includes a board body 1, and a mounting groove is opened on the board body 1, and the installation groove and the board body 1 are integrally formed; 1. It is fixed on the keel through the cooperation between the installation groove and the keel connector.

[0045] In the specific operation, the fitting connection between the gypsum board and the keel connector can be realized through the setting of the above-mentioned installation groove, and then the gypsum board can be firmly installed on the keel; the above-mentioned installation groove can be arranged on the board body according to the preset distance 1, the corresponding production can be completed in the molding stage; the installation groove and the plate body 1 can be set through the above-mentioned integral molding, which can effectively avoid the uncontrollability of the later on-site processing, and can effec...

Embodiment 2

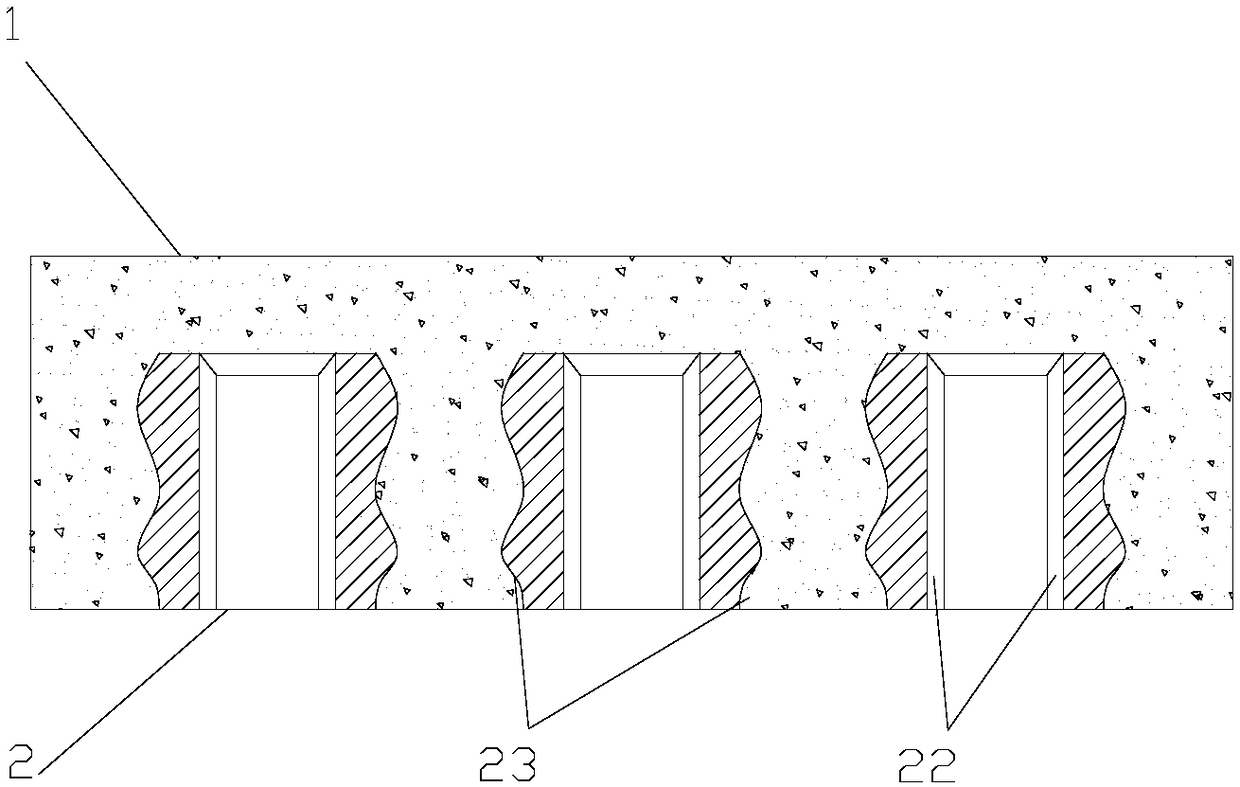

[0054] Embodiment 2 of the present invention provides a gypsum board. The main structure is similar to that of Embodiment 1, and also includes a board body 1, and a mounting groove is also opened on the board body 1; for the specific setting of the main structure, please refer to the first embodiment For the record, the purpose here is to illustrate the difference between the two.

[0055] In this embodiment, the above-mentioned limiting structure is configured as a limiting protrusion 23; the limiting protrusion 23 is arranged on the outer side wall of the embedded block 2, and / or is arranged on the inner side wall of the cylindrical groove.

[0056] to combine figure 2 As shown, in the specific operation, the above-mentioned limiting protrusion 23 is arranged on the outer side wall of the embedded block 2, and the setting of the above-mentioned limiting protrusion 23 can also effectively improve the adhesion between the embedded block 2 and the installation groove, thereby ...

Embodiment 3

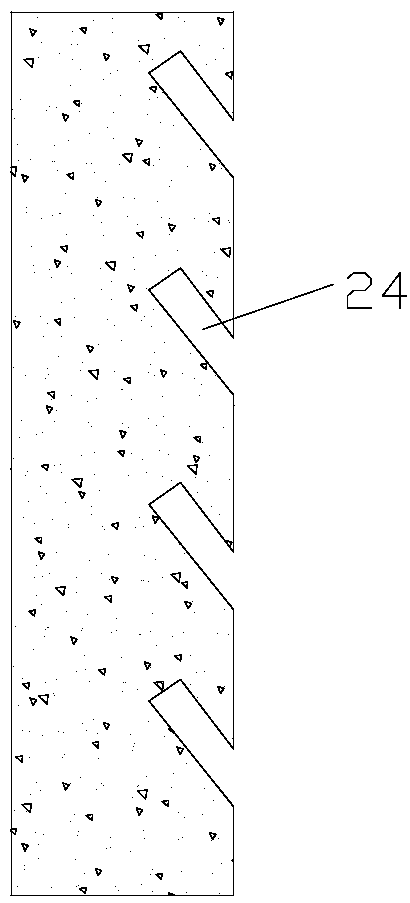

[0060] Embodiment 3 of the present invention provides a gypsum board. The main structure is similar to that of Embodiment 1. It also includes a board body, and an installation groove is also opened on the board body. For the specific configuration of the main structure, please refer to the description in Embodiment 1. The purpose here is to illustrate the difference between the two.

[0061] In this embodiment, adhesive glue is filled between the embedding block and the cylindrical groove.

[0062] In the specific operation, the amount of adhesive glue can be filled between the embedded block and the cylindrical groove, which can also effectively avoid the internal stress concentration of the plate body caused by the limit protrusion or the sharp angle of the external thread structure, and can effectively improve The internal structural stability of the board body can effectively improve the overall structural stability of the gypsum board.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com