Wheat stirring device used for wine brewing

A stirring device and wheat technology, applied in the field of winemaking, can solve problems such as low degree of mechanization, and achieve the effects of reducing floor space, simple structure and sufficient stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

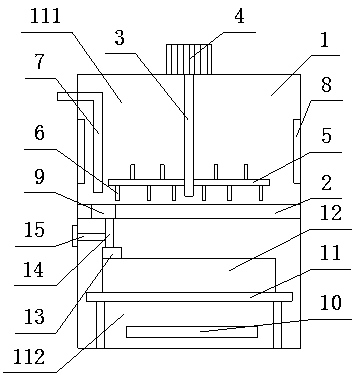

[0010] Embodiment 1: as figure 1 As shown, the present invention includes a reactor 1, the middle part of the reactor 1 is provided with a sealing plate 2, and the sealing plate 2 divides the reactor 1 into two parts, the upper part of the reactor 1 is a stirring and pulverizing part 111, and the lower part It is a dry forming part 112, and a rotating shaft 3 is arranged in the stirring and pulverizing part 111, and the rotating shaft 3 is arranged coaxially with the reactor 1, and one end of the rotating shaft 3 extends out of the reactor 1, and is connected with a drive motor 4, The other end is connected with a stirring blade 5, and the upper and lower sides of the stirring blade 5 are respectively provided with crushing blades 6, and the crushing blades 6 located at the upper and lower sides of the stirring blade 5 are alternately arranged, and one side of the stirring and crushing part 111 of the reaction kettle 1 is provided with There is a dosing pipe 7, a heating pipe ...

Embodiment 2

[0011] Embodiment 2: Same as the above embodiment 1, wherein the above-mentioned stirring blades 5 are provided with two groups.

[0012] In the present invention, the materials are added into the reaction kettle 1 for mixing and stirring reaction, and the driving motor 4 is used to drive the rotating shaft 3. The rotating shaft 3 drives the stirring blade 5 to rotate, and at the same time, the crushing blade 6 rotates to break the lumpy material, so that it can be mixed and stirred more fully. After stirring, it flows to the drying and forming part 112 through the feeding pipe 9, and the material flowing into the forming box 12 is dried and formed by the drying device 10.

[0013] The invention has a simple structure and a reasonable design, can effectively crush the stirred materials to make them more fully stirred, and simultaneously has the function of drying and forming, reduces the occupied area of the equipment, and greatly reduces the production cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com