combustion engine system

A combustion engine, internal combustion engine technology, applied in the direction of combustion engine, internal combustion piston engine, engine components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

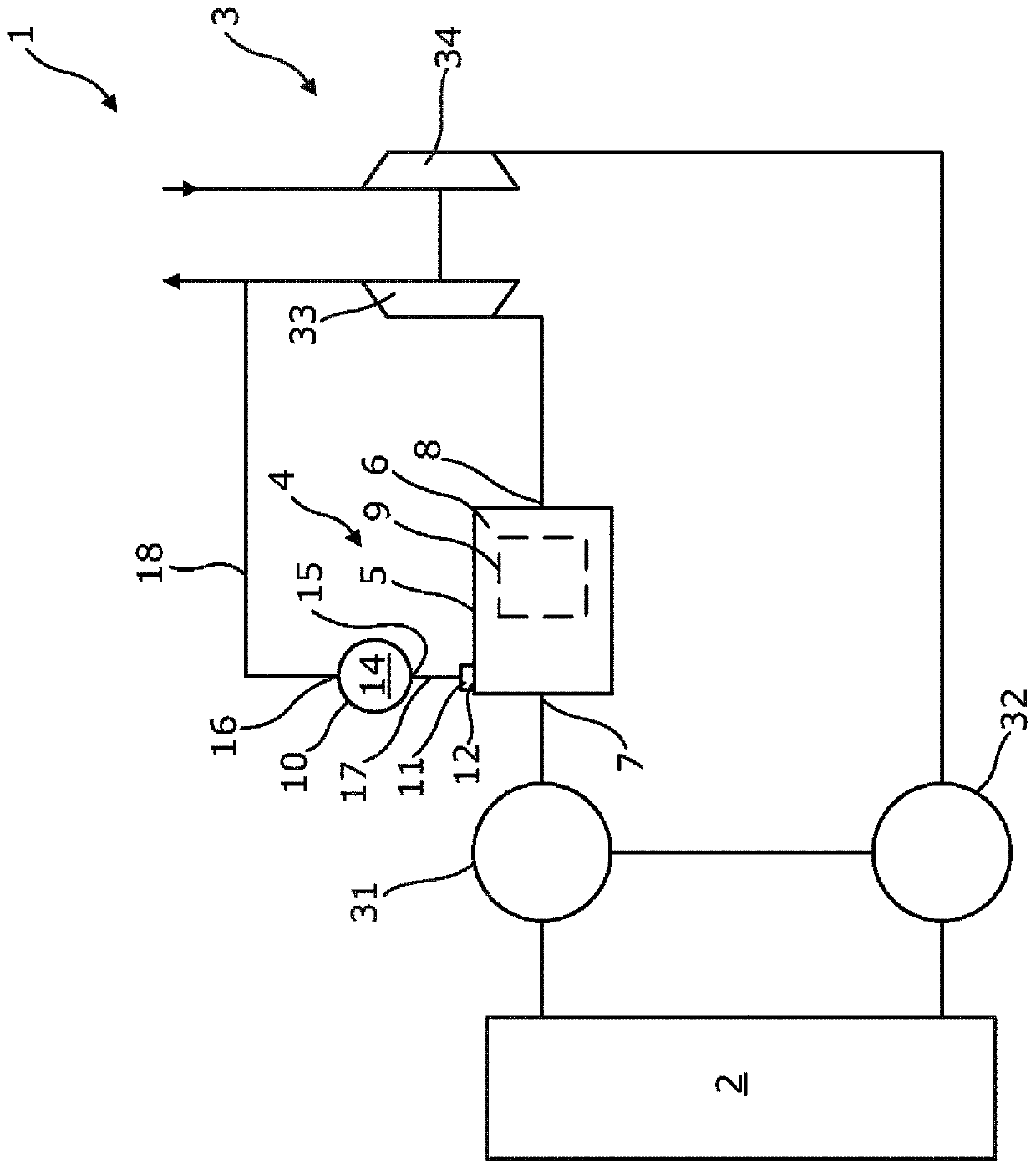

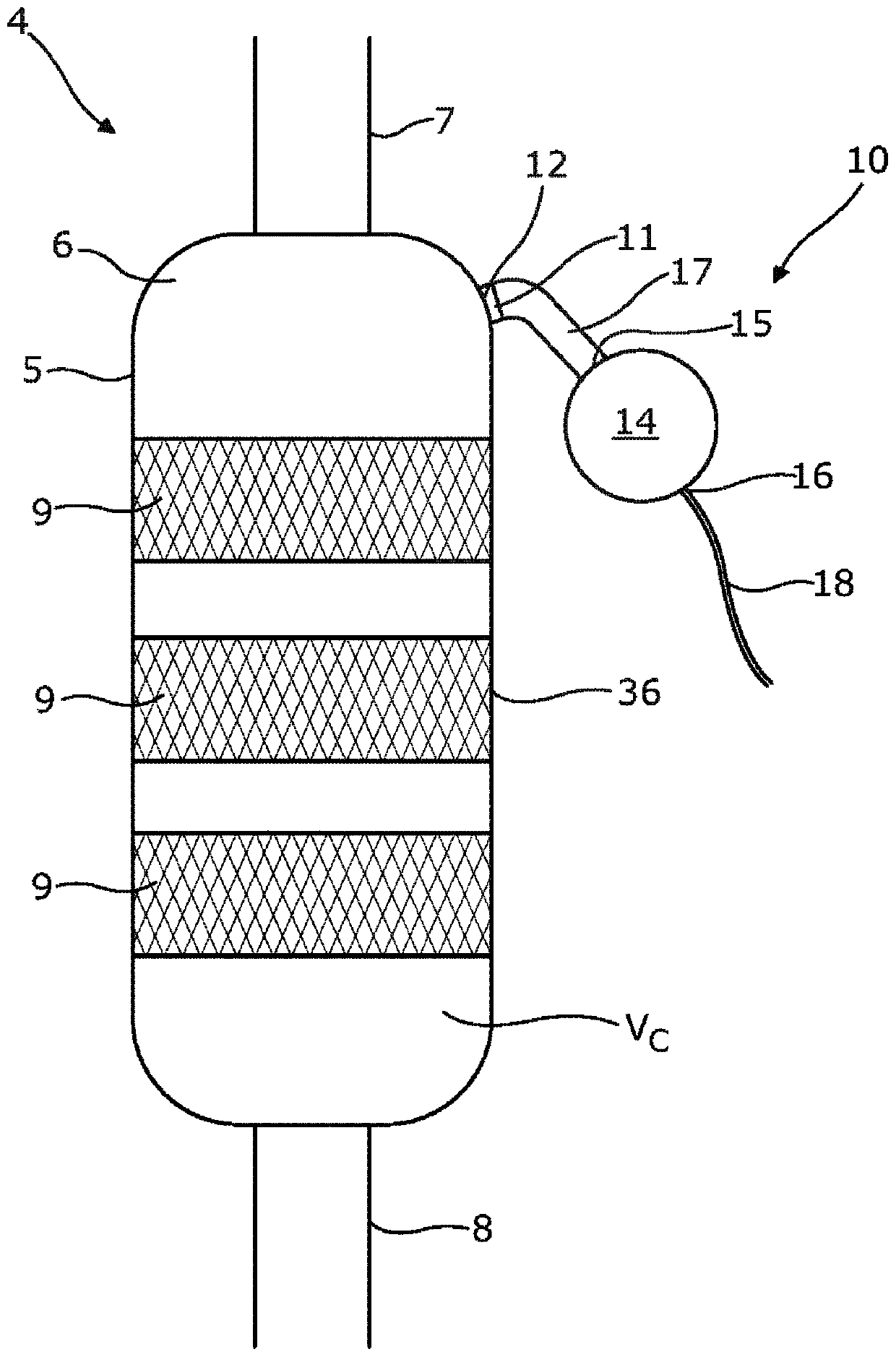

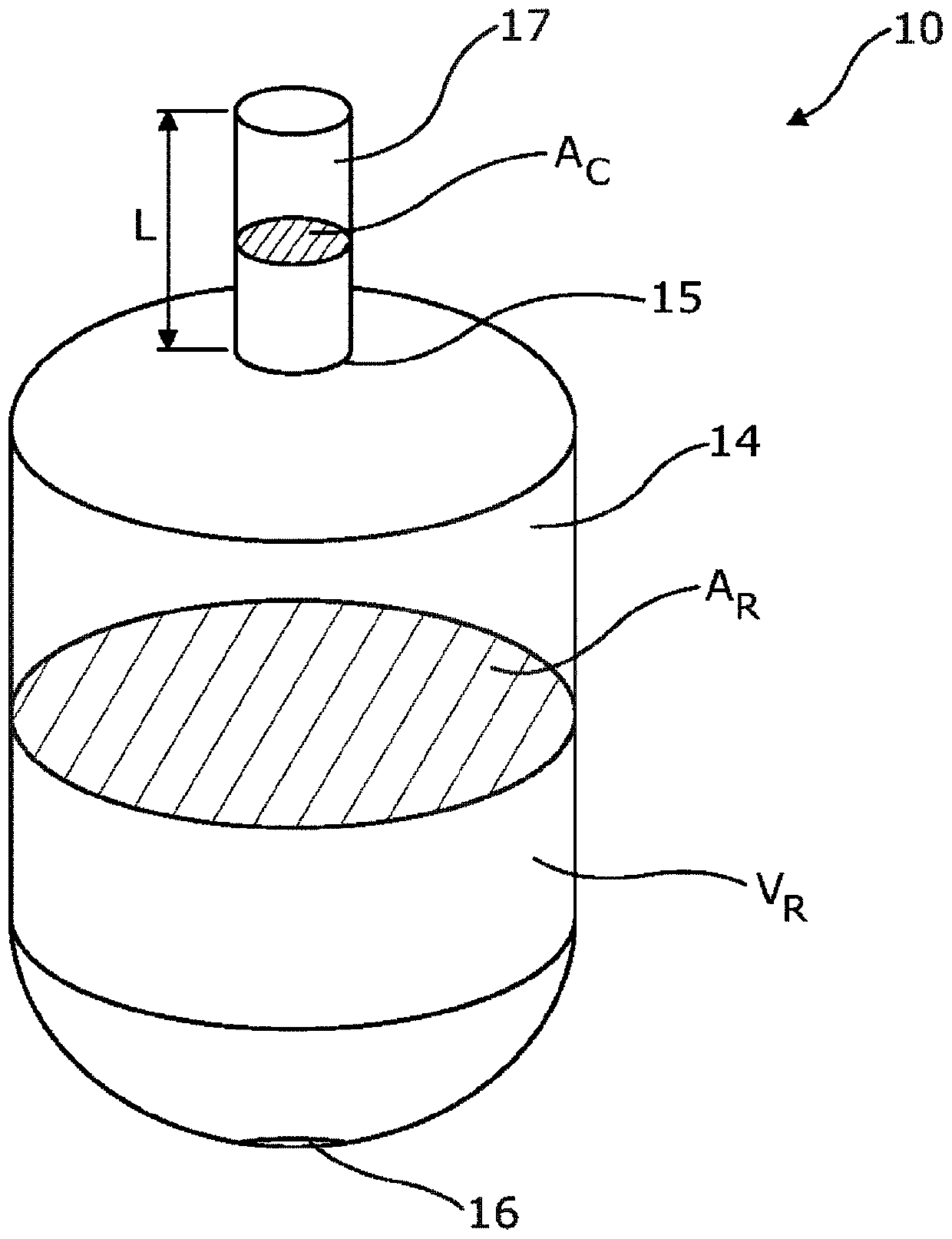

[0059] figure 1 A combustion engine system 1 is shown which includes an internal combustion engine 2 producing exhaust gas. The combustion engine system 1 comprises a turbocharger 3 , which is driven by exhaust gases from the high-pressure side of the turbocharger 3 . The combustion engine system 1 also includes a NO x A reduction unit 4, which is in fluid communication with the internal combustion engine 2, to purify the exhaust gas from the internal combustion engine 2 by selective catalytic reduction (SCR). NO x The reduction unit 4 comprises a catalytic reactor housing 5 with a chamber 6, an inlet pipe 7, an outlet pipe 8 and one or more catalytic elements 9 arranged in a catalytic converter between the inlet pipe 7 and the outlet pipe 8. In the chamber 6 of the reactor shell 5 . in NO xIn the reduction unit 4 , soot deposits on the catalytic elements 9 and on all surfaces within the catalytic reactor housing 5 during exhaust gas purification. Therefore, the combusti...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap