Bearing unit

A technology of bearings and rolling bearings, applied in the direction of bearing components, shafts, bearings, rigid supports of bearing components, etc., can solve the problems of slowing down the installation process, fixed costs, and high costs, and achieve the effect of reducing the bearing surface and reducing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

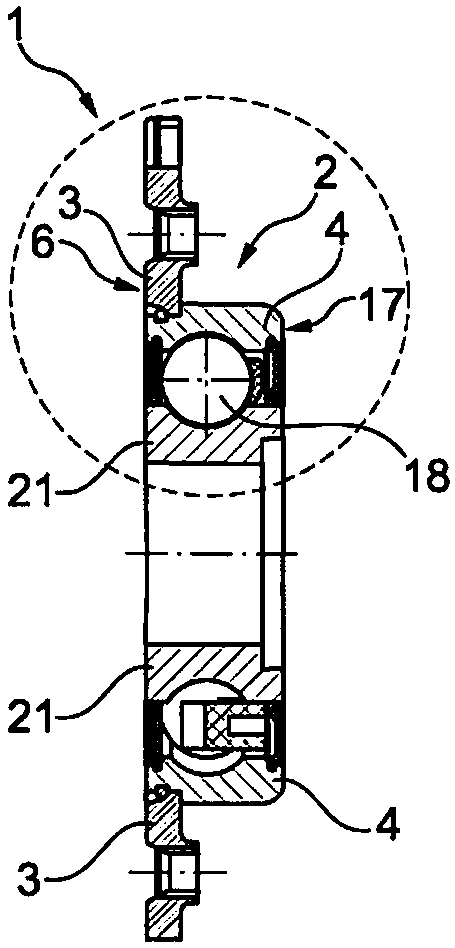

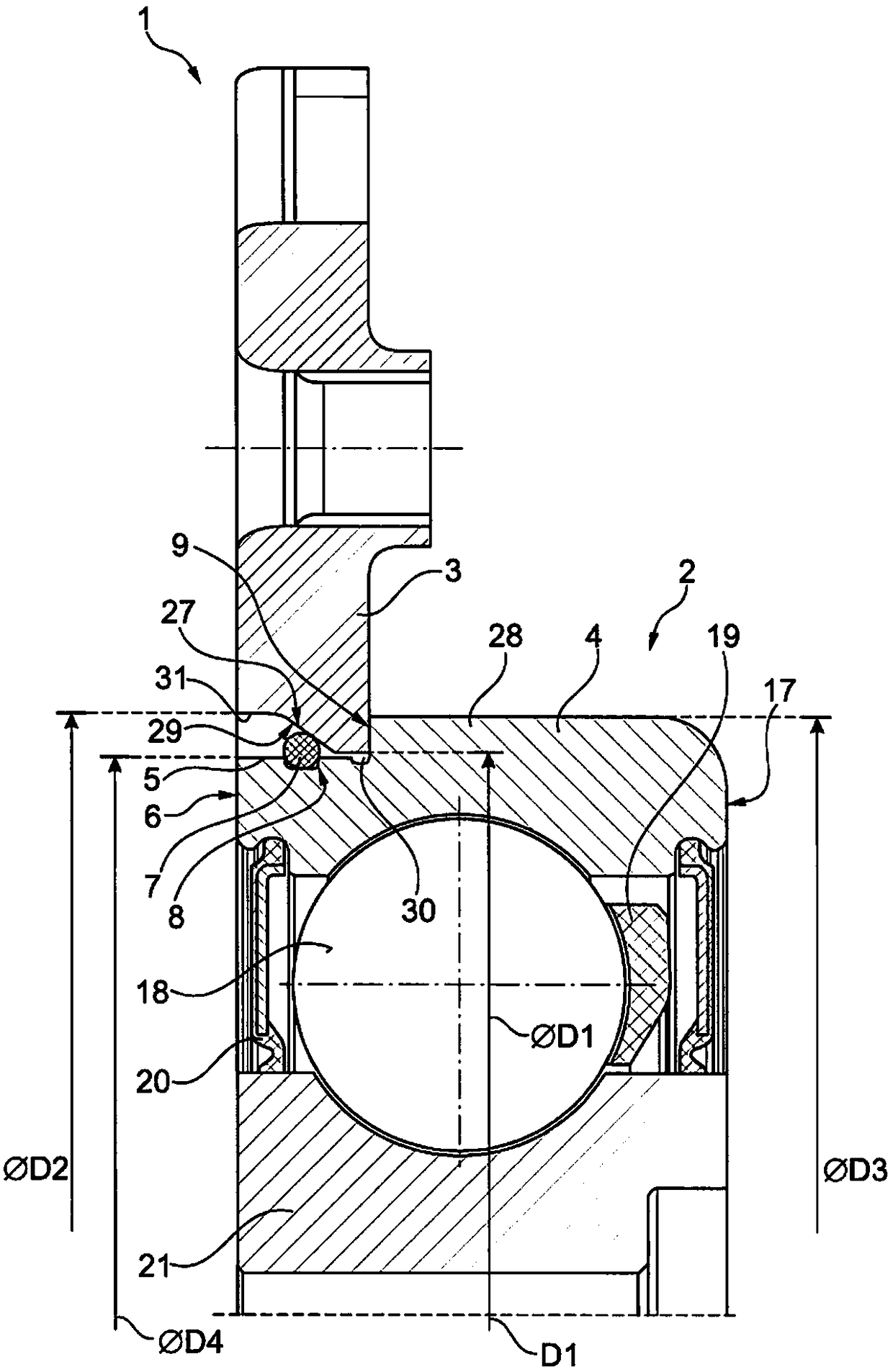

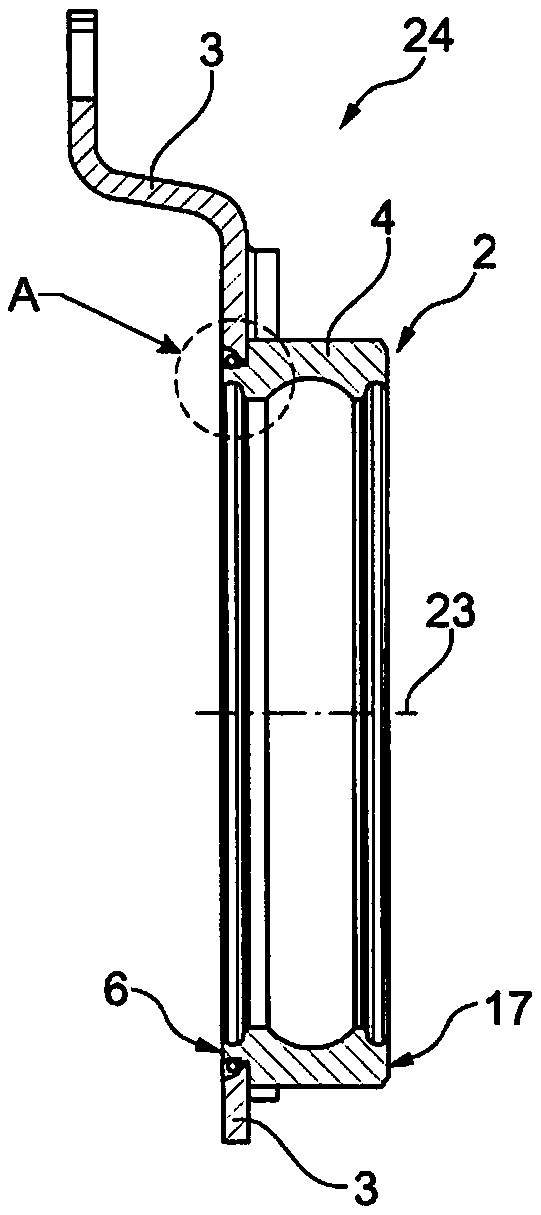

[0035] exist figure 1 and 2 A bearing unit 1 according to the invention is shown in . The bearing unit 1 comprises a rolling bearing 2 and a holding plate 3 as well as a locking element 7 by means of which the holding plate 3 is fixed on the rolling bearing 2 . The rolling bearing 2 has an outer ring 4 and an inner ring 21 , a plurality of rolling bodies 18 being arranged between the inner ring 21 and the outer ring 4 . The rolling bodies 18 are guided by a cage 19 and kept spaced apart from one another. Furthermore, a sealing element 20 is formed on the rolling bearing 2 in order to prevent lubricant from escaping from the rolling bearing 2 .

[0036] The outer ring 4 has a first end side 6 and a second end side 17 opposite the first end side 6 . A shoulder 5 is formed on the side of the outer ring 4 facing the first end side 6 , which shoulder carries the retaining plate 3 . The shoulder 5 is indicated by a radial diameter step 28 . The diameter step 28 is described by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com