Detonator positioning and scanning fixing device

A technology of positioning scanning and fixing device, applied in the direction of electromagnetic radiation induction, etc., can solve the problems of issuing errors, multi-manpower time, and many human factors, and achieve the effect of reducing overall cost, improving safety, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further understand and recognize the structure, features and effects of the present invention, a preferred embodiment is now given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

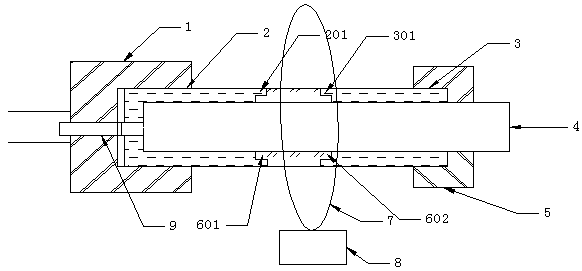

[0025] Such as figure 1 As shown, the detonator positioning mechanism of the present invention includes: a first base 1, a first non-transparent material part 2, a first shoulder 201, a second non-transparent material part 3, a third shoulder 301, and a detonator 4. The second base 5 , the transparent part 6 , the second shoulder 601 , the fourth shoulder 602 , the ring scanner 7 , the supporting frame 8 and the position sensor 9 .

[0026] Such as figure 1 As shown, the sleeve is used to accommodate the detonator 4, and the sleeve includes: a non-transparent material part 3 and a transparent part 6; the non-transparent material part includes: a first non-transparent material part 2 and a second non-transparent material part 3 , the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com