Novel high-frequency glass cutting head

A high-frequency, new technology, applied in the field of new high-frequency glass cutting head, can solve the problems of large volume, low cutting and suction efficiency, and complex design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

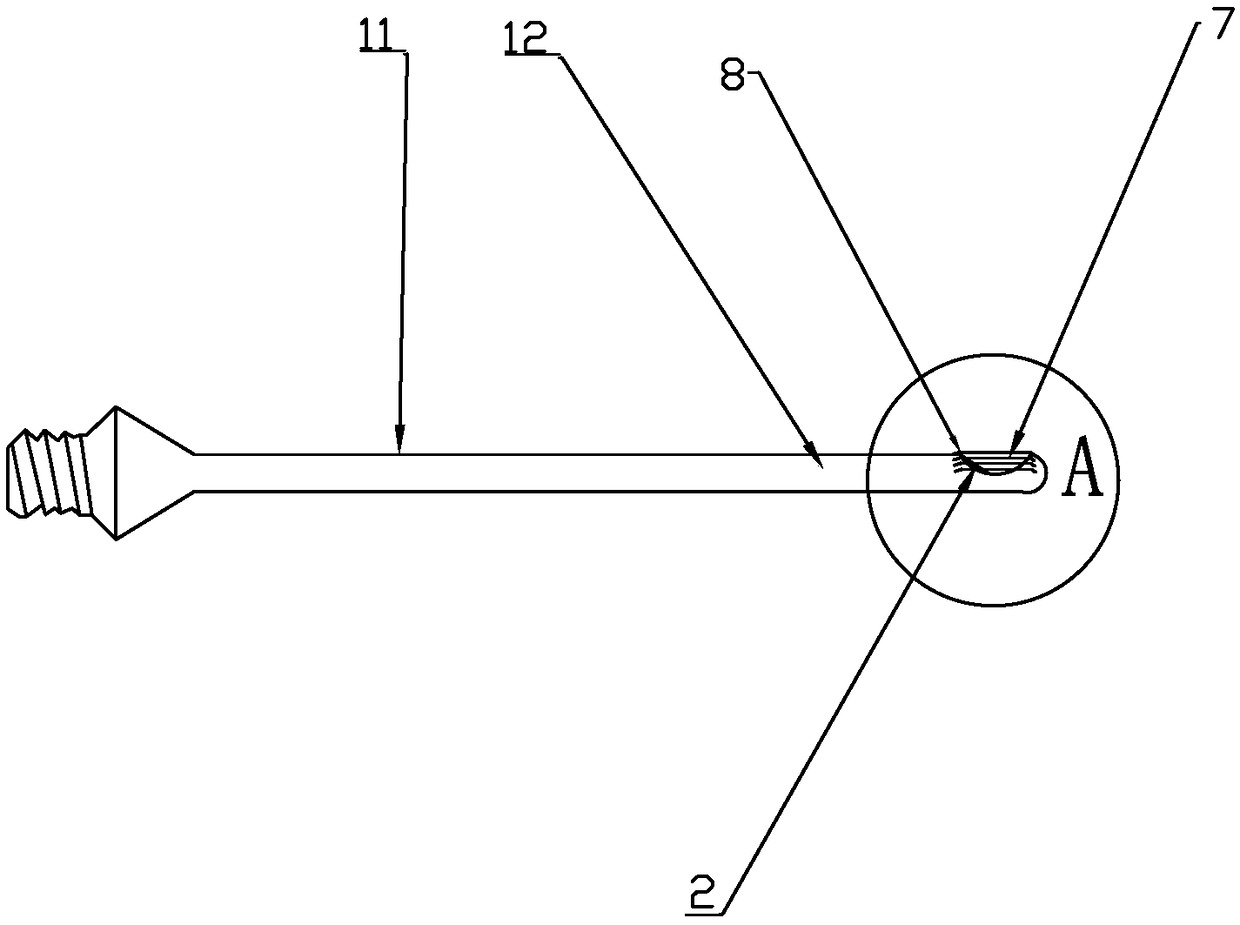

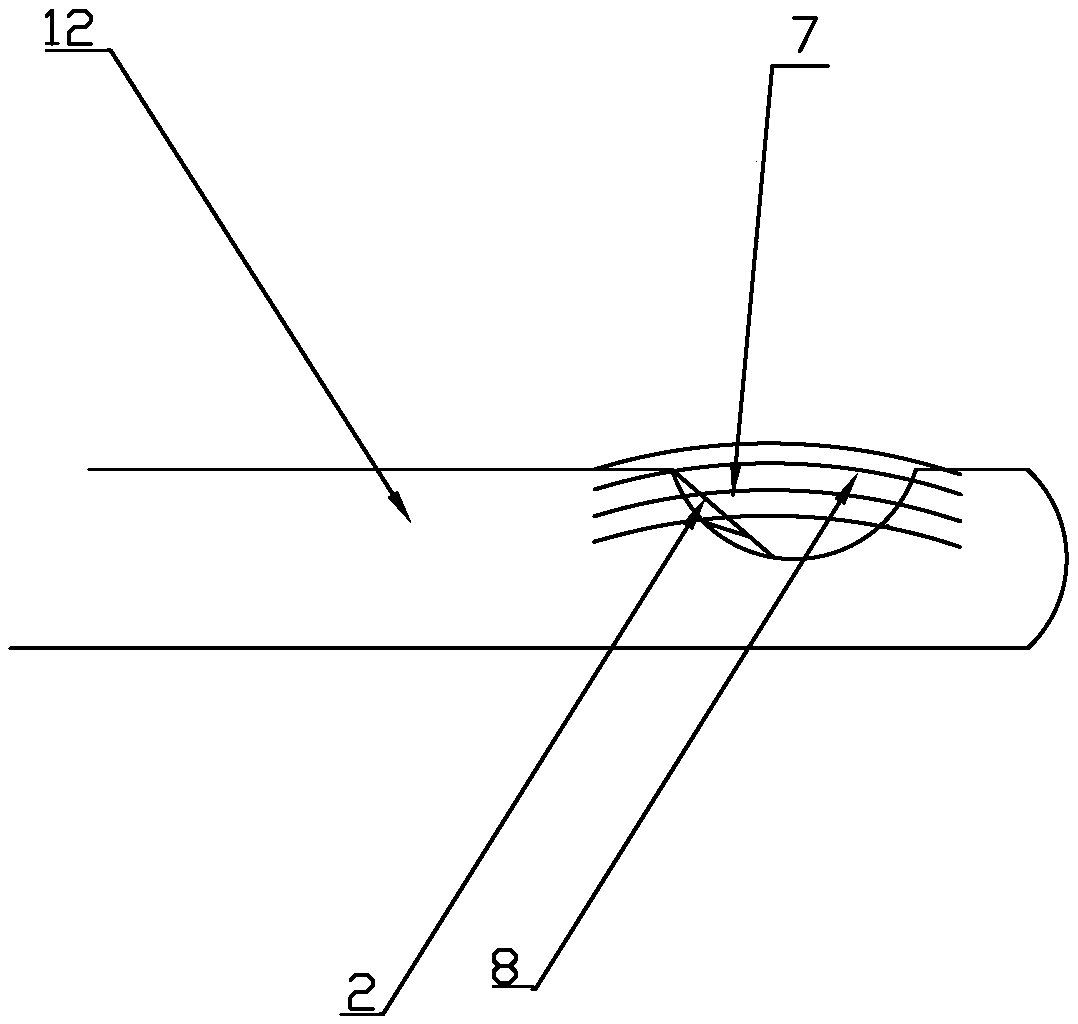

[0024] Such as Figure 1-5 As shown, a novel high-frequency glass cutting head includes an insertion structure, and the insertion structure includes a main body part 11 and a cutting part 12 that are connected to each other in a single-layer pipe-like structure, and the cutting part 12 is arranged on the side of the main body part 11. front end;

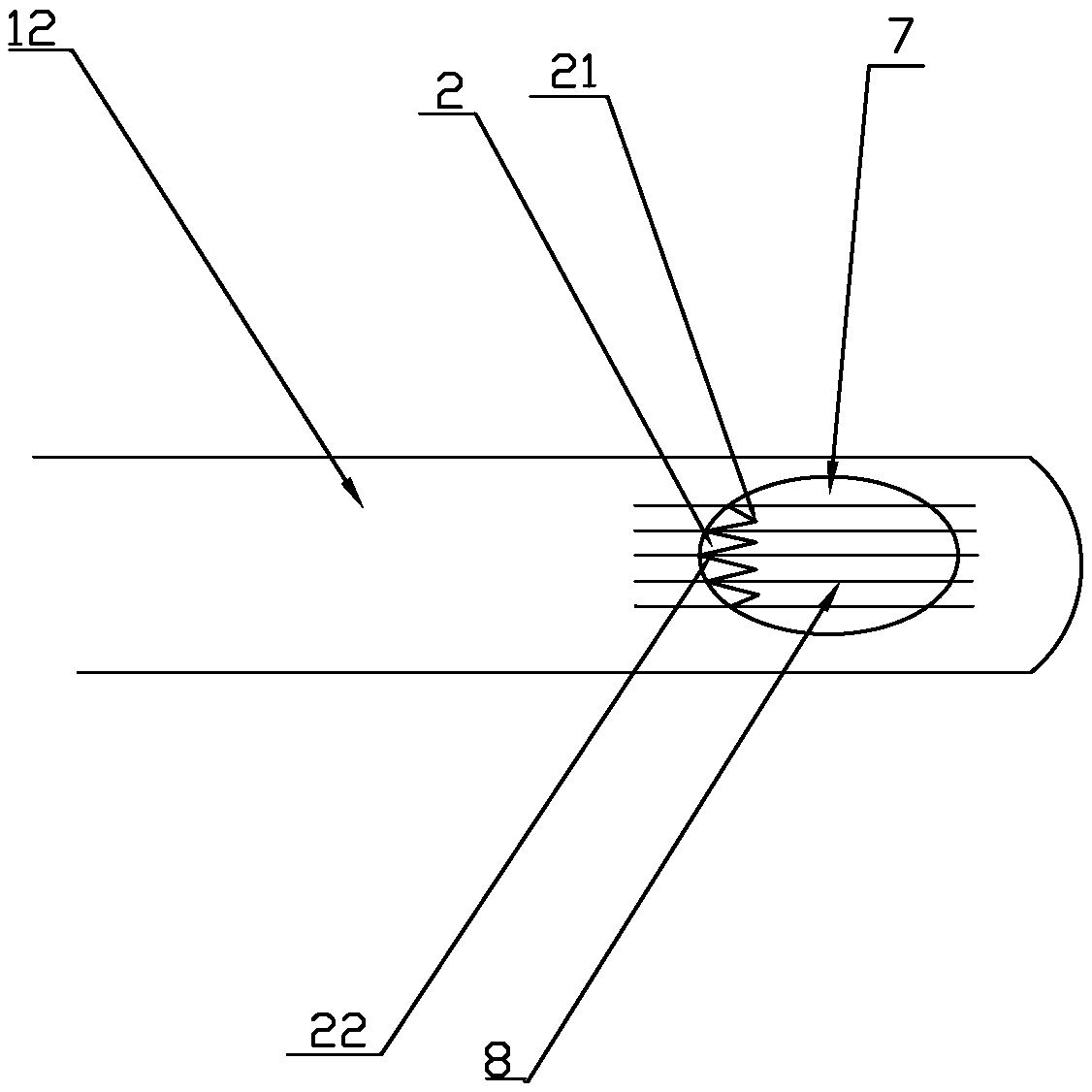

[0025] At least one suction hole 7 is provided on the surface of the cutting part 12, and the suction hole 7 communicates with the inner cavity of the insertion structure; a plurality of cutting wires 8 are regularly arranged on the surface of the suction hole 7, and the cutting wires 8 span the Above the suction hole 7, its two ends are fixed on the surface of the cutting part 12, and a zigzag notch 2 is provided at the fracture of the cutting part at the side edge of the suction hole 7, and the zigzag notch 2 includes intervals. The teeth 21 and the alveoli 22, and the cutting wire 8 above the zigzag notch 2 are all located direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com