Energy-saving reaction kettle

The technology of a reaction kettle and a reaction kettle body is applied in the field of energy-saving reaction kettles, which can solve the problems of long time consumption, unfavorable popularization and high production cost, and achieves the effect of saving operation time and facilitating popularization and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions of the present invention will be described in detail below in conjunction with specific embodiments. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

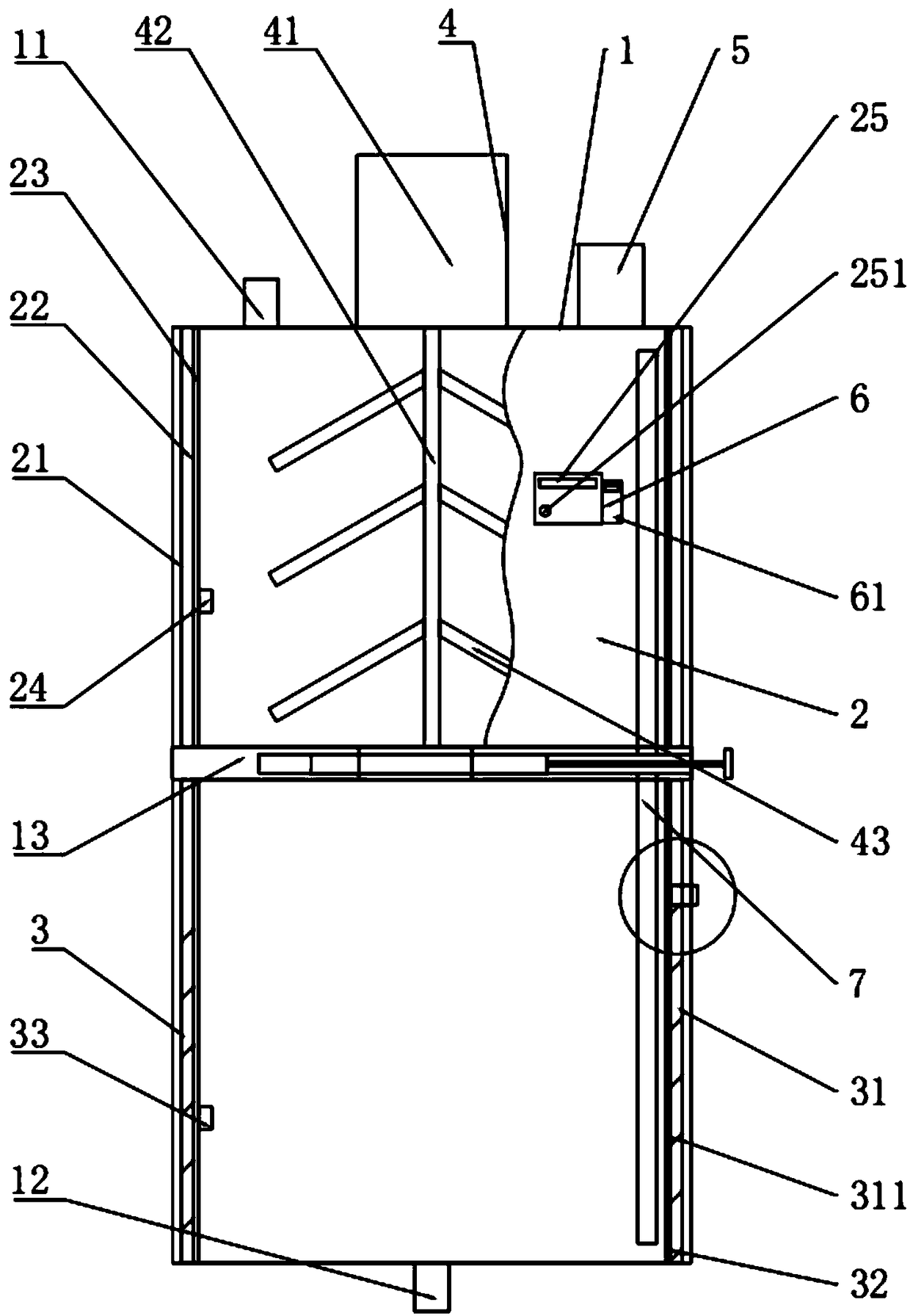

[0037] Such as Figure 1-3 As shown, the present invention provides an energy-saving reactor, comprising a reactor body 1, the upper and lower ends of the reactor body 1 are respectively provided with a feed inlet 11 and a discharge outlet 12; materials are fed through the feed inlet 11, crystallized Finally, the material is discharged through the discharge port 12, and the material moves according to its own gravity;

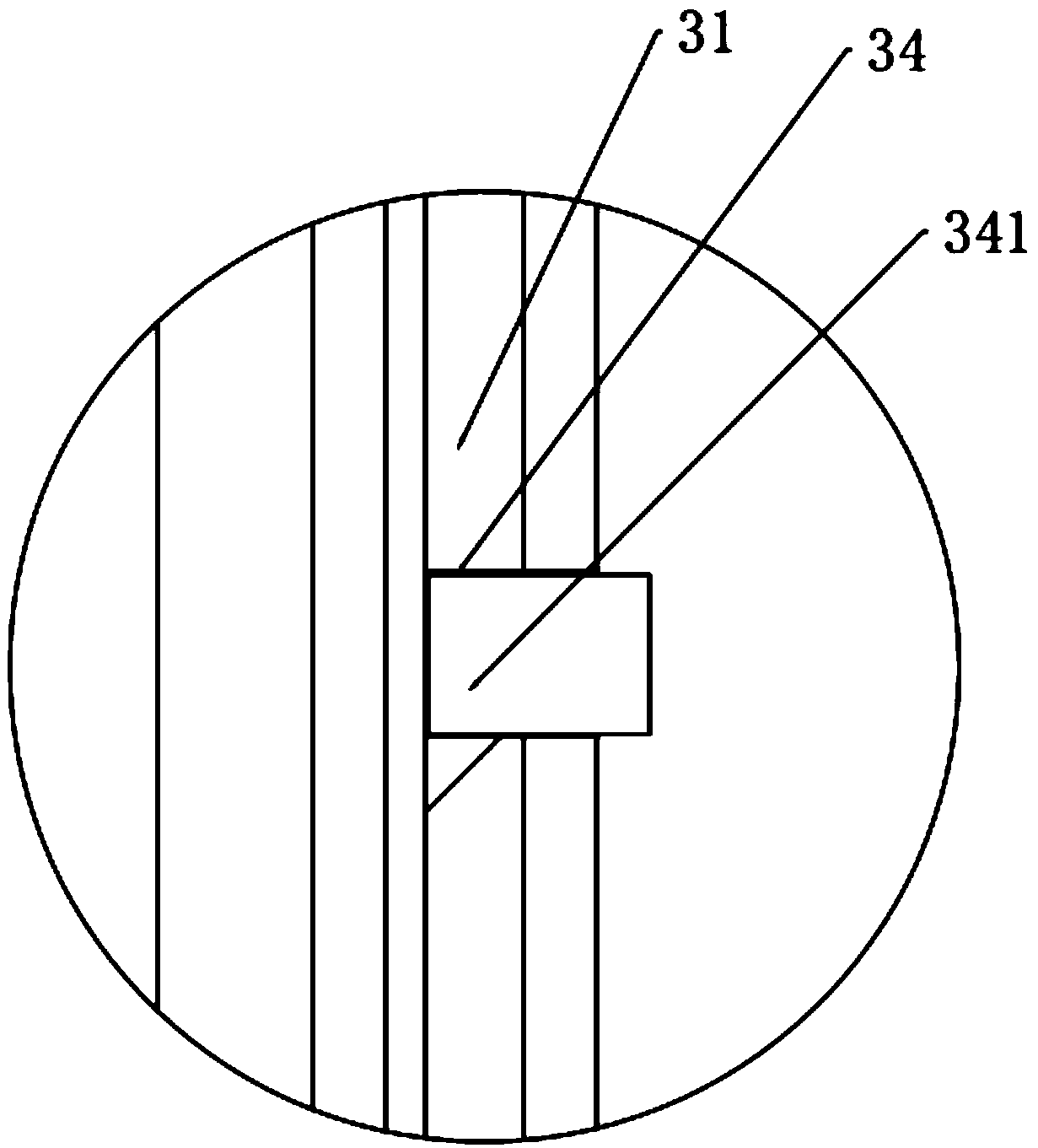

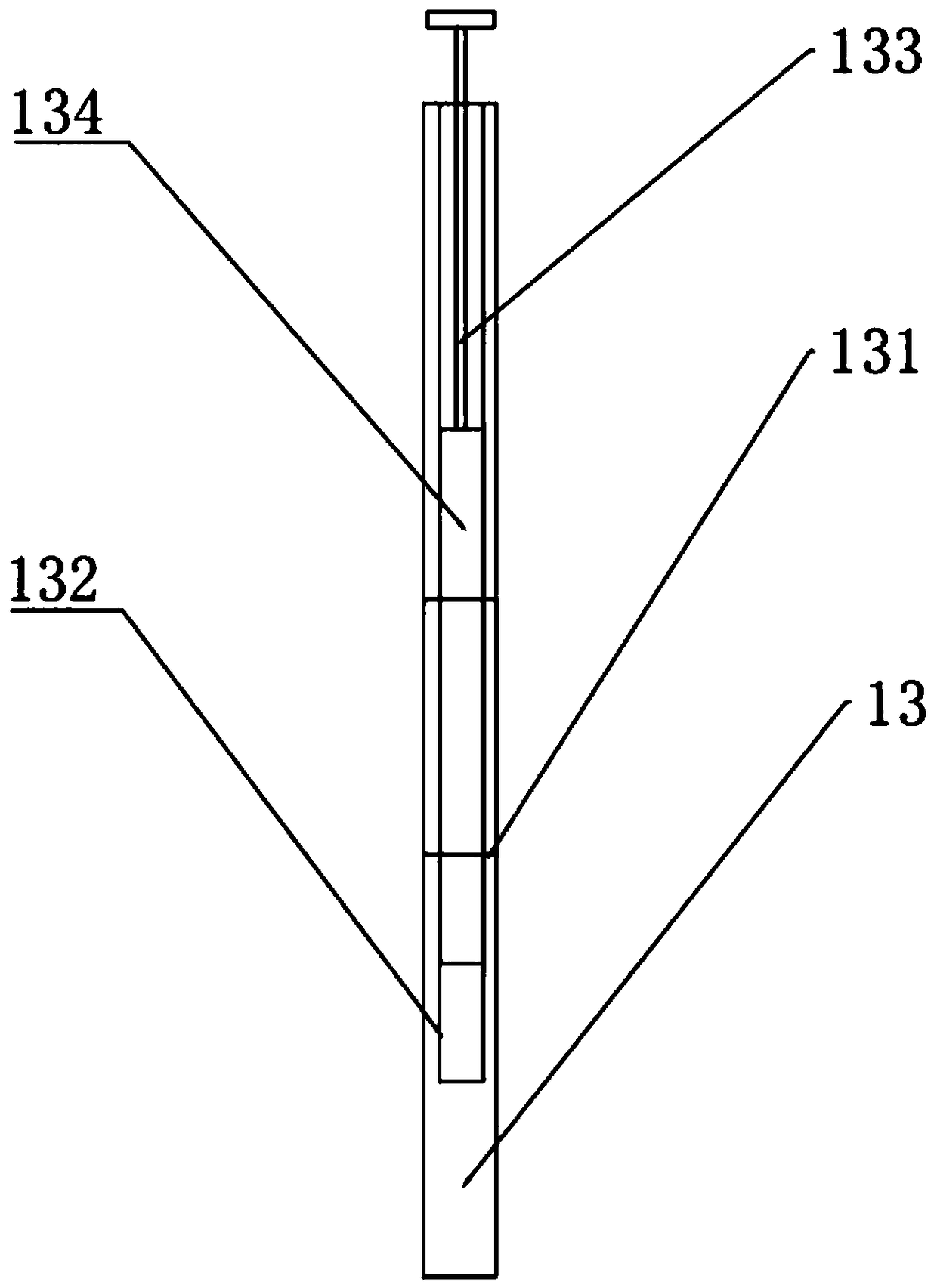

[0038] The middle end of the reactor body 1 is provided with a partition 13, and the partition 13 divides the reactor body 1 into a reaction zone 2 and a crystallization zone 3; the top of the partition 13 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com