Energy-saving swirler

A cyclone and distributor technology, which is applied to cyclone devices, devices whose axial directions of cyclones can be reversed, etc., can solve the problems of grading quality fluctuation, large flow rate, and large pressure drop, and achieve a balanced working flow, The effect of reducing operators and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

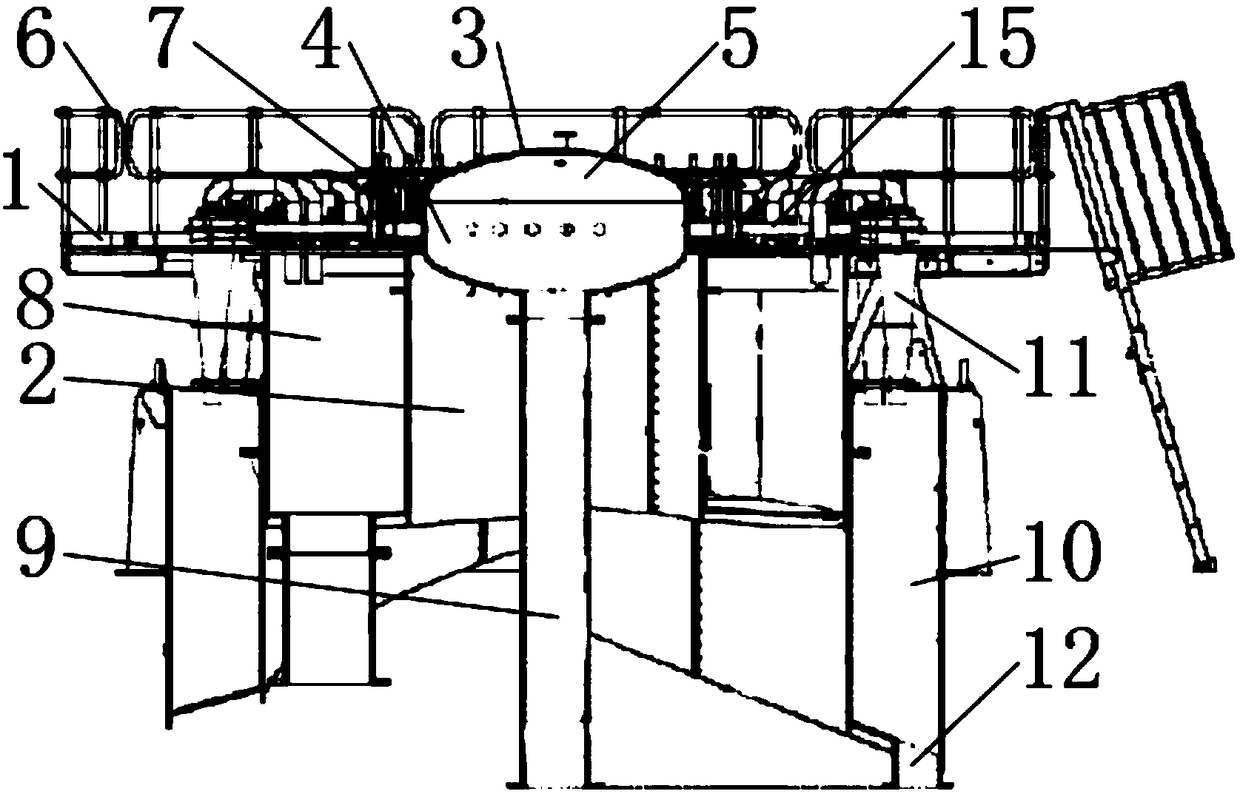

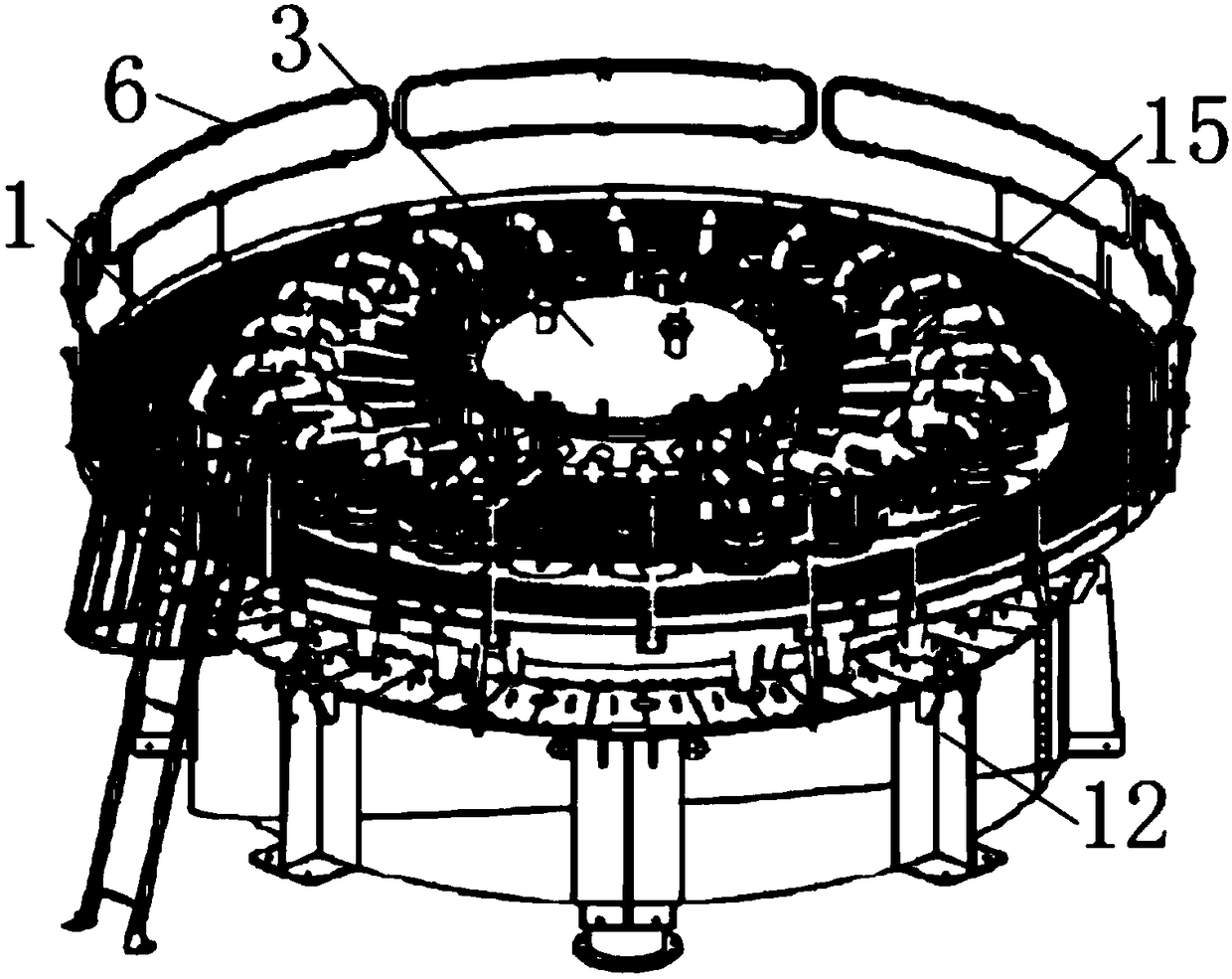

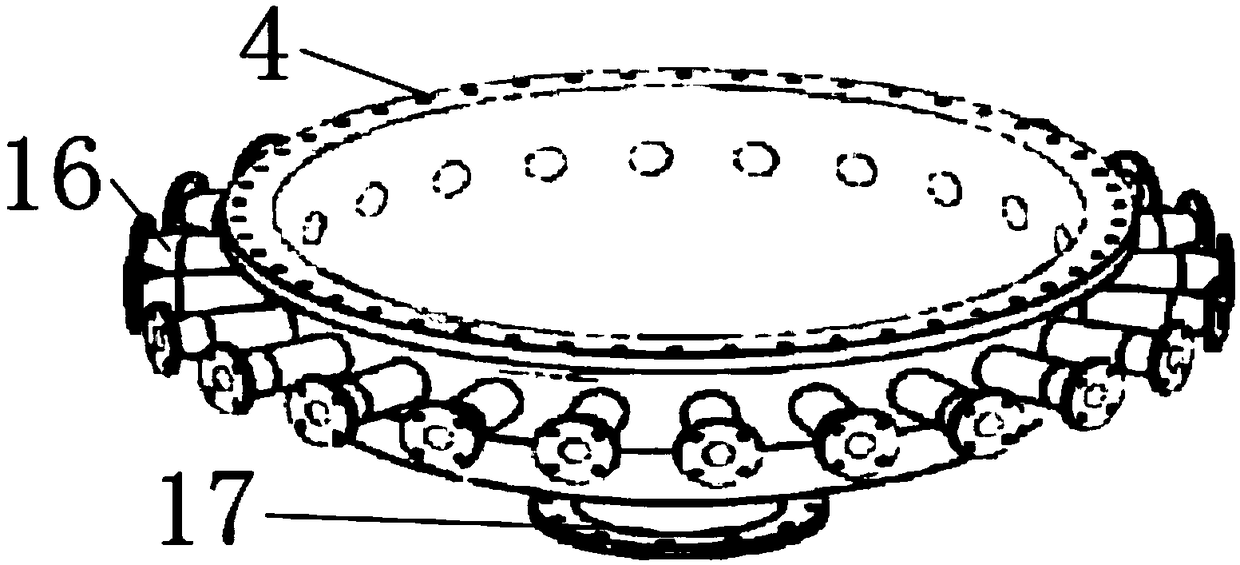

[0026] Such as Figure 1-10 As shown, this specific embodiment adopts the following technical solutions: the energy-saving cyclone includes a fixed plate 1, a protective shell 2 is welded in the middle of the lower end of the fixed plate 1, and an overflow groove 8 is welded on the outside of the protective shell 2, A grit chamber 10 is welded on the outside of the overflow tank 8, a fence 6 is welded around the upper end of the fixed plate 1, and a distributor 3 is welded in the middle of the upper end of the fixed plate 1, and the distributor 3 includes a casing 4 , the outer periphery of the shell 4 is welded with several conduits 16, the distance between two adjacent conduits 16 is the same, the upper end of the shell 4 is welded with a distributor cover 5, the upper end of the distributor cover 5 A number of pressure interface flanges 13 are welded, and a number of valve bodies 7 composed of manual valves and solenoid valves are arranged on one side of the distributor 3. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com