Cooling and spraying system of forging press of annular forging blank

A technology of ring forgings and forging presses, which is applied in the field of forging presses, can solve problems such as easy adhesion and mold damage, and achieve the effect of ensuring service life and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

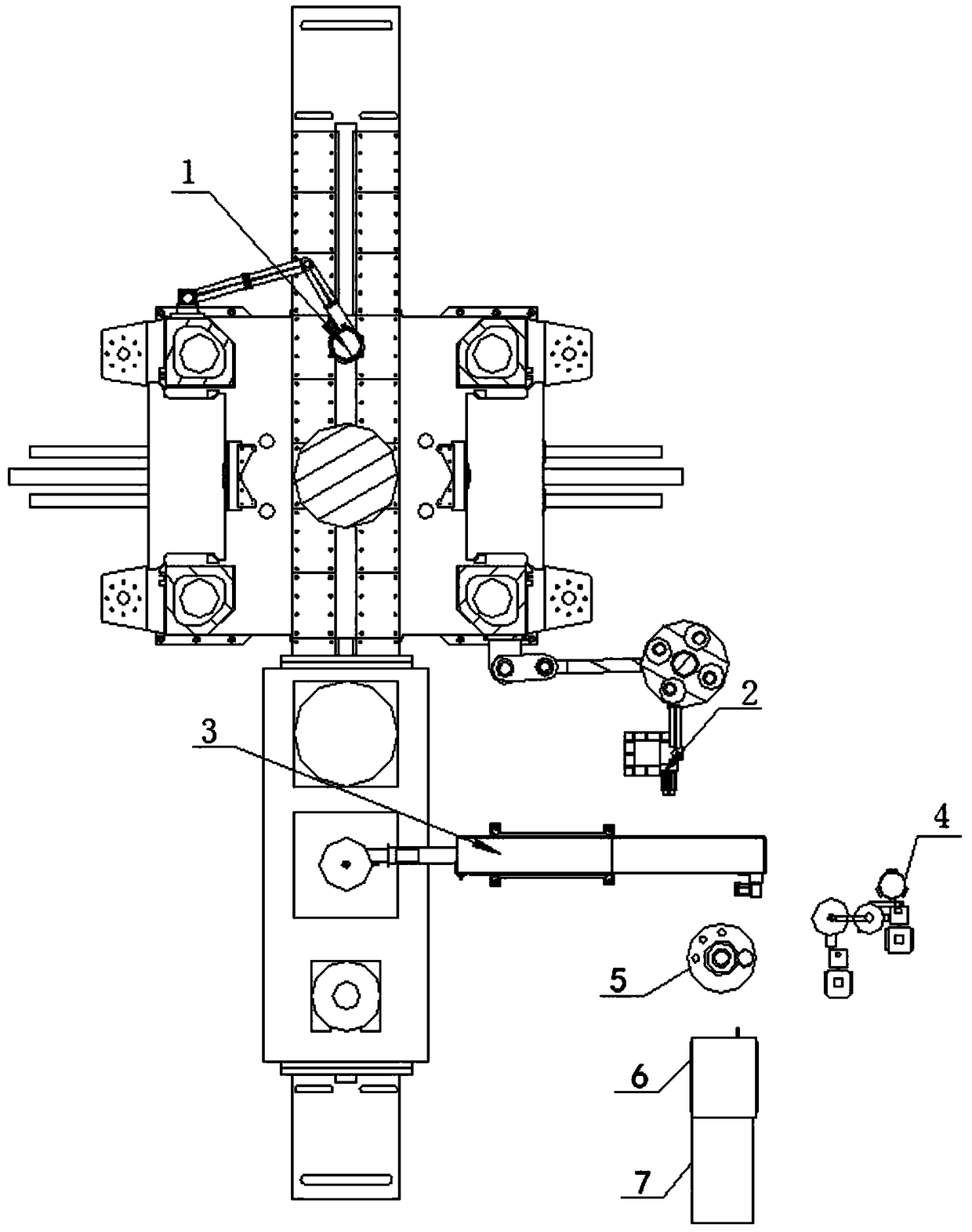

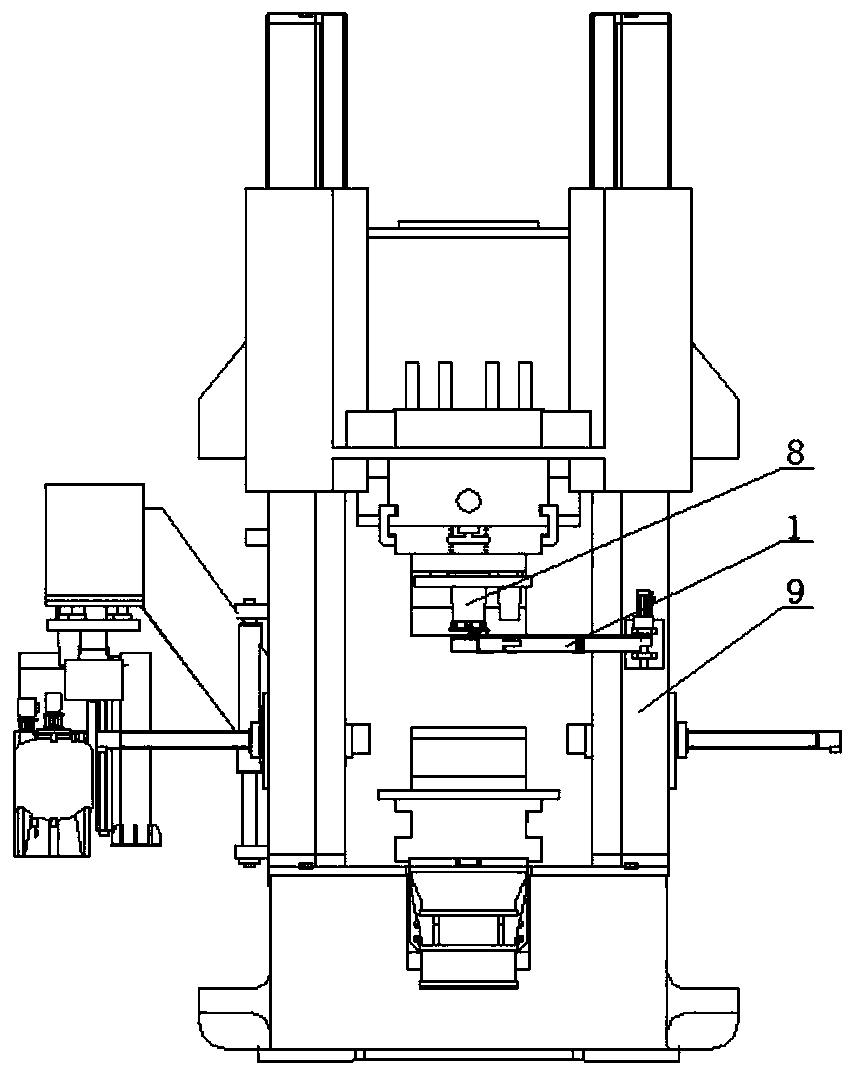

[0020] A ring forging billet forging machine cooling spraying system, such as figure 1 As shown, it includes a positioning punch cooling spray device 1, a punching punch cooling spray device 3, a forming punch cooling spray device 2, a cooling water circulation system 4 connected to the above spraying devices, and a release agent delivery constant pressure delivery system. 6. Release agent storage tank 5 and automatic control system 7.

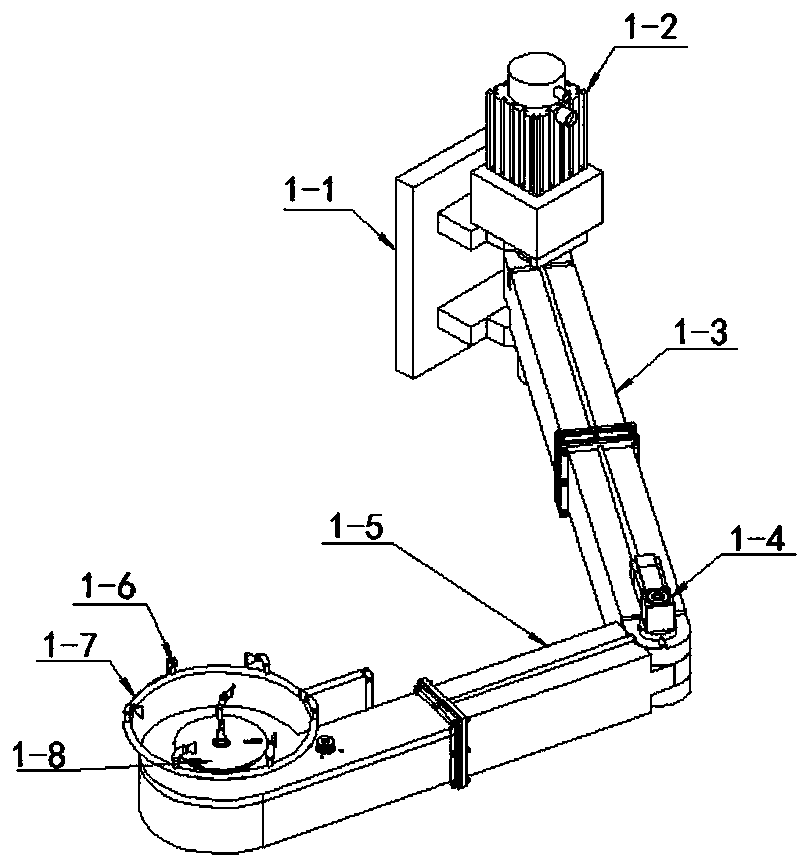

[0021] The positioning punch cooling spraying device, such as figure 2 As shown, it includes the rotating arm support seat 1-1, the first rotating arm 1-3, the second rotating arm 1-5, the positioning punch rotary sprayer 1-8, the positioning punch cooling water sp...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap