Operation platform for cooker panel machining

A panel processing and operating table technology, applied in workbenches, manufacturing tools, etc., can solve the problems of reduced processing quality, small application range, deviation, etc., to achieve direct and effective force transmission, uniform and stable push-pull force, and improved stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

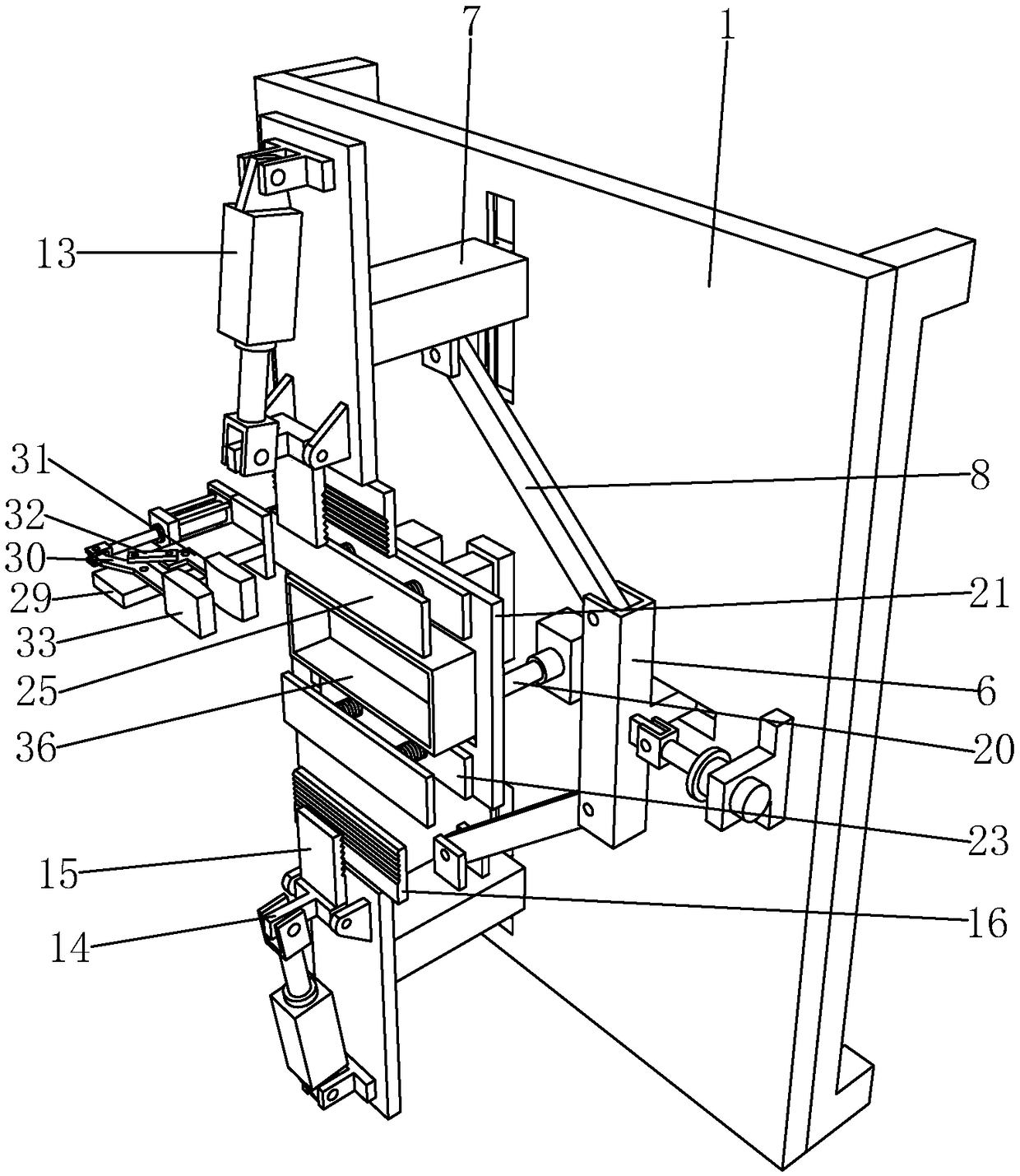

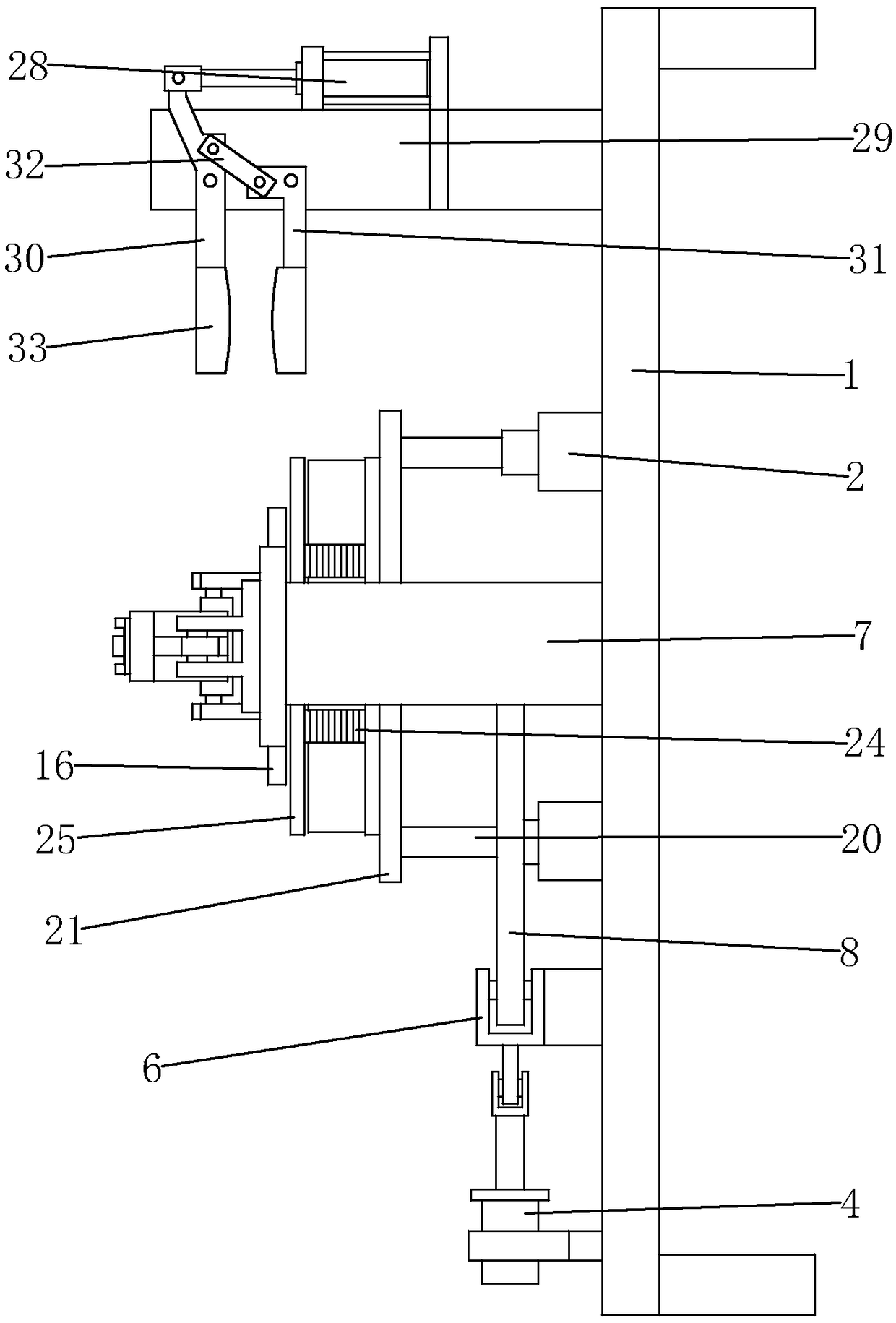

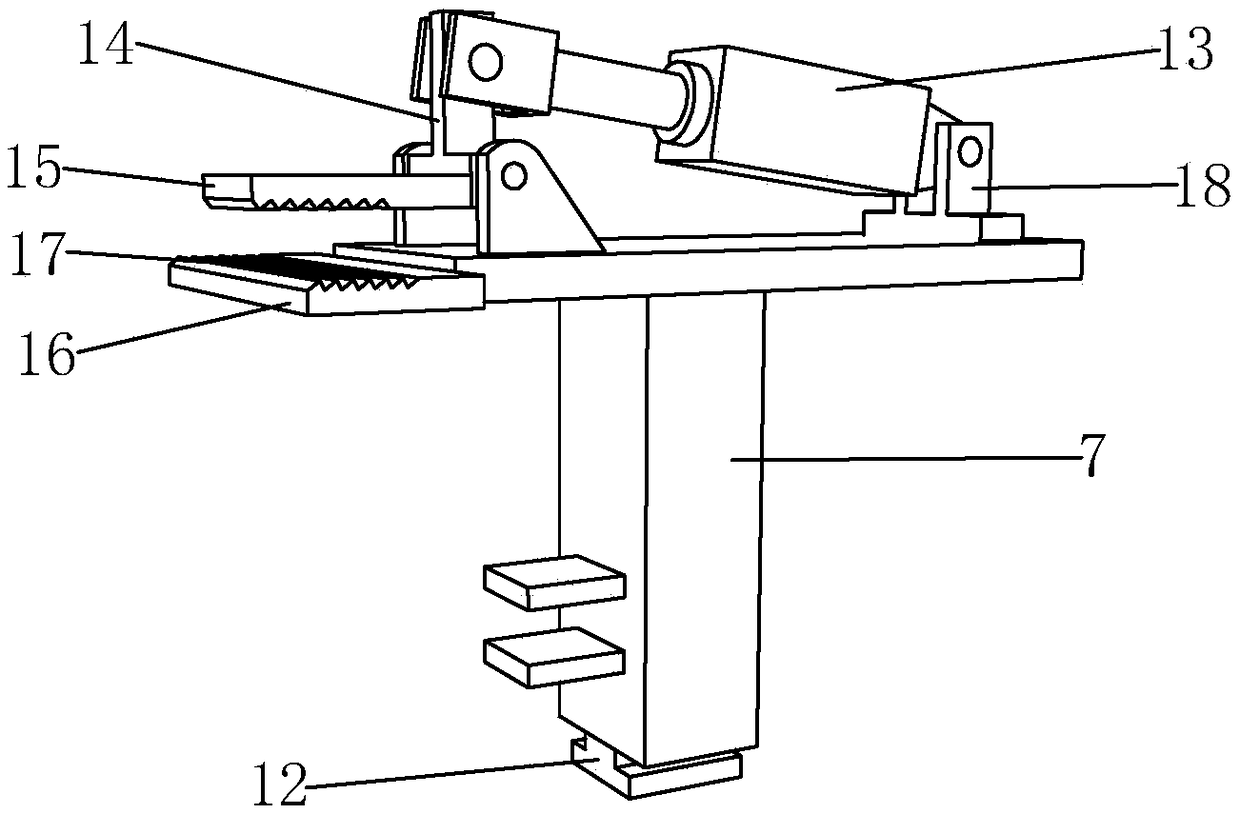

[0025] Such as Figure 1 to Figure 7 As shown in the figure, it is an operation table for processing cooker panels according to the present invention, including a workbench 1, on which a push mechanism, a support base 2 and a stroke cylinder 3 are arranged, and the push mechanism includes a push cylinder 4 and a piston push rod 5. The push cylinder 4 is connected to the piston push rod 5, and the push cylinder 4 is set on the workbench 1. One end of the piston push rod 5 is connected to a U-shaped slide plate 6, and the workbench 1 is slidably connected to a stand 7, which is connected to the U-shaped slide. There is a transmission rod 8 between the U-shaped skateboards 6, and the vertical frames 7 are symmetrically distributed, and the cylinder 4 is pushed to drive the piston push rod 5 to perform telescopic movement, thereby driving the U-shaped skateboard 6 to slide back and forth, and flexibly adjust the distance between the two vertical frames 7. Therefore, it is applicab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com