Hybrid power coupled axle based on two gearboxes

A hybrid power and gearbox technology, applied in the field of coupling bridge structure, can solve the problem that the coupling bridge cannot be applied, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

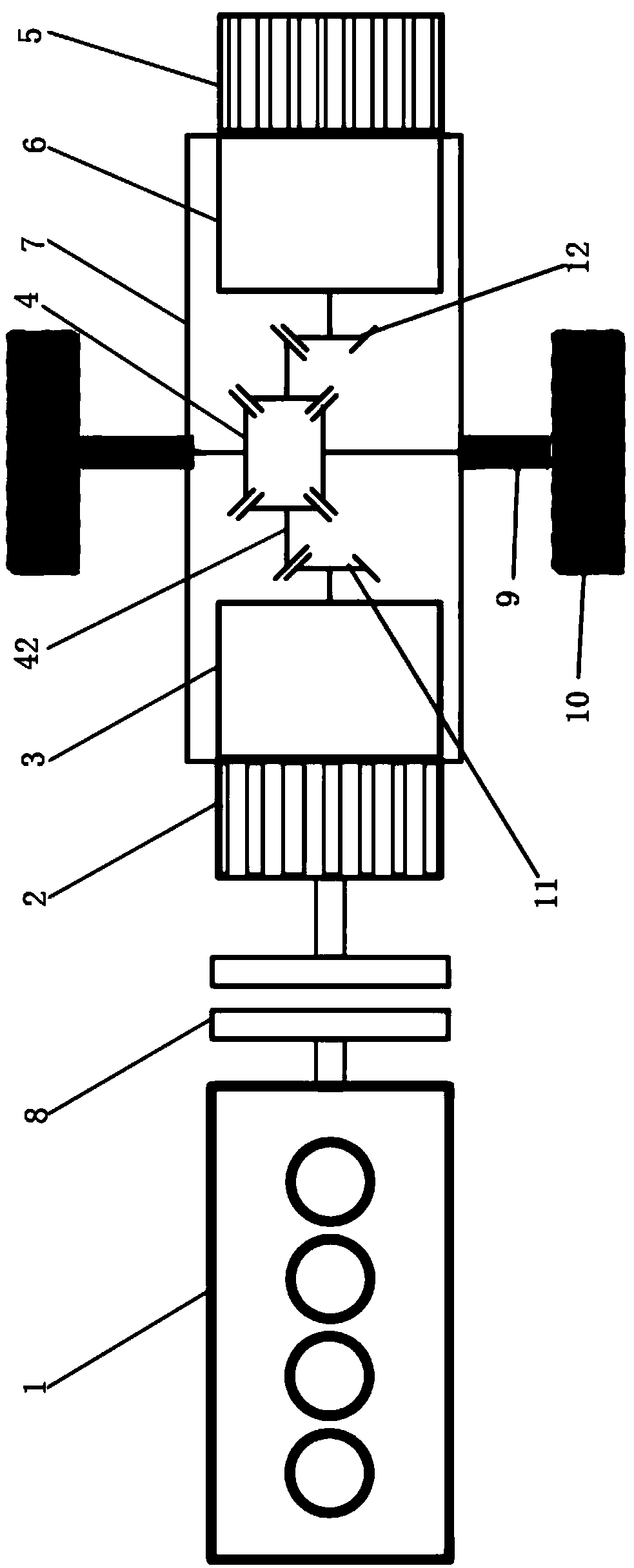

[0017] Specific embodiment one, see figure 1 : the output shaft of the engine 1, the transmission shaft of the clutch 8, and the motor shaft of the first motor 2 are coaxially arranged respectively, the engine 1, the clutch 8, and the first motor 2 are connected in sequence, and the output end of the motor shaft of the first motor 2 Connect the input end of the first gearbox 3, the output shaft of the first gearbox 3 meshes with the main reducer bevel gear 42 of the differential 4 through the first bevel gear 11, and the output shaft of the second gearbox 6 passes through the second bevel gear 12 Mesh and connect the main reducer bevel gear 42 of the differential 4, the first motor 2 and the second motor 5 are respectively arranged on both sides of the same horizontal plane of the differential 4, the motor shafts of the first motor 2 and the second motor 5 Set on the extension line of the same axis.

specific Embodiment 2

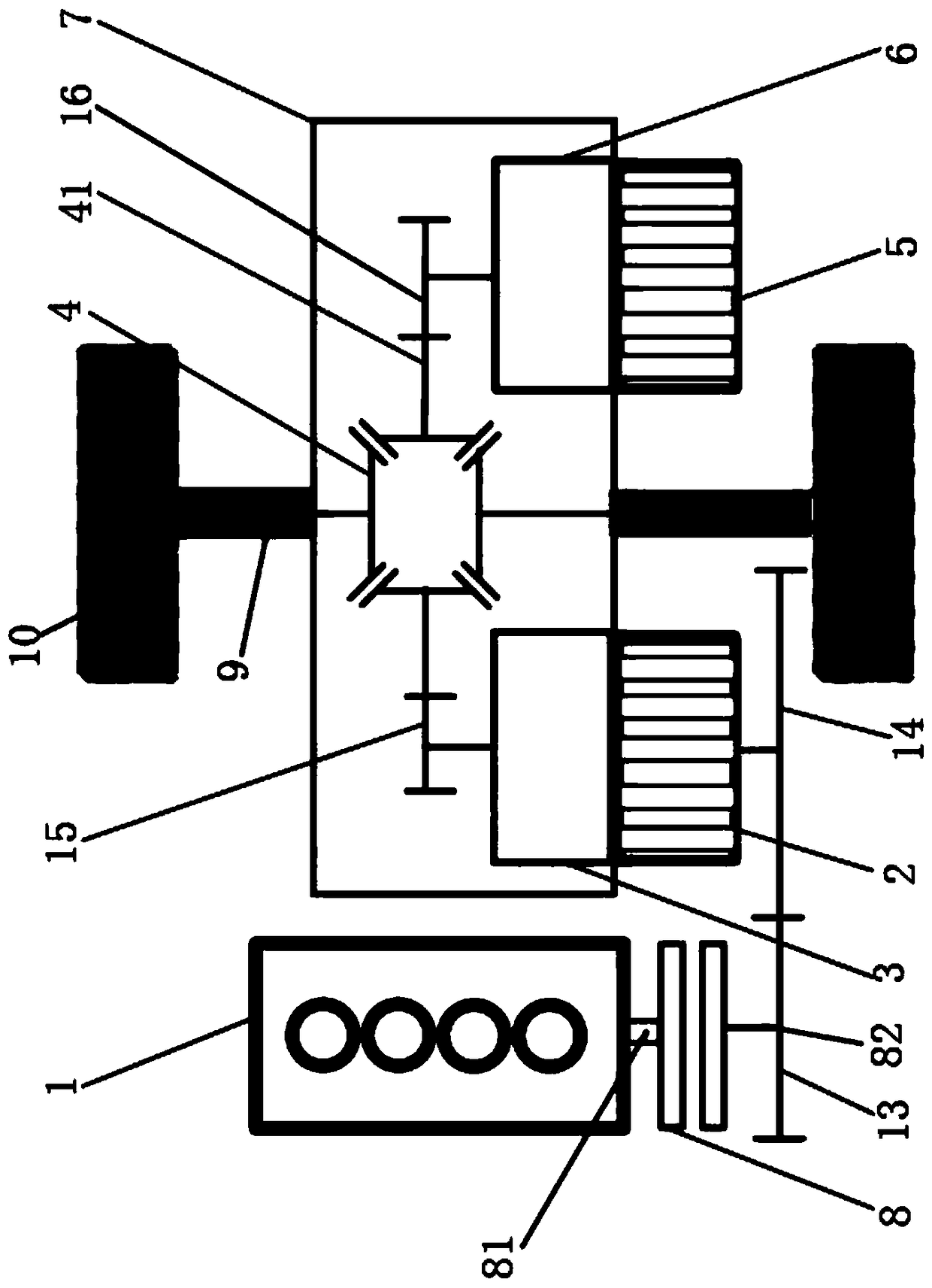

[0018] Specific embodiment two, see figure 2 : the output shaft of the engine 1 is arranged parallel to the half shaft 9, the output shaft of the engine 1 is connected to the first transmission shaft 81 of the clutch 8, the second transmission shaft 82 of the clutch 8 is connected with the first transmission gear 13, and the first transmission gear 13 meshes Connect the second transmission gear 14, the central axis of the second transmission gear 14 is connected to the input end of the motor shaft of the first motor 2, the output end of the motor shaft of the first motor 2 is connected to the input end of the first gearbox 6, the first speed change The output end of the box 3 is equipped with a third transmission gear 15, the third transmission gear 15 is meshed with the main reduction gear 41, and the output end of the second gearbox 6 is equipped with a fourth transmission gear 16, and the fourth transmission gear 16 is meshed with the main reduction gear 41. The main reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com