Continuous assembly process of automobile chassis mixed line

A technology of automobile chassis and assembly process, which is applied in the direction of motor vehicles, transportation and packaging, etc. It can solve problems such as waste, missing or wrong assembly, and affect product quality, and achieve the effect of reasonable process design and reduced labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

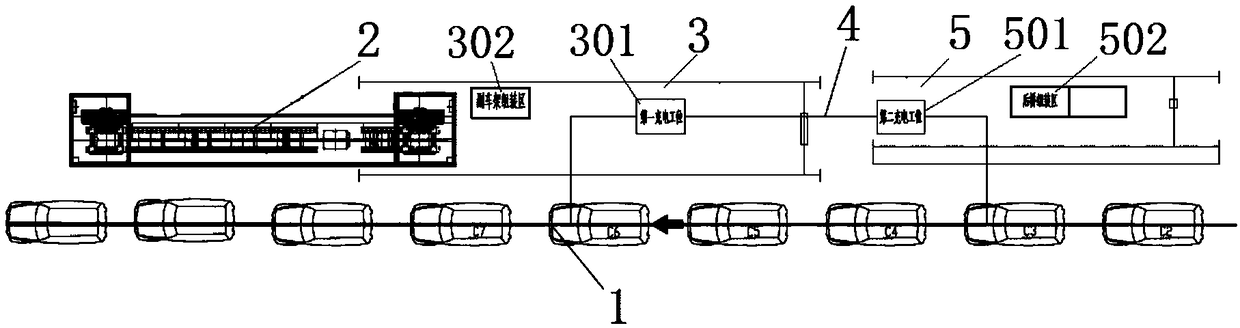

[0020] like figure 1 Shown, the preferred specific example of the present invention is:

[0021] Use a single-lift AGV to complete the assembly of chassis components for gasoline vehicles and pure electric vehicles. There are five main components. The engine, gearbox and front axle are one component, the rear axle is one component, and the motor, gearbox and front bracket are one component. , the battery is a component, and the rear axle of an electric vehicle is a component. Gasoline vehicles have two components, and pure electric vehicles have three components. Six single-lift AGV electric vehicles are selected to work, which can meet the continuous chassis assembly work of mixed lines.

[0022] The process system work design is:

[0023] The AGV electric vehicle has five items that enter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com