Semi-automatic compressor slip sheet packing device and packing method

A compressor and semi-automatic technology, applied in the directions of automatic packaging control, packaging, packaging protection, etc., can solve the problems of manpower and material resources, low efficiency of compressor slides, poor classification accuracy, etc., and achieve the effect of low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

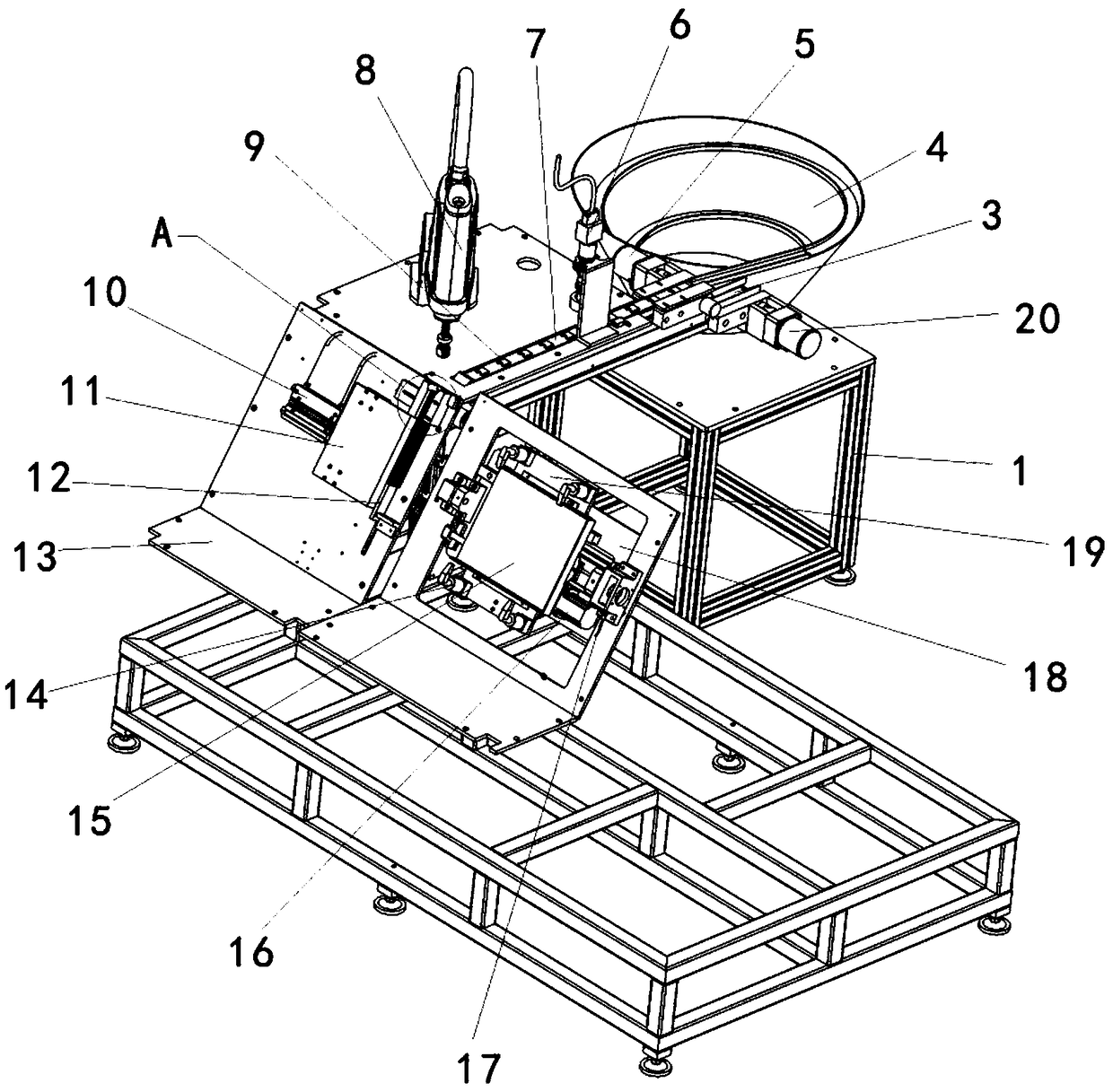

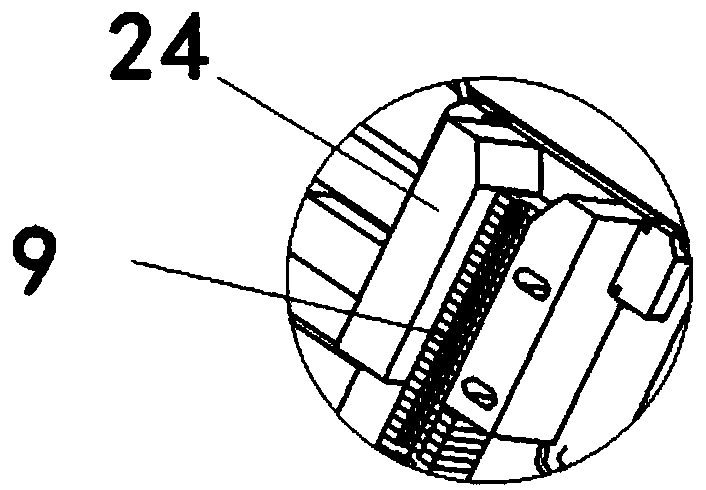

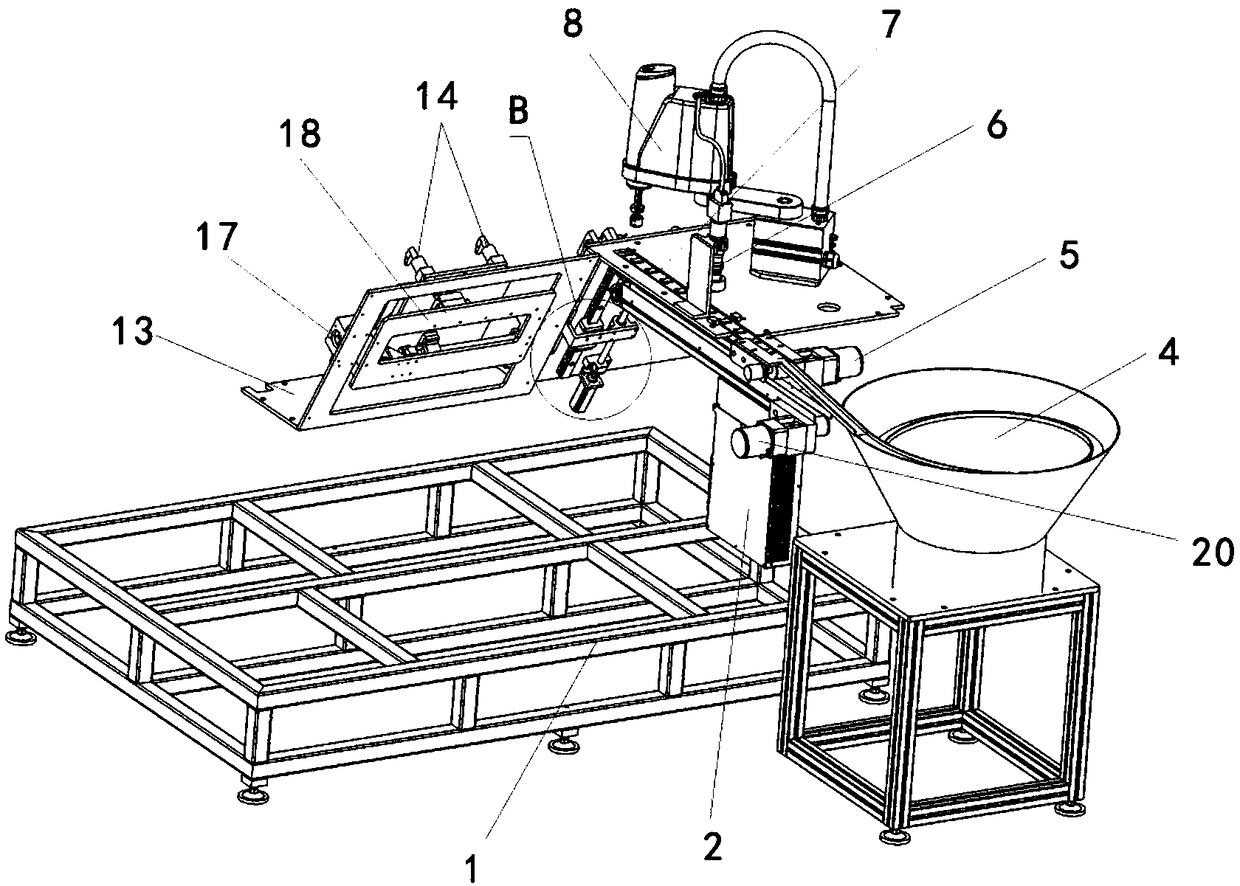

[0017] Embodiment of the present invention: the structural diagram of the semi-automatic compressor sliding vane boxing device and the boxing method is as follows Figure 1~4 As shown, it includes a frame 1 and a controller 2, a vibrating pot 4 and an integrated mounting plate 13 respectively installed on the frame 1, and a feeding conveyor belt 7 is installed on the top of the integrated mounting plate 13, and the output of the vibrating pot 4 The track is docked with the feed conveyor belt 7, and the feed conveyor belt 7 is driven by the feed motor 5; a manipulator 8 and a camera 6 are respectively fixedly installed on both sides of the feed conveyor belt 7, and the camera 6 is positioned on the side of the feed conveyor belt 7 Directly above, o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com