Hydrotalcite and its preparation method

A technology of hydrotalcite and calcium chloride, which is applied in chemical instruments and methods, manganese compounds, inorganic chemistry, etc., and can solve problems such as the lack of preparation methods for hydrotalcite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

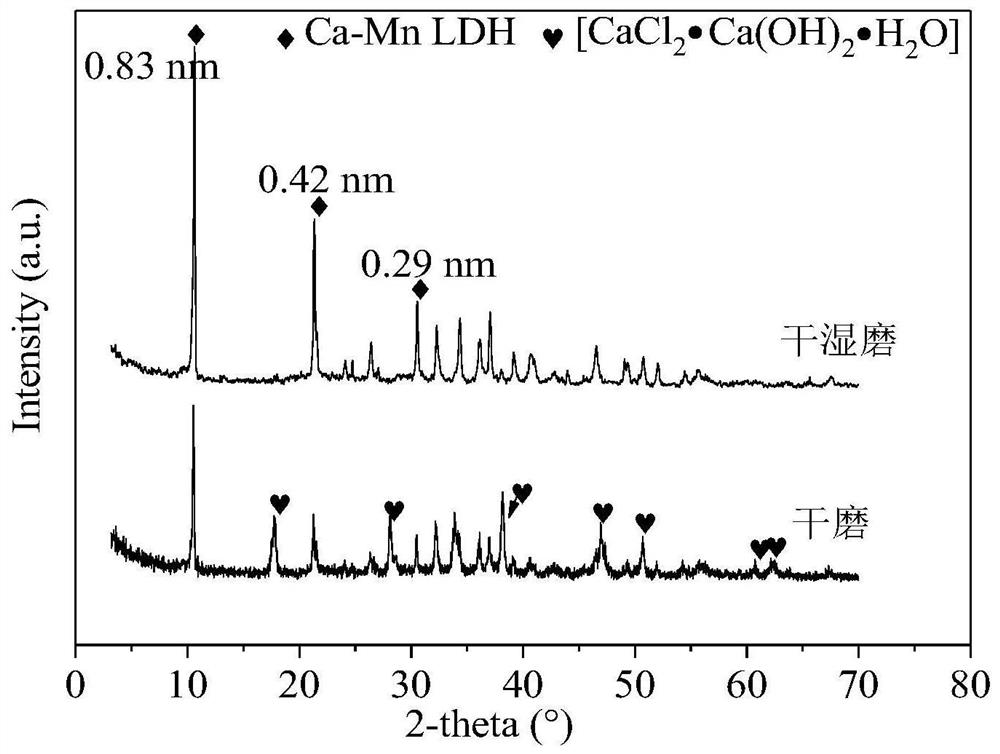

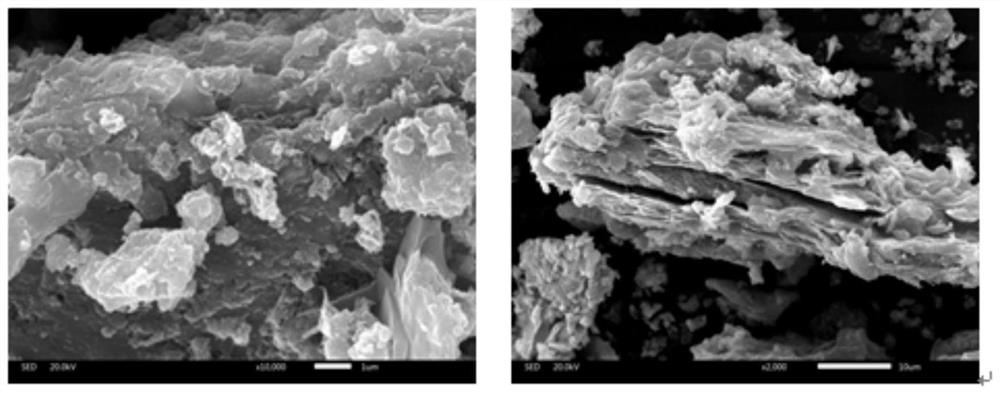

[0023]Some embodiments of the present invention improve a preparation method of hydrotalcite, which includes:

[0024]The raw materials of synthetic hydrotalcite are dry-milled, and the basic structure of hydrotalcite is formed through solid-phase chemical reaction. The raw materials include metal hydroxides, high-valent metal oxides and metal salts.

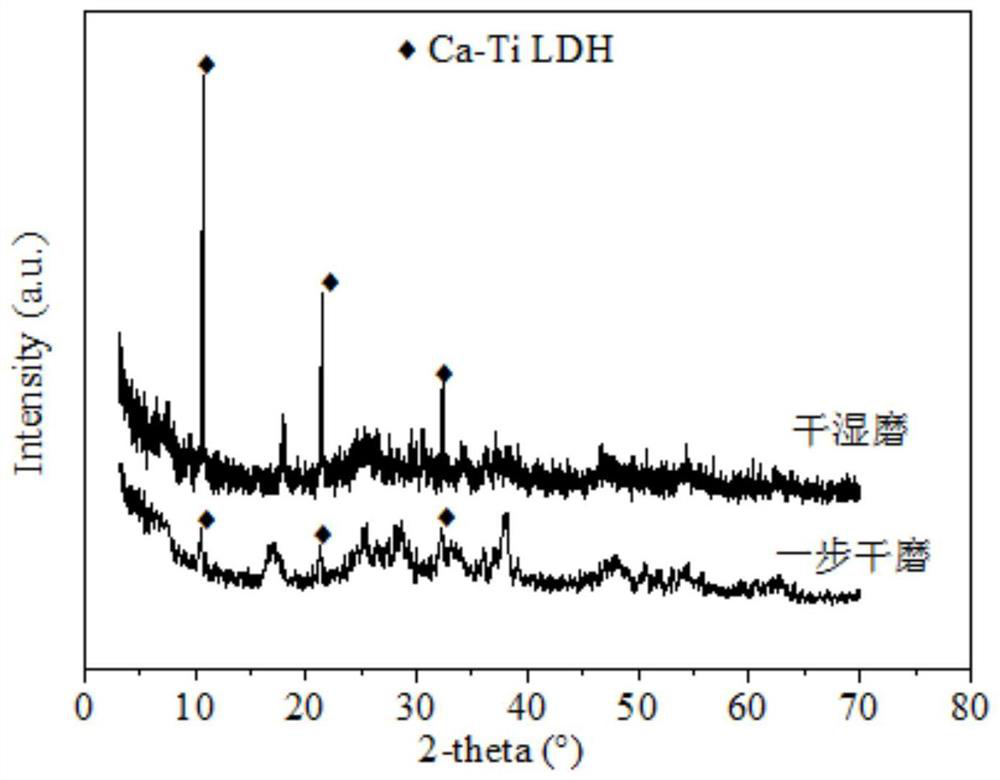

[0025]The inventor found that in the prior art, liquid phase co-precipitation is usually used to form a hydrotalcite phase, where the metal ion Mg2+, Zn2+, Cu2+And Co2+It can co-precipitate with tetravalent metals (Ti, Sn, etc.) in liquid phase to form LDH phase, while Ca2+However, it is difficult to achieve. The inventors have discovered through a lot of research that the reason why calcium ions cannot co-precipitate with tetravalent metals to form LDH phase may be: on the one hand, Ca2+The precipitation pH is higher (pH>12 begins to precipitate), while the pH value of the tetravalent metal ion precipitation is low, it is difficult for the...

Embodiment 1

[0044]This embodiment provides a method for preparing Ca-Ti hydrotalcite, which includes the following steps:

[0045]The total mass of 2g Ca(OH)2, CaCl2·2H2O and TiO2·H2O was added to the ball mill, the ball-to-material ratio was 25, the ball-mill speed was controlled to 600rpm, and the dry-type ball-milling material was 2h, of which Ca(OH)2, CaCl2·2H2O and TiO2·H2The molar ratio of O is 3:1:1.5.

Embodiment 2

[0047]This embodiment provides a method for preparing Ca-Ti hydrotalcite, which includes the following steps:

[0048]The total mass of 2g Ca(OH)2, CaCl2·2H2O and TiO2·H2O was added to the ball mill, the ball-to-material ratio was 25, the ball-mill speed was controlled to 600rpm, and the dry-type ball-milling material was 2h, of which Ca(OH)2, CaCl2·2H2O and TiO2·H2The molar ratio of O is 3:1:1.8.

[0049]Then add 0.3 mL of water, control the ball-to-battery ratio and rotating speed unchanged, and perform wet grinding for 1 hour to obtain agglomerated hydrotalcite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com