Hydrotalcite and preparation method thereof

A hydrotalcite and metal technology, applied in chemical instruments and methods, inorganic chemistry, titanium compounds, etc., can solve problems such as the lack of hydrotalcite preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] Some embodiments of the present invention improve a preparation method of hydrotalcite, comprising:

[0024] The raw materials for synthesizing hydrotalcite are dry-milled, and the basic structure of hydrotalcite is formed through solid-phase chemical reaction, wherein the raw materials include metal hydroxides, high-valent metal oxides and metal salts.

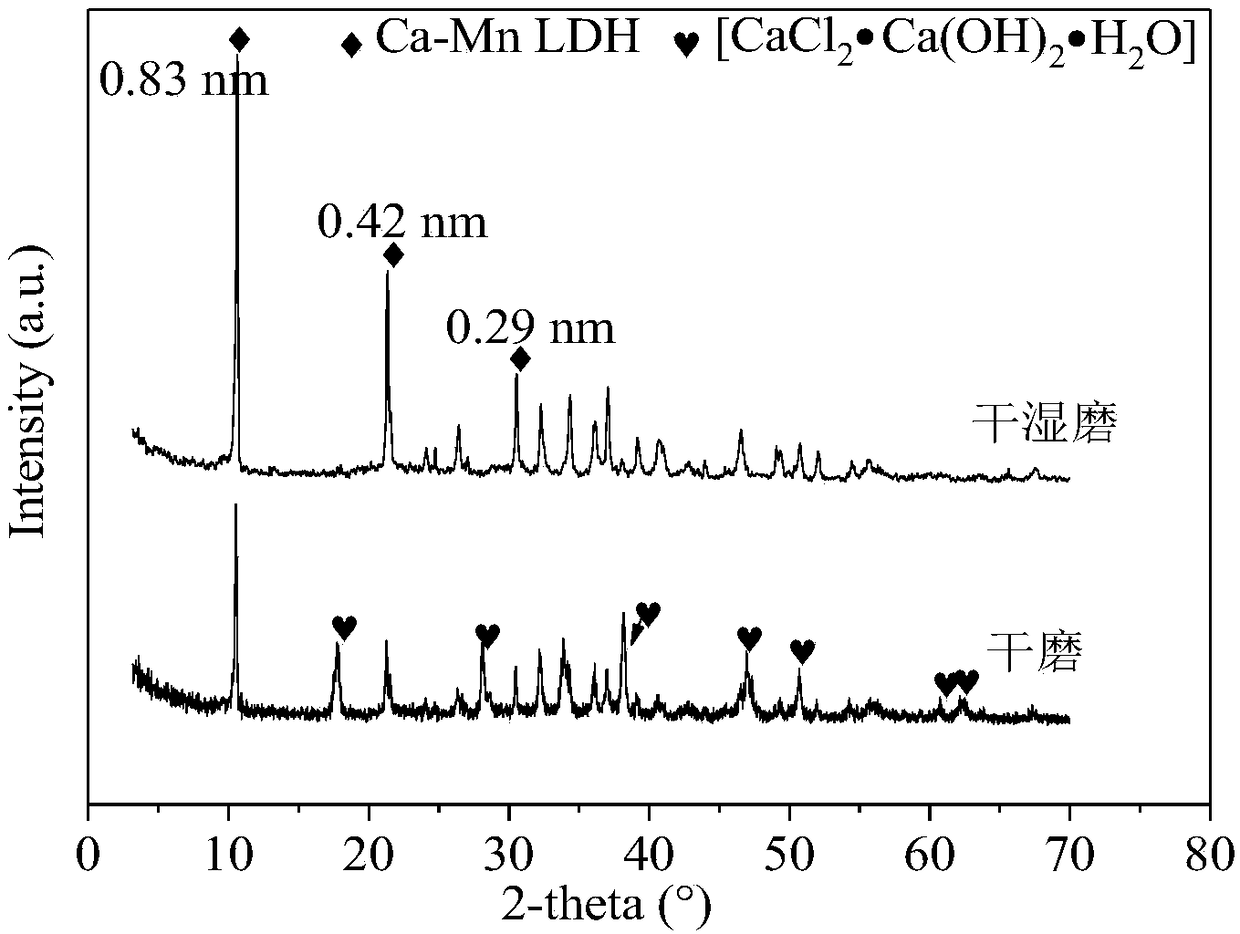

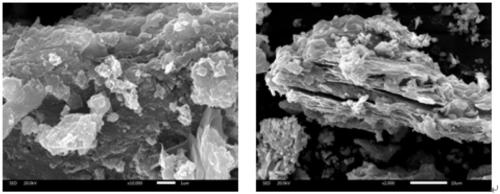

[0025] The inventors found that in the prior art, liquid phase co-precipitation is usually used to form a hydrotalcite phase, wherein the metal ion Mg 2+ , Zn 2+ , Cu 2+ and Co 2+ It can co-precipitate with tetravalent metals (Ti, Sn, etc.) in liquid phase to form LDH phase, while Ca 2+ However, it is difficult to achieve. After a lot of research, the inventor found that the reason why calcium ions cannot co-precipitate with tetravalent metals to form LDH phase may be: on the one hand, Ca 2+ The pH value of precipitation is high (pH>12 starts to precipitate), while the pH value of tetravalent metal ion precipitatio...

Embodiment 1

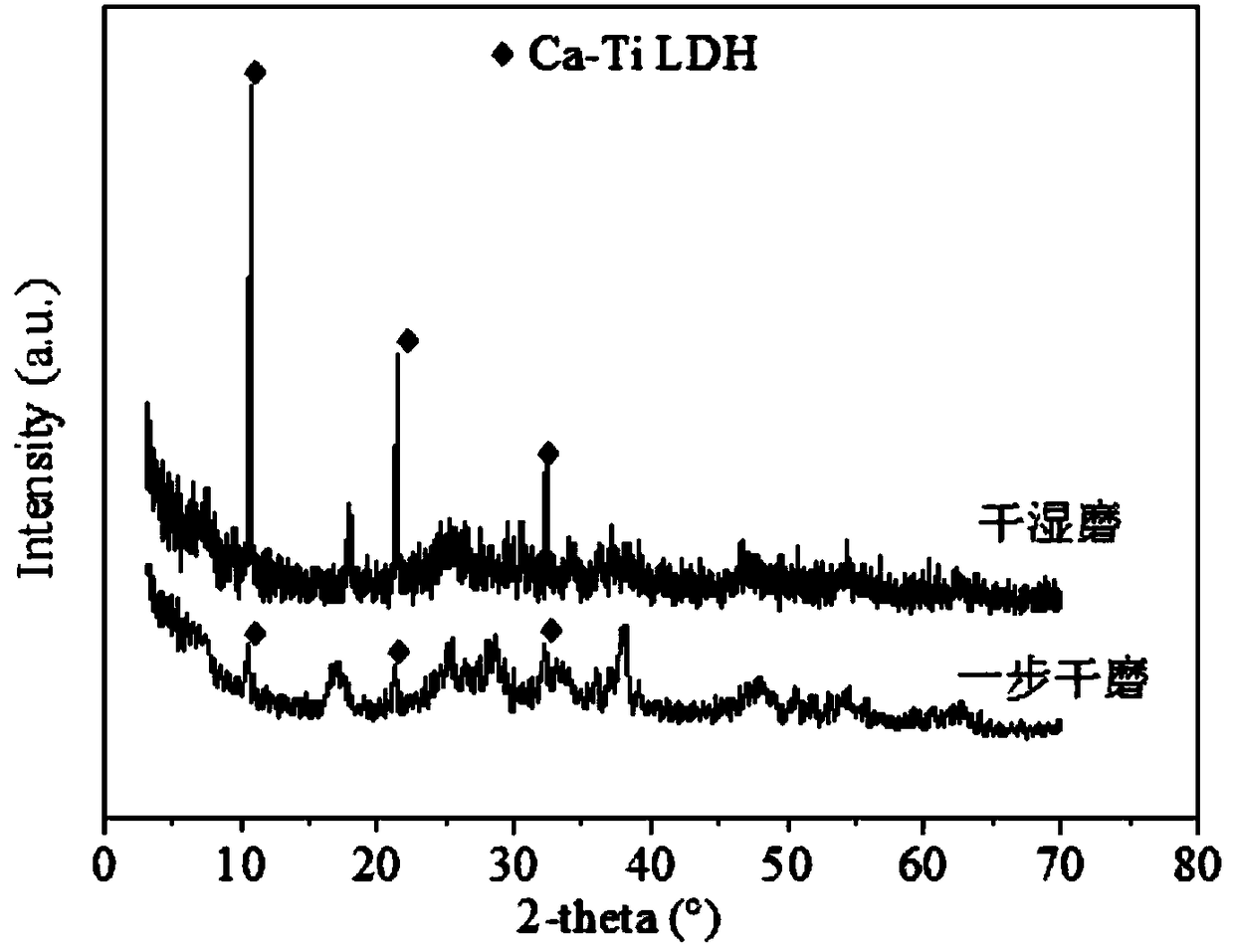

[0044] The present embodiment provides a preparation method of Ca-Ti based hydrotalcite, which comprises the following steps:

[0045] The total mass of Ca(OH) is 2 g 2 , CaCl 2 ·2H 2 O and TiO 2 ·H 2 O was added to the ball mill, the ball-to-material ratio was 25, the ball mill rotation speed was controlled to 600rpm, and the dry ball milled material was 2h, wherein Ca(OH) 2 , CaCl 2 ·2H 2 O and TiO 2 ·H 2 The molar ratio of O is 3:1:1.5.

Embodiment 2

[0047] The present embodiment provides a preparation method of Ca-Ti based hydrotalcite, which comprises the following steps:

[0048] The total mass of Ca(OH) is 2 g 2 , CaCl 2 ·2H 2 O and TiO 2 ·H 2 O was added to the ball mill, the ball-to-material ratio was 25, the ball mill rotation speed was controlled to 600rpm, and the dry ball milled material was 2h, wherein Ca(OH) 2 , CaCl 2 ·2H 2 O and TiO 2 ·H 2 The molar ratio of O is 3:1:1.8.

[0049] Then 0.3 mL of water was added, and the ball-to-material ratio and rotational speed were controlled to remain unchanged, and wet grinding was carried out for 1 h to obtain agglomerated hydrotalcite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com