Uniform dispersion method of sintering aid and application of the sintering aid in this method

A sintering aid, uniform dispersion technology, applied in the field of dielectric materials, can solve the problems of excessive sintering aid addition, residue, uneven addition, etc., and achieve the effect of avoiding negative effects and reducing residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Ce oxide doped with samarium 0.8 SM 0.2 o 1.9 For example, take 1mol of Ce 0.8 SM 0.2 o 1.9 The powder is a sintered experimental sample, and by calculation, Ce 0.8 SM 0.2 o 1.9 The powder mass is 172.56g. The sintering performance of the powder without adding sintering aids is: after sintering at 1300°C for 5 hours, the relative density reaches 92%.

[0021] In order to highlight the beneficial effects of the present invention, use the technical solution proposed by the present invention to do the following operations.

[0022] (1) Take 1mol of Ce 0.8 SM 0.2 o 1.9 The powder is a sintered experimental sample, and by calculation, Ce 0.8 SM 0.2 o 1.9 The powder mass is 172.56g.

[0023] (2) Take 0.00001mol, Ba(NO 3 ) 2 As a sintering aid, dissolve in 500ml deionized water.

[0024] (3) the Ce in the above (1) 0.8 SM 0.2 o 1.9 Powder and Ba(NO in (2) 3 ) 2 The solution is mixed.

[0025] (4) Take 5g of weight (NH 4 ) 2 CO 3 , dissolved in 100ml ...

Embodiment 2

[0031] (1) Take 1 mol of Ce 0.8 Sm 0.2 O 1.9 The powder is a sintered experimental sample. By calculation, Ce 0.8 Sm 0.2 O 1.9 The powder mass was 172.56g.

[0032] (2) Take 0.00005 mol of Ba(NO) with a mass of 13.0 mg 3 ) 2 As a sintering aid, dissolved in 500ml of deionized water.

[0033] (3) Ce in the above (1) 0.8 Sm 0.2 O 1.9 Powder and Ba(NO in (2) 3 ) 2 Solution mix.

[0034] (4) Take 5g of (NH 4 ) 2 CO 3 , dissolved in 100ml of deionized water.

[0035] (5) The (NH) in the above (4) 4 ) 2 CO 3 The solution is added to the mixed system in (3), and the Ba ion reacts with carbonate to form a precipitate, which is attached to the Ce 0.8 Sm 0.2 O 1.9 surface or dispersed in Ce 0.8 Sm 0.2 O 1.9 middle of the powder. During this process, the Ba ions in the above (2) solution will be transformed from the solution phase to solid phase particles, which are uniformly dispersed in the entire system.

[0036] (6) The mixed system in the above (5) was cen...

Embodiment 3

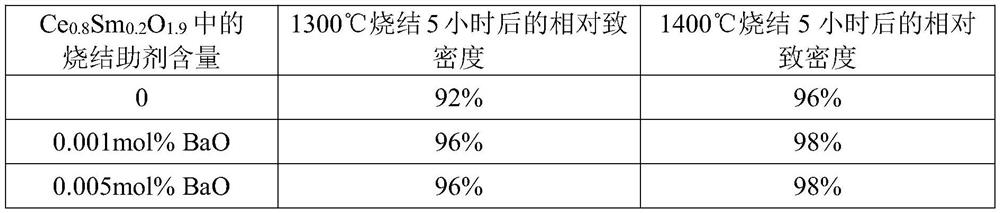

[0040] With 0.001-0.005mol% of BaO as sintering aid, added to Ce 0.8 Sm 0.2 O 1.9 Among them, the following data are obtained through experiments, indicating that the use of the BaO sintering aid of 0.001-0.005 mol% disclosed in the present invention can improve the sintering performance of the doped ceria material, Ce 0.8 Sm 0.2 O 1.9 The sintering temperature was lowered by 100 °C.

[0041]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com