A kind of printed top layer leather and its processing technology

A processing technology and top leather technology, which is applied in the field of printed top leather and its processing technology, can solve problems such as the failure of top leather to be embossed and the decline in the quality of top leather products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

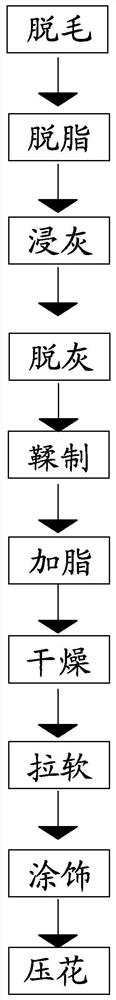

[0066] Such as Figure 1-20 As shown, a processing technology of antique top layer leather, wherein, the antique top layer leather is processed through the steps of depilation, degreasing, liming, deliming, tanning, fatliquoring, drying, softening, painting and embossing ;

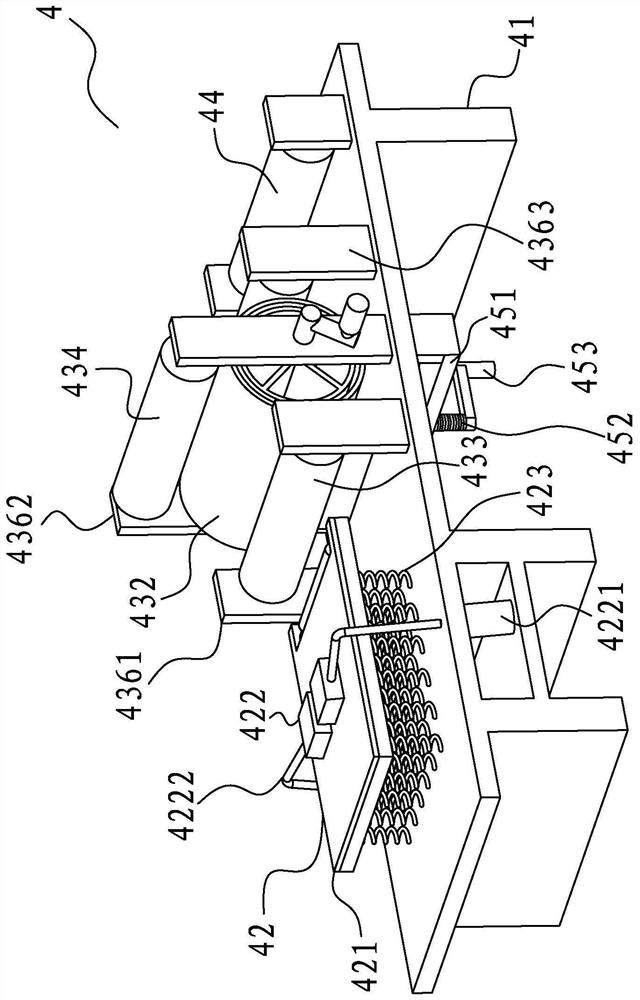

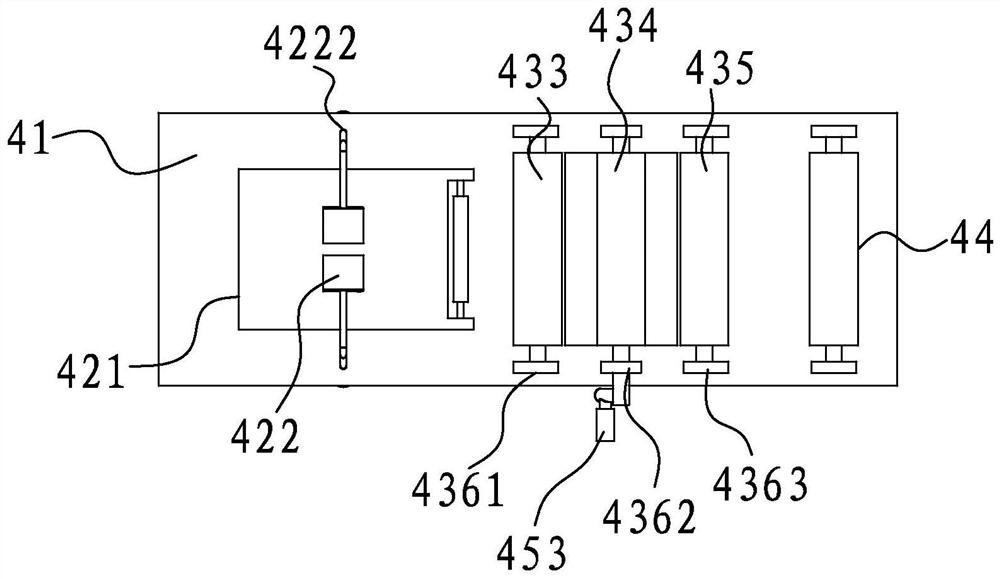

[0067] In the embossing step, the top layer leather is embossed through the embossing machine 4, in order to allow the top layer leather to be embossed more effectively to obtain a better embossing effect. Therefore, described embossing machine 4 comprises embossing frame 41, flattening device 42, embossing device and cooling roll 44, and described flattening device 42, embossing device and cooling roll 44 are arranged on embossing frame 41 successively by processing sequence, head The skin is smoothed, embossed and cooled in sequence; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com