Textile cloth soaking and collecting equipment

A technology for textile fabrics and equipment, which is applied in the field of textile fabric soaking and collecting equipment, can solve the problems of affecting the cloth collecting process and the inability to flatten the cloth, and achieve the effects of reducing labor intensity, facilitating the collecting of fabrics, and eliminating wrinkles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

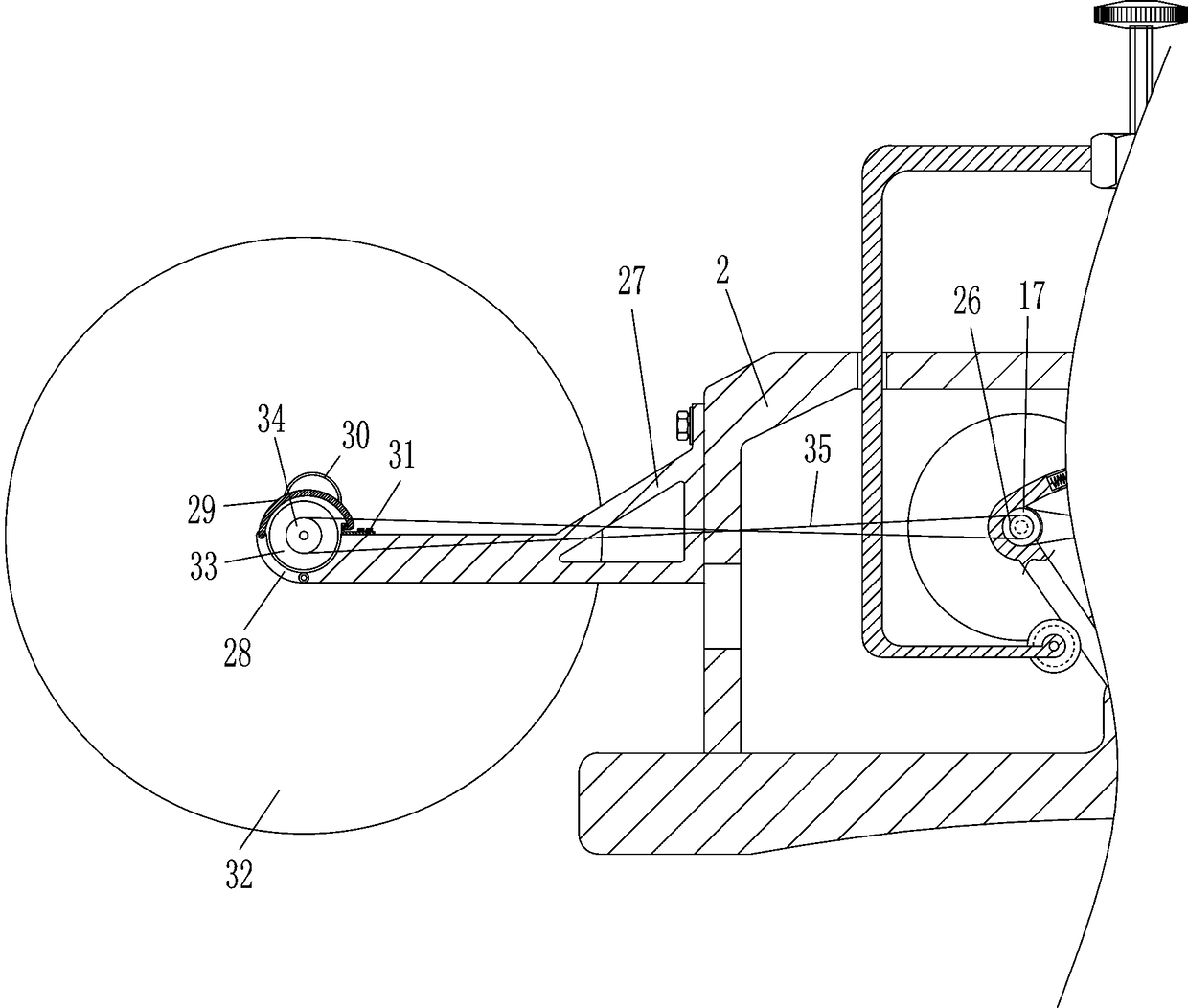

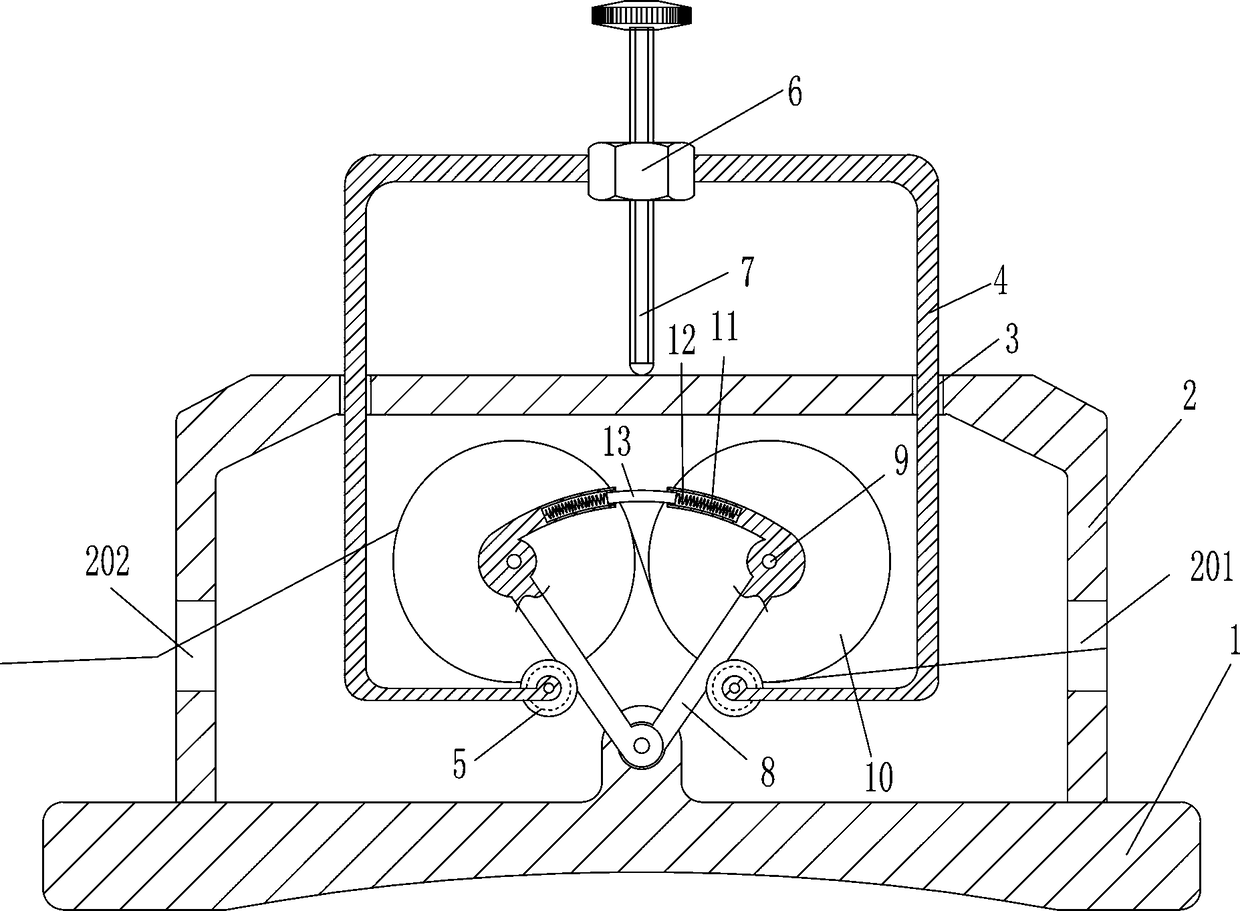

[0016] A kind of soaking and collecting equipment for textile cloth, such as figure 1 As shown, it includes a support 1, a first bracket 2, a first guide rod 4, a first roller 5, a nut 6, a screw 7, a first swing rod 8, a first rotating shaft 9, a squeeze wheel 10, a first spring 12 and an arc-shaped slide bar 13, the top of the support 1 is connected with the first support 2, the support 1 is connected with the first support 2 by means of bolts, and the middle part of the right side of the first support 2 has a first feed port 201, The middle part on the left side of the first bracket 2 is provided with a second feeding port 202, and the left and right sides of the top of the first bracket 2 are provided with first guide holes 3, and the first guide holes 3 on the left and right sides are movable and provided with first guide holes. Rod 4, a nut 6 is embedded in the middle of the top of the first guide rod 4, a screw rod 7 is provided in the nut 6 in a threaded manner, first ...

Embodiment 2

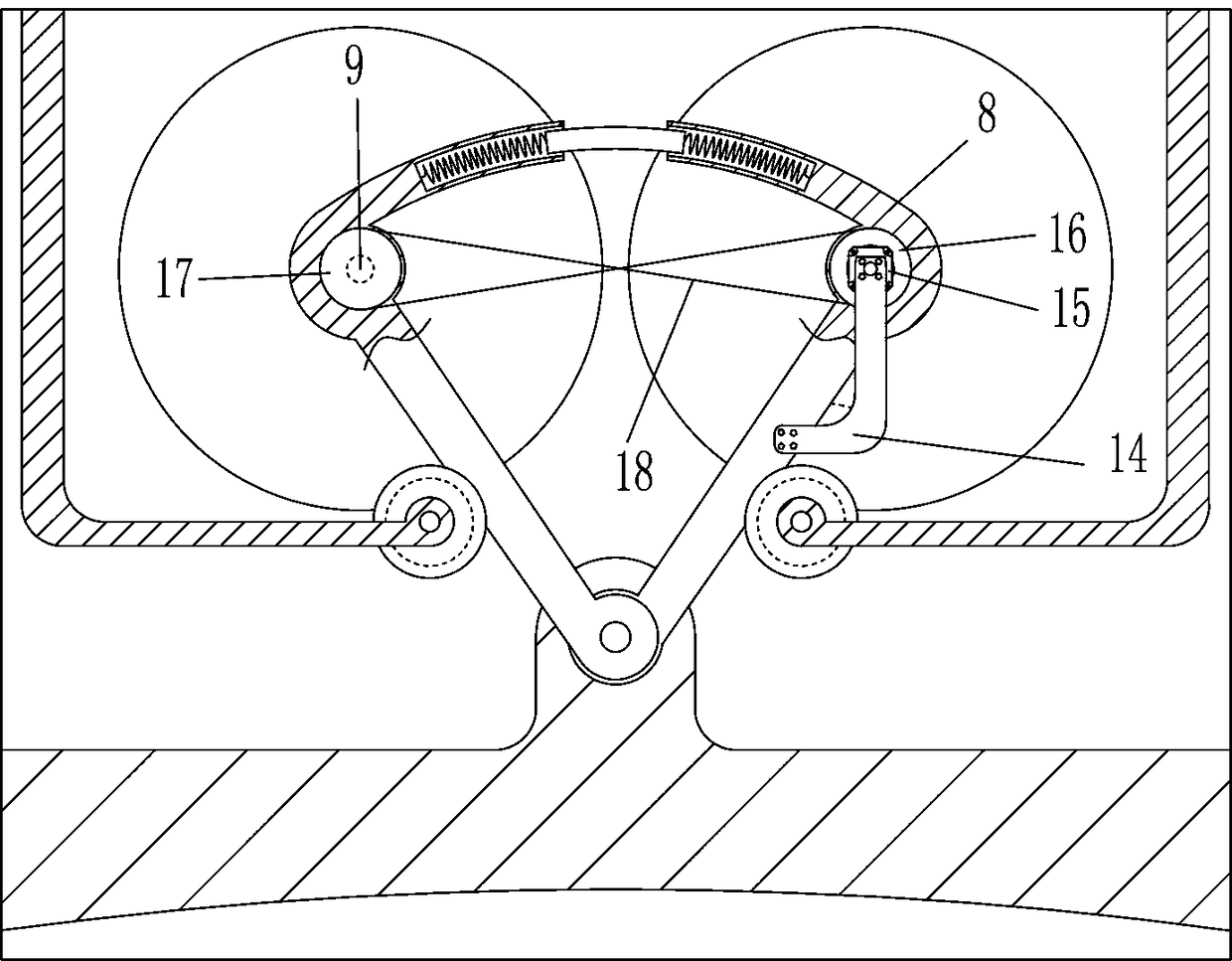

[0018] A kind of soaking and collecting equipment for textile cloth, such as Figure 1-2 As shown, it includes a support 1, a first bracket 2, a first guide rod 4, a first roller 5, a nut 6, a screw 7, a first swing rod 8, a first rotating shaft 9, a squeeze wheel 10, a first spring 12 and an arc-shaped slide bar 13, the top of the support 1 is connected with the first support 2, the middle part of the right side of the first support 2 has a first feeding port 201, and the middle part of the left side of the first support 2 has a second feeding port 202 First guide holes 3 are arranged on the left and right sides of the top of the first bracket 2, and the first guide holes 3 on the left and right sides are movably provided with first guide rods 4, and nuts are embedded in the middle of the top of the first guide rods 4. 6. The screw rod 7 is threaded inside the nut 6, the first roller 5 is provided at the left and right ends of the bottom of the first guide rod 4, and two firs...

Embodiment 3

[0021] A kind of soaking and collecting equipment for textile cloth, such as Figure 1-3 As shown, it includes a support 1, a first bracket 2, a first guide rod 4, a first roller 5, a nut 6, a screw 7, a first swing rod 8, a first rotating shaft 9, a squeeze wheel 10, a first spring 12 and an arc-shaped slide bar 13, the top of the support 1 is connected with the first support 2, the middle part of the right side of the first support 2 has a first feeding port 201, and the middle part of the left side of the first support 2 has a second feeding port 202 First guide holes 3 are arranged on the left and right sides of the top of the first bracket 2, and the first guide holes 3 on the left and right sides are movably provided with first guide rods 4, and nuts are embedded in the middle of the top of the first guide rods 4. 6. The screw rod 7 is threaded inside the nut 6, the first roller 5 is provided at the left and right ends of the bottom of the first guide rod 4, and two firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com