Gate ingot locking device

A lock device and gate technology, applied in water conservancy projects, marine engineering, coastline protection and other directions, can solve the problems of low efficiency, unsafe locking of gates, and high labor intensity, so as to ensure the safety of personnel and improve reliability. performance, prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

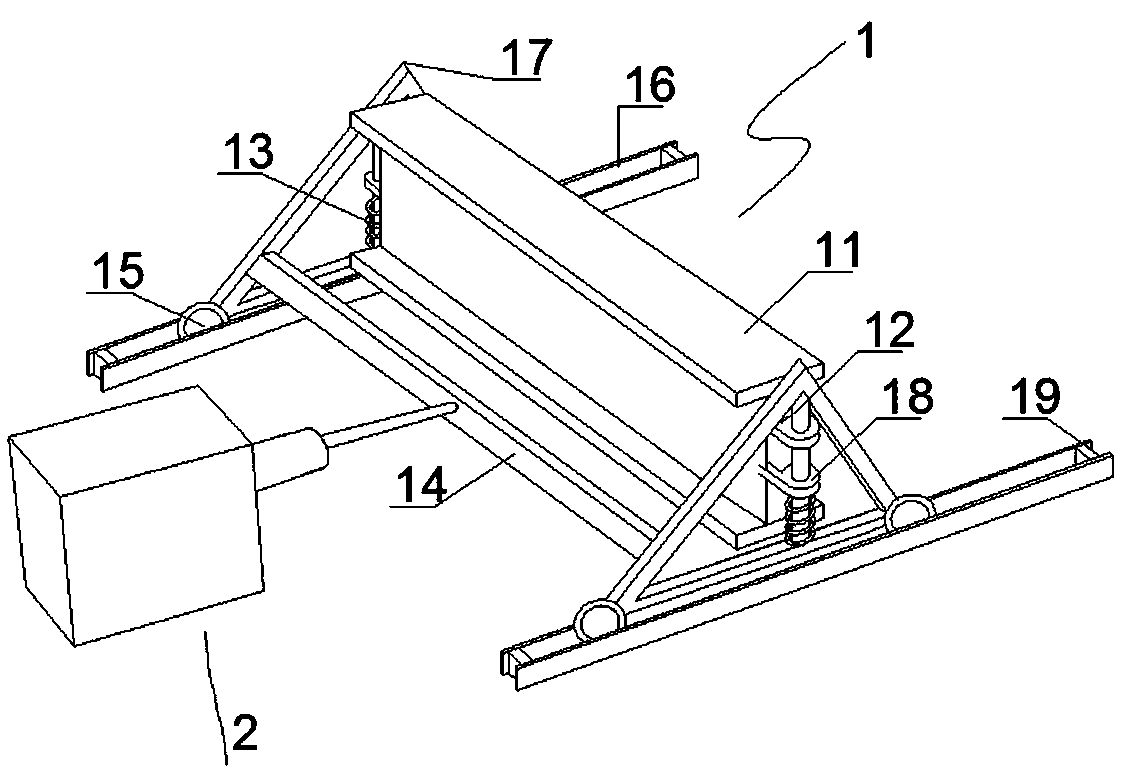

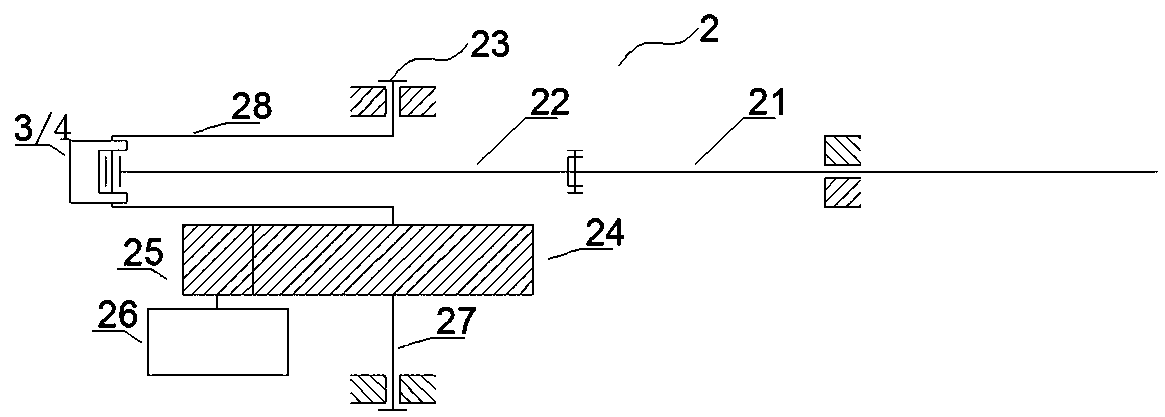

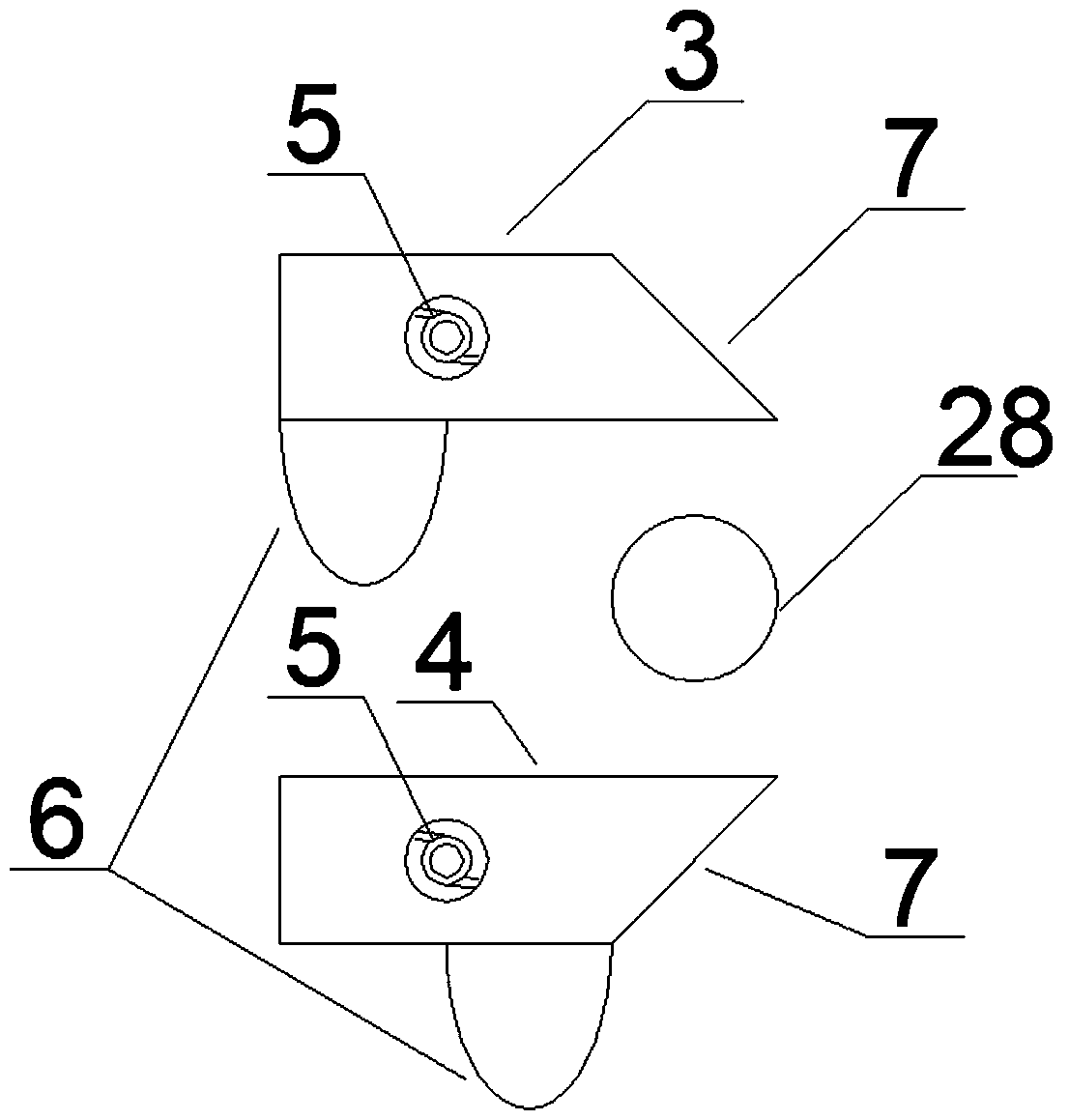

[0023] as attached figure 1 shown. A lock spindle device for a gate, comprising a spindle lock mechanism 1 and a control mechanism 2; the spindle lock mechanism 1 includes an I-beam 11, a guide rod 12, a spring 13, a connecting frame 14, a pulley 15, a slide rail 16 and two sliding Bracket 17; The two sides of described I-beam 11 are provided with outwardly protruding hole ear 18; Described hole ear 18 can move up and down to pass through guide bar 12 that is vertically fixed on the sliding bracket 17, and its lower part presses On the spring 13 pierced on the guide rod 12, the I-beam 11 is separated from the base surface; the lower part of the sliding bracket 17 is provided with a pulley 15 that can move left and right along the slide rail 16; the two sliding brackets 17 are connected by The frame 14 is fixedly connected; the control mechanism 2 is used to push and pull the connecting frame 14 to make it move left and right. The sliding bracket 17 is a triangular bracket, a...

Embodiment 2

[0026] as attached figure 1 shown. A lock spindle device for a gate, comprising a spindle lock mechanism 1 and a control mechanism 2; the spindle lock mechanism 1 includes an I-beam 11, a guide rod 12, a spring 13, a connecting frame 14, a pulley 15, a slide rail 16 and two sliding Bracket 17; The two sides of described I-beam 11 are provided with outwardly protruding hole ear 18; Described hole ear 18 can move up and down to pass through guide bar 12 that is vertically fixed on the sliding bracket 17, and its lower part presses On the spring 13 pierced on the guide rod 12, the I-beam 11 is separated from the base surface; the lower part of the sliding bracket 17 is provided with a pulley 15 that can move left and right along the slide rail 16; the two sliding brackets 17 are connected by The frame 14 is fixedly connected; the control mechanism 2 is used to push and pull the connecting frame 14 to make it move left and right. The sliding bracket 17 is a triangular bracket, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com