Tin outlet nozzle automatic washing device and washing method thereof

An automatic cleaning and feeding device technology, which is applied to cleaning methods and tools, cleaning methods using tools, auxiliary devices, etc., can solve the problems of high risk factor, low cleaning efficiency, and burns of staff, so as to ensure the safety of personnel Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

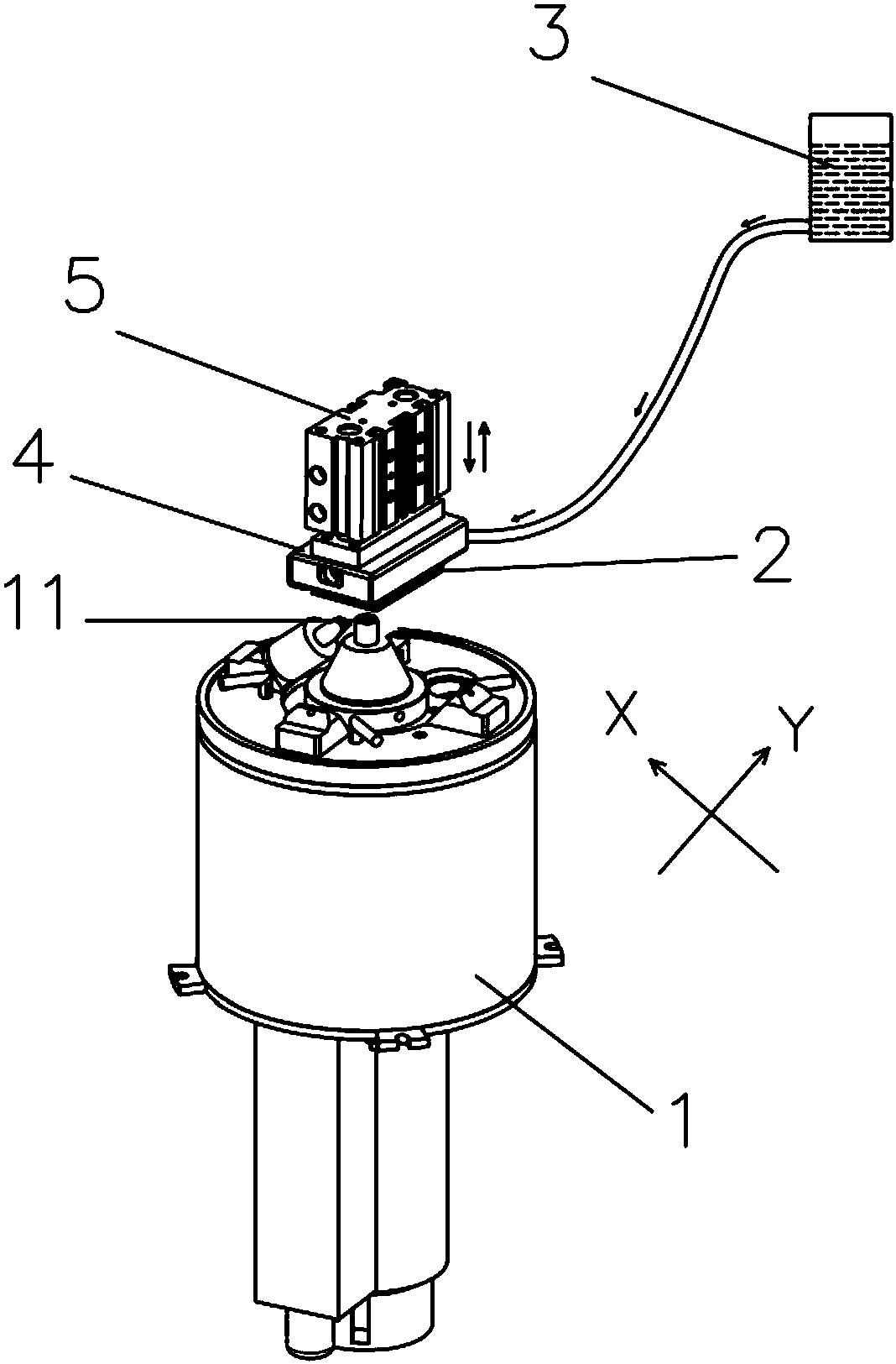

[0023] like figure 1 As shown, a tin nozzle cleaning device includes a solder furnace 1, and at least one tin nozzle 11 is arranged on the solder furnace 1, including an oxide layer removal brush 2, which is set corresponding to the tin nozzle 11, and is used for cleaning the tin nozzle. Oxide layer at 11 places; flux feeding device 3, which contains flux and is connected with oxide layer removal brush 2, so as to realize the delivery of flux to oxide layer removal brush 2; XY conveying platform, driven by solder furnace 1 connection, used to drive the solder furnace 1 to move to the oxide layer removal brush 2, and perform relative movement with the oxide layer removal brush 2 to realize the removal of the oxide layer; the control system is connected with the flux feeding device 3 and the XY conveying platform electric conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com