Railway tunnel full-section ballast bed coal suction vehicle set

A coal car group, full-section technology, applied in track cleaning, construction, cleaning methods, etc., can solve the problems of dust removal systems that do not use explosion-proof, explosion-proof and explosion-venting, hidden dangers of dust explosion, and inability to clean the entire section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0115] The present invention will be further described below in conjunction with drawings and embodiments.

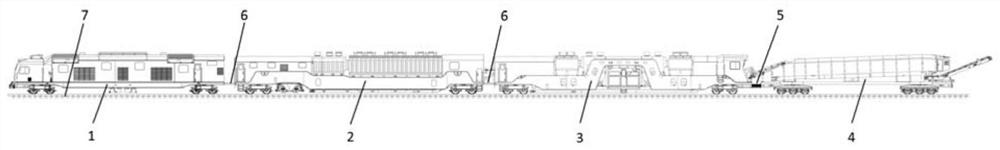

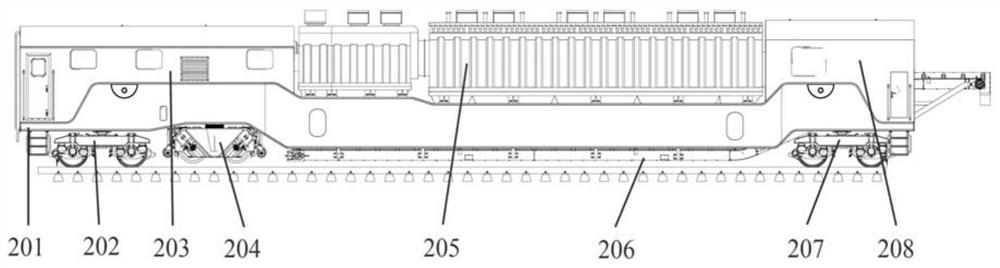

[0116] Such as figure 1 As shown, the present invention is composed of a power vehicle 1, a main suction vehicle 2, a side suction vehicle 3 and a material vehicle 4 after the coupler 5 and the connecting drawbar 6 are connected to form a working vehicle group; Traveling bogie 107, third driving traveling bogie 202, fourth driving traveling bogie 207, fifth driven traveling bogie 302, sixth driven traveling bogie 311, material truck first traveling bogie 402 and material truck The second bogie 404 runs on the rail 7 .

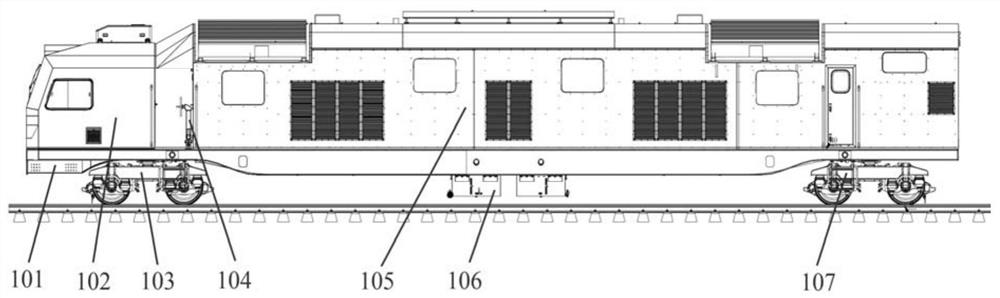

[0117] Such as figure 2 As shown, the power vehicle frame 101 is installed on the first driving traveling bogie 103 and the second driving traveling bogie 107; the front end of the power vehicle frame 101 is fixed with a front cab 102; the power room 105 is located behind the front cab 102 The hand brake 104 is located in the front of the power room ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com