A Method for Strengthening the Concrete Strength of Beam Supports

A technology of concrete strength and reinforcing beams, applied in construction, building maintenance, building construction, etc., can solve the problems of prestress lag, increase structural self-weight, structural aging, etc., to reduce the peak internal force, improve bearing capacity, and improve bending resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method for strengthening the concrete strength of a beam support, the steps are as follows:

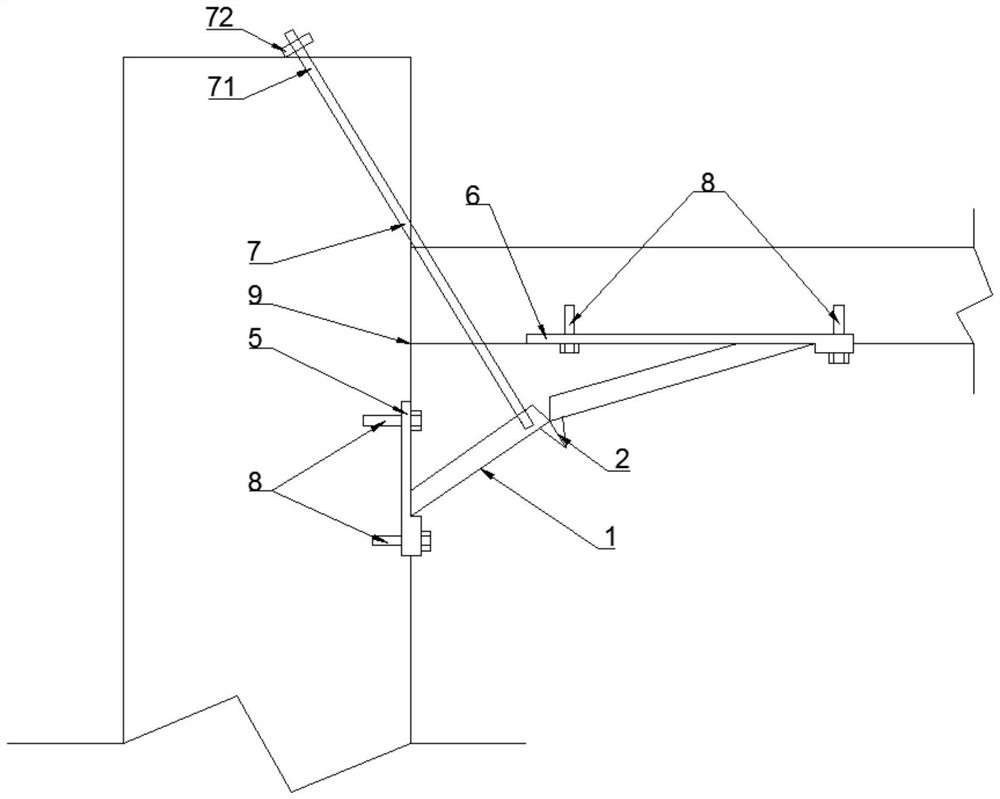

[0042] (1) Refer to figure 1 The lower thrust anchor plate 5 is fixedly installed on the side of the support 220mm below the beam support node 9, the upper thrust anchor plate 6 is fixedly installed on the lower part of the beam 604mm away from the beam support node 9, and the upper and lower thrust The anchor plates are all provided with thrust grooves, the upper thrust groove 61, the lower thrust groove 51 and the node of the beam support form a right-angled triangle reinforcement area, and the angle between the line connecting the upper and lower thrust grooves and the beam is 20°;

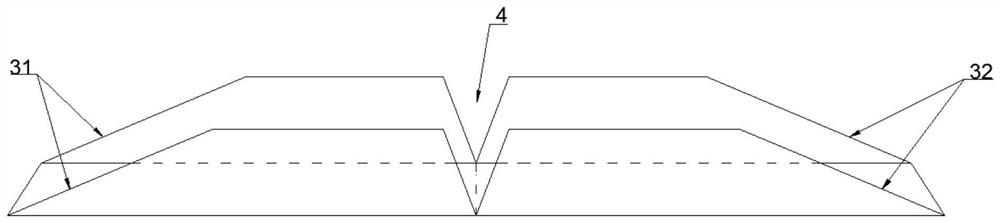

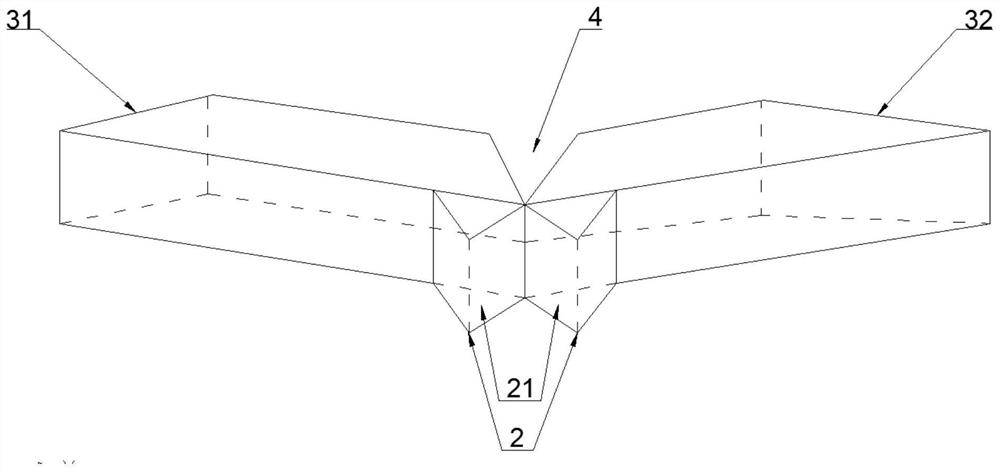

[0043] (2) Refer to figure 2 , to prepare pre-bent channel steel, get a section of channel steel 1, the channel steel type used in the present embodiment is 12, the size is h120mm b53mm d5.3mm, and its length is 648mm, the two ends of channel steel 1 are cut off the flange respectively, One e...

Embodiment 2

[0047] The fixing method of the upper and lower thrust anchor plates has the following steps:

[0048] (1) Excavate the concrete protective layer at the installation position of the upper and lower thrust anchor plates;

[0049] (2) Apply structural adhesive to the mounting surface of the thrust anchor plate. The structural adhesive used in this example is sj168 silicone weather-resistant sealant, and the thickness of the structural adhesive is 5-7mm. Paste the thrust anchor plate on the on the beam support.

[0050] (3) After 2-3 hours, the structural glue is basically hardened to produce enough sticky force, and the reinforcement glue is injected into the installation hole of the thrust anchor plate, and then the bolt 8 is implanted and tightened. The bolts used in this embodiment are M16*80, curing and curing.

Embodiment 3

[0052] refer to figure 2 , the notch of the pre-bending groove 4 in this embodiment is triangular.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com