Shield machine stabilizing device and shield machine

A stabilizing device and shield machine technology, which is applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems of small friction and inability to effectively suppress the roll and vibration of the shield machine, so as to reduce resistance and improve the overall Stabilizing effect, anti-rolling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereby.

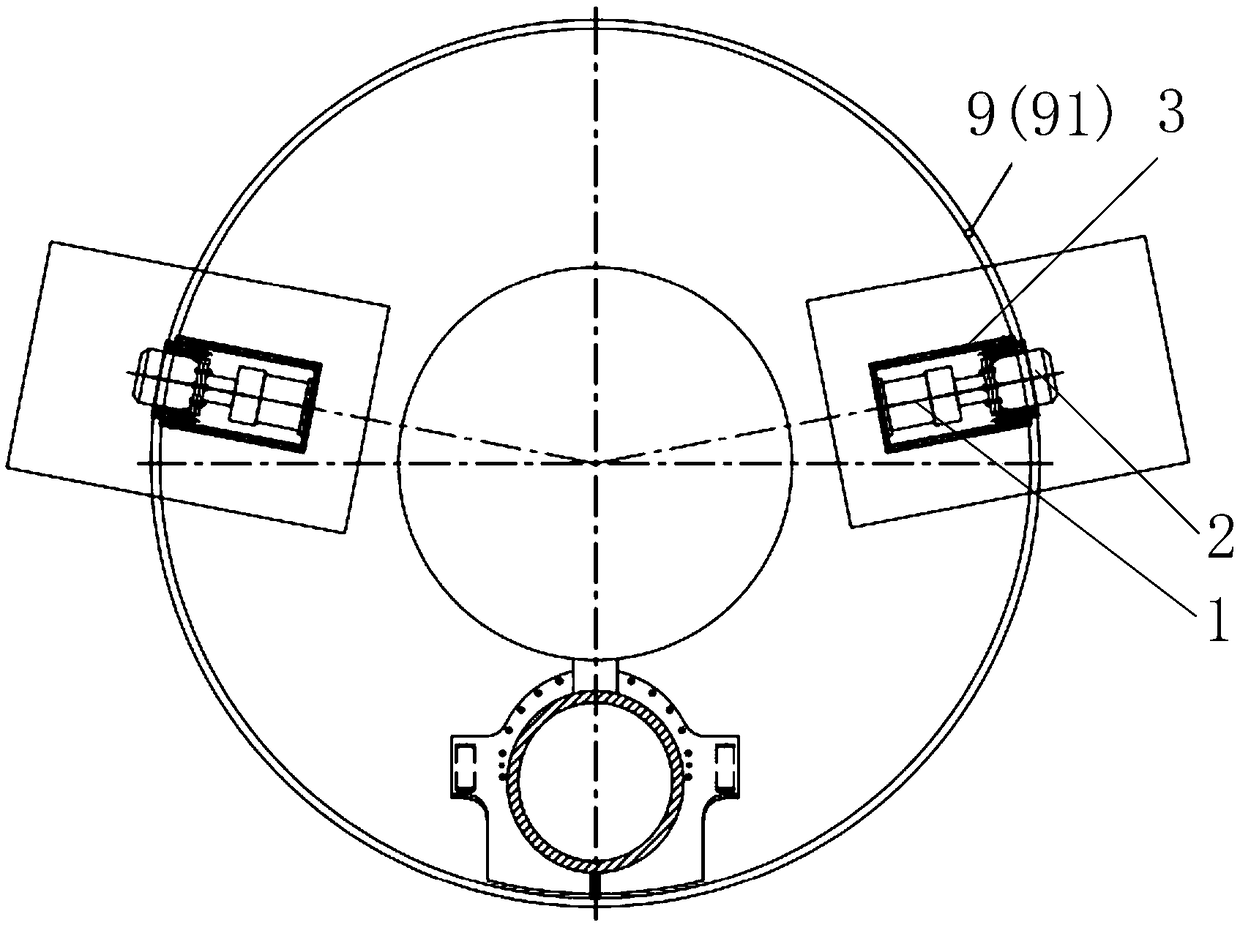

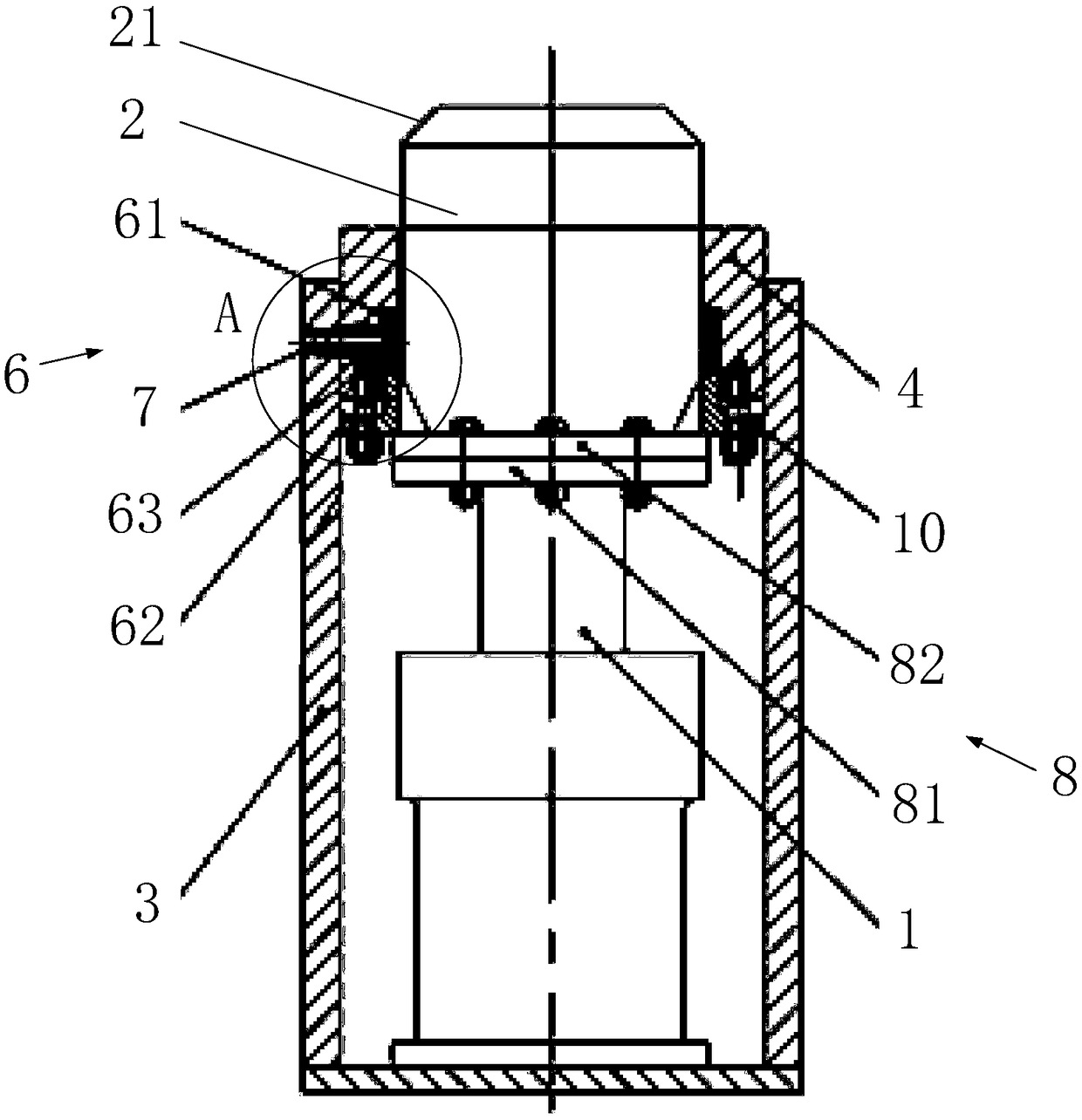

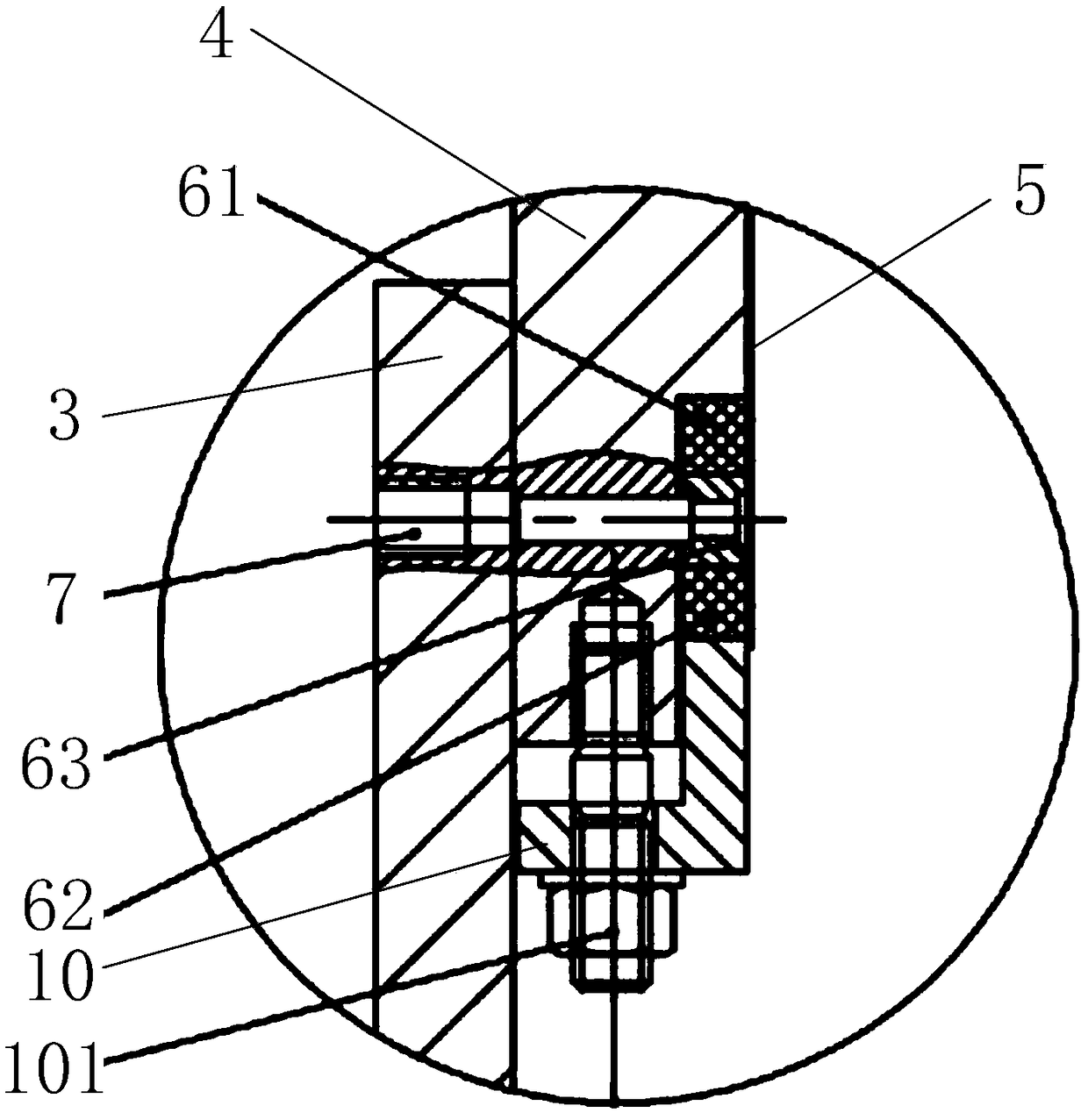

[0027] like Figure 1 to Figure 4 As shown, the stabilizing device of the shield machine in this embodiment includes a telescopic drive member 1 and a rectangular support shoe 2, the rectangular support shoe 2 is arranged at the working end of the telescopic drive member 1, and the rectangular support shoe 2 is normally excavated in the shield machine 9 When working, it is in an extended state and inserted into the rock-soil medium around the shield body 91 . Wherein, the long sides of the rectangular support shoes 2 are arranged along the rotation direction of the shield machine 9 , and the short sides of the rectangular support shoes 2 are arranged along the excavation direction of the shield machine 9 . It makes the force bearing area of the shield machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com