Beating type compound cloth adhesive powder extractor

A composite cloth and extraction machine technology, applied in sampling, sampling devices, measuring devices, etc., can solve the problems of difficult extraction, low efficiency, and damage to the respiratory tract of workers, and achieve the effect of good extraction effect and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

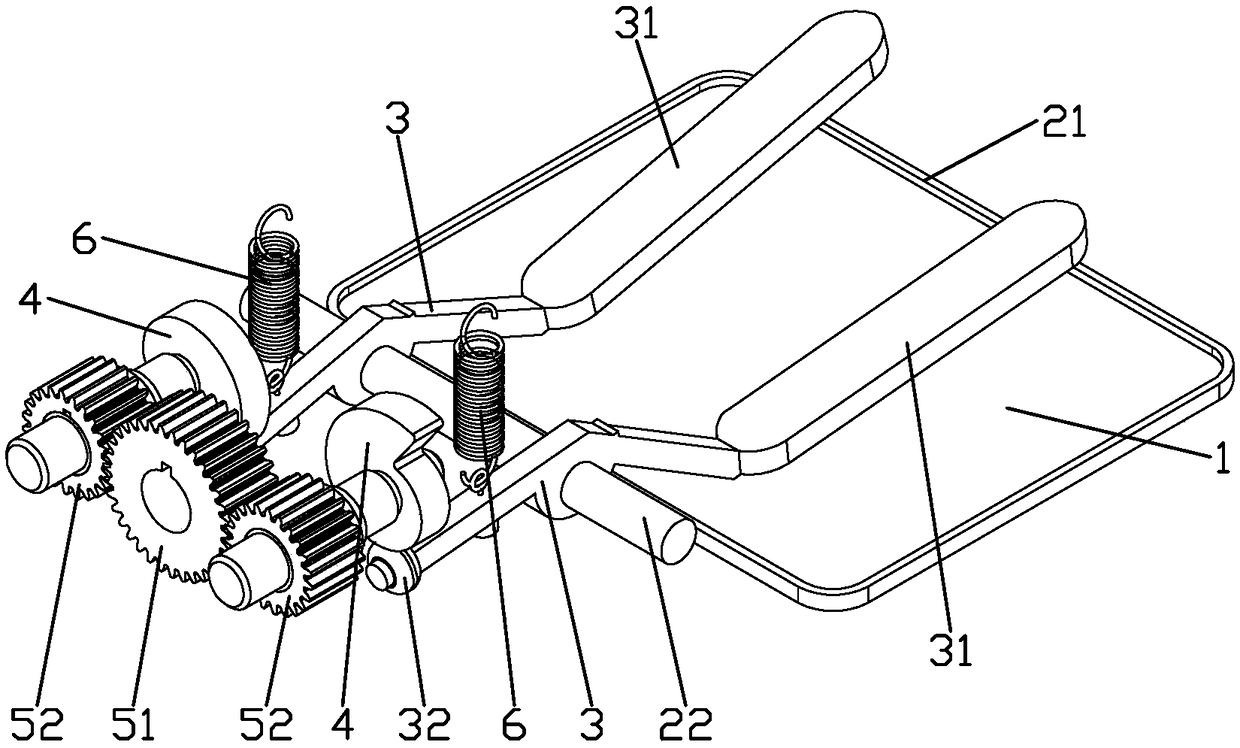

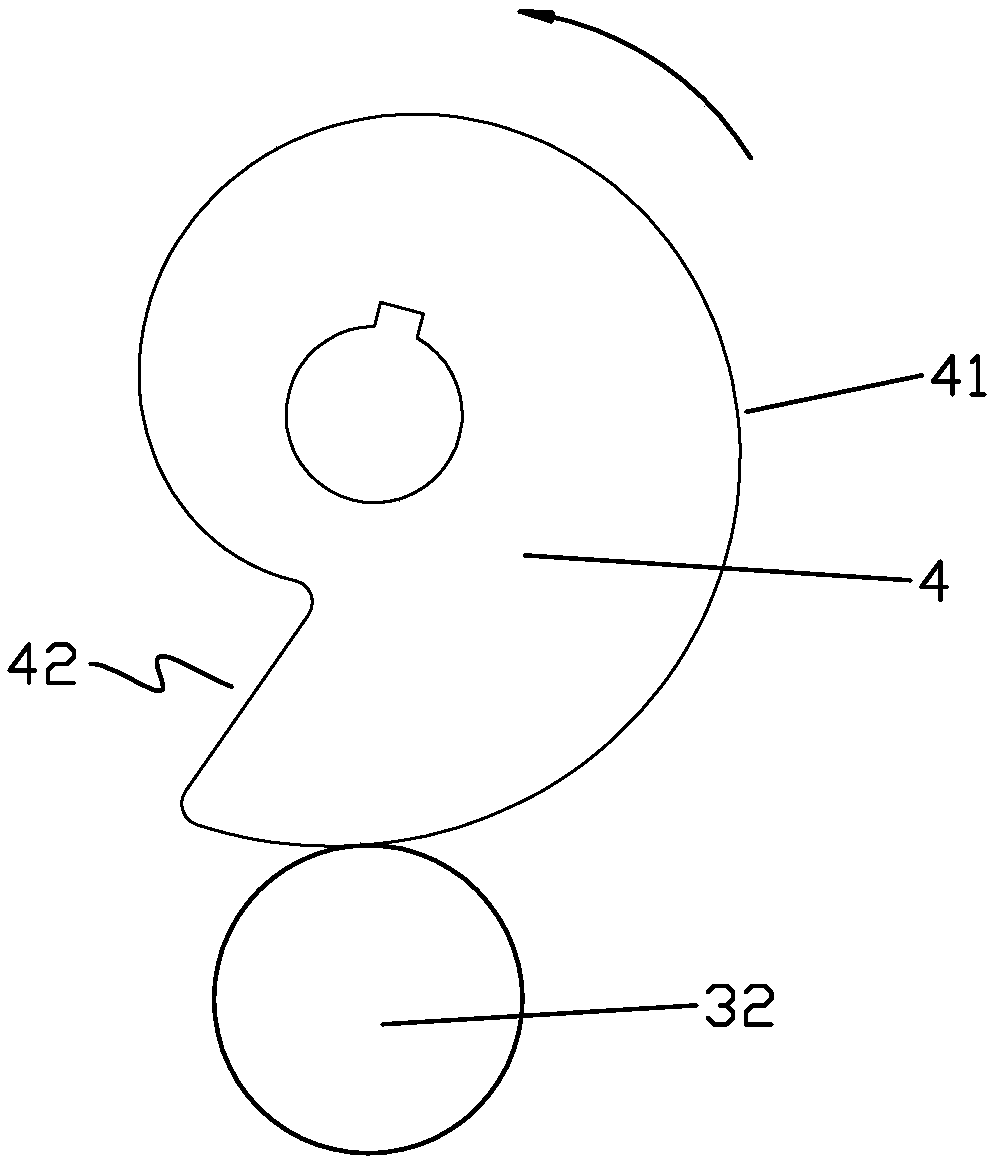

[0017] refer to figure 1 and figure 2 , the embodiment of the present invention proposes a kind of beating type composite cloth rubber powder extraction machine, comprises frame (not shown), and described frame is provided with and is used for fixing the composite cloth fixing rack 21 of composite cloth 1, and composite cloth 1 Expanded and fixed on the composite cloth fixing frame 21, the frame is provided with a driving device and a racket bar 3 that can swing on the frame to beat the composite cloth 1, and the output end of the driving device is connected with a The cam 4 for the swing of the racket shaft 1 . Using the racket 3 to repeatedly pat the composite cloth 1 is similar to manual slapping, and has good extraction effect, high efficiency, and is environmentally friendly and healthy.

[0018] ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com